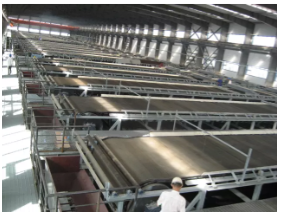

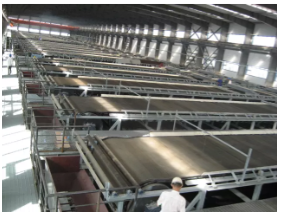

The Rubber vacuum belt filter stands as a pivotal piece of solid‑liquid separation equipment across mining, chemical, environmental, and industrial processing industries due to its robust continuous filtration performance and adaptability. A specialized variant known as the Rubber Belt Vacuum Filter enhances this capability by applying vacuum suction across a continuous rubber belt to separate solids from liquids efficiently.

However, beyond manufacturing high‑performing filtration equipment, leading suppliers differentiate themselves through the depth and quality of technical support they provide. This article explores key technical support features offered by Rubber belt filter suppliers, including consulting, installation assistance, training, maintenance programs, spare parts provision, and digital tools.

Overview — Why Technical Support Matters for Rubber Belt Filters

A Rubber belt filter is more than just hardware — it is part of an integrated solid‑liquid separation equipment solution. Downtime, suboptimal performance, or improper configuration can lead to efficiency loss, higher operational costs, and safety risks. Suppliers offering comprehensive technical support ensure customers can maximize uptime, maintain consistent performance, and reduce lifecycle costs.

Here are the broad categories of technical support most impactful to users:

Pre‑Sales Consulting & Process Evaluation

Installation, Commissioning, and Start‑Up Support

Training & Operational Guidance

Maintenance and Preventative Programs

Spare Parts Supply & Media Support

Remote Diagnostics and Digital Tools

Customization and Engineering Services

Pre‑Sales Consulting & Process Evaluation

Before purchasing a Rubber belt filter, practical technical insights into whether the equipment fits a plant’s process are essential.

Technical Assessment Services

Experienced suppliers often conduct technical consulting before a sale to evaluate a customer’s slurry characteristics, solids load, particle size distributions, and moisture loss targets. These insights ensure the recommended Rubber Belt Vacuum Filter configuration — such as belt width, vacuum zone settings, filter cloth material, and automation features — aligns with the process goals.

Feed Characterization — Suppliers may analyze slurry lab samples to determine optimal equipment specifications.

Filtration Simulations — Tools or expert guidance predict performance under specific conditions.

ROI and Efficiency Projections — Helps justify capital expenditure.

Pre‑sales consulting helps minimize specification errors and ensures the right solid‑liquid separation equipment is selected for the job.

Installation, Commissioning, and Start‑Up Support

Purchasing and delivering a Rubber belt filter is just the start — professional installation and commissioning are crucial to realizing its full benefits.

Installation Assistance

Top suppliers coordinate equipment installation, including:

On‑site support during assembly

Alignment verification of the filtration belt and vacuum system

Electrical, pneumatic, and automation integration

Commissioning

The commissioning phase typically includes:

| Commissioning Step | Supplier Action |

| Belt and cloth alignment | Verified to avoid tracking issues |

| Vacuum system calibration | Set to optimal pressure range depending on slurry |

| Safety systems test | Ensure emergency stops, guards, and sensors operate correctly |

| Performance validation | Run test filtration cycles to confirm output parameters |

This phase ensures that the Rubber belt filter operates to design standards and reduces early operational issues.

Training & Operational Guidance

One of the most valuable technical support services a supplier can provide is comprehensive training.

Training Features

Suppliers often deliver:

Operator training — Hands‑on or classroom sessions to understand machine operation.

Maintenance training — How to inspect belts, vacuum seals, and wear components.

Troubleshooting workshops — To diagnose and resolve common issues quickly.

Training empowers in‑house teams to handle routine tasks safely and effectively without over‑reliance on external support.

Maintenance and Preventative Programs

A Rubber belt filter involves moving parts, vacuum seals, filter cloths, and belts that will wear over time. Preventative maintenance keeps systems running smoothly.

Structured Maintenance Programs

Leading suppliers establish maintenance programs that include:

Scheduled inspections — Belt wear, pump condition, vacuum integrity.

Wear part replacement planning — Based on runtime metrics.

Preventative checks — Reduces unplanned downtime.

Such programs are critical for continuous filtration systems like Rubber belt vacuum filters.

Benefits of Preventative Maintenance

Extends equipment lifecycle

Reduces unplanned stoppages

Improves consistent filtrate quality

Reduces total maintenance costs

This aligns with what many filtration equipment vendors identify as essential support for long‑term reliability and performance consistency in solid‑liquid separation applications.

Spare Parts & Consumables Provision

Another key support function is providing reliable access to spare parts, consumables, and filter media — particularly filter cloths and belts.

Spare Parts Inventory

Suppliers may maintain an inventory of:

Availability of parts is crucial because delays in spare part delivery can halt entire production lines.

Filter Media & Belt Options

For a Rubber belt filter, filter media selection influences performance. Many suppliers provide:

Different cloth materials for varied particle sizes

Custom‑engineered belts for unique process chemistries

Specialty belts with chemical‑resistant properties

Ensuring access to the correct components dramatically improves equipment uptime and performance.

Remote Diagnostics and Digital Tools

In modern industrial environments, remote support and data integration are vital.

Remote Monitoring

Sophisticated suppliers offer remote diagnostics via IoT or PLC/DCS systems that track:

Vacuum levels

Belt speed

Filtrate clarity signals

System alarms

Remote systems help identify issues before they escalate to downtime.

Digital Support Tools

Online dashboards and alerts allow:

Real‑time performance tracking

Alerts when maintenance is due

Historical trend analysis

This digital approach aligns with emerging trends toward Industry 4.0 and predictive maintenance models.

Engineering Customization and Upgrades

Every plant has unique filtration needs. Leading suppliers provide engineering and customization services such as:

Custom belt widths

Specialized vacuum chamber designs

Tailored cake washing stages

Modular expansions for future process growth

Modular design not only simplifies upgrades but also reduces lead times and enables staged capital investments.

Data‑Driven Comparison of Technical Support Features

Below is a comparison chart illustrating how Rubber belt filter suppliers typically stack up in terms of technical support services.

| Technical Support Feature | Description | Typical Value to User |

| Pre‑Sales Process Evaluation | Analysis of slurry, filtration needs | Ensures correct equipment specification |

| Installation & Commissioning | On‑site setup & performance validation | Reduces start‑up delays |

| Training Programs | Operator & maintenance training | Builds in‑house expertise |

| Scheduled Maintenance | Preventative checks & plans | Reduces breakdowns |

| Spare Parts Availability | On‑hand stock or rapid delivery | Minimizes downtime |

| Remote Monitoring | IoT & digital diagnostic support | Predictive issue detection |

| Engineering Customization | Tailored solutions | Better performance for unique feeds |

By selecting suppliers with comprehensive technical support offerings, users can achieve higher equipment utilization, more reliable performance, and improved operational efficiency.

Emerging Trends in Supplier Support

Technical support is evolving beyond mere service response to a data‑driven, proactive partnership.

Automation and Integration

Suppliers increasingly embed automation into Rubber belt vacuum filter controls, enabling remote monitoring and real‑time performance adjustments. This trend aligns with modern plant digital transformation strategies.

Predictive Support Models

Using data analytics and historical performance, suppliers can predict when components will fail and recommend maintenance or parts replacement before an issue occurs — reducing downtime and optimizing lifecycles.

Collaborative Partnerships

Top suppliers act as process partners with regular performance reviews, continuous improvement recommendations, and tailored optimization plans — far beyond traditional break‑fix support.

Case Example — What Comprehensive Support Looks Like

Imagine a mining operation handling gypsum tailings with a Rubber belt filter:

Supplier Pre‑Sales Review identifies slurry properties and recommends belt width and vacuum stages.

Installation Team configures the system and verifies filtration efficiency.

Training Sessions empower operators to run the system, troubleshoot alarms, and reset vacuum stages.

Preventative Maintenance Plan schedules quarterly inspections of belts and vacuum seals.

Remote Monitoring Tools detect a decline in vacuum levels, triggering predictive maintenance alerts.

Engineering Support modifies cake washing zones to meet a new specification.

The result is a high‑performing system with minimal downtime and predictable performance.

Conclusion — The Value of Strong Supplier Technical Support

Technical support for Rubber belt filters extends well beyond equipment delivery. It encompasses a suite of services that enhance operational performance, reliability, and lifecycle economics. From pre‑sales consulting and supplier‑led commissioning to training, maintenance programs, spare parts provisioning, and digital monitoring, these services ensure users get maximum return on their filtration investment.

By choosing suppliers that provide robust technical support, manufacturers and processors can unlock the full potential of their Rubber Belt Vacuum Filters and other solid‑liquid separation equipment while minimizing risks, downtime, and unexpected costs.

FAQs About Rubber Belt Filter Supplier Technical Support

1. What type of spare parts should I expect suppliers to stock for Rubber belt filters?

Suppliers typically stock vacuum seals, filter belts, filter cloths, rollers, and vacuum pump components to minimize downtime caused by part failures.

2. How does remote monitoring improve support for Rubber belt filters?

Remote diagnostics enable suppliers and operators to track performance in real time, identify abnormal behavior, and recommend proactive maintenance before failures occur.

3. Do suppliers offer customized engineering for unique slurry challenges?

Yes, many suppliers provide tailored engineering services, including belt width adjustments, custom filtration zones, and automation integration, to meet specific process needs.

4. What kind of training do suppliers provide for Rubber belt filter users?

Training often includes equipment operation, safety procedures, maintenance tasks, and troubleshooting techniques to ensure on‑site teams can run and care for the machinery effectively.

5. Can suppliers help optimize existing Rubber belt filters already in operation?

Leading suppliers offer performance audits, retrofit options, and ongoing improvement recommendations to boost filtration efficiency and extend equipment life.

English

English