- Home

- Products

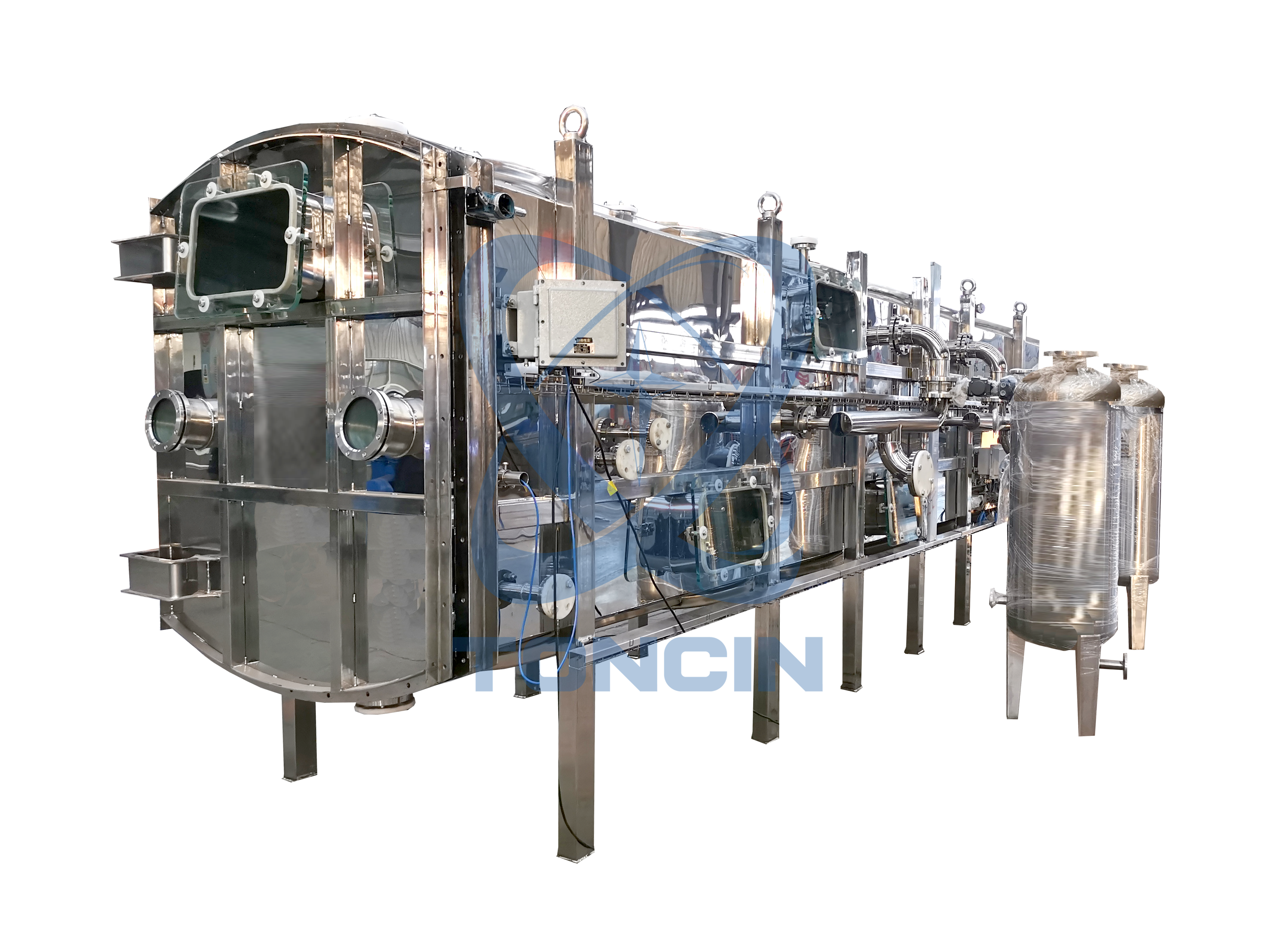

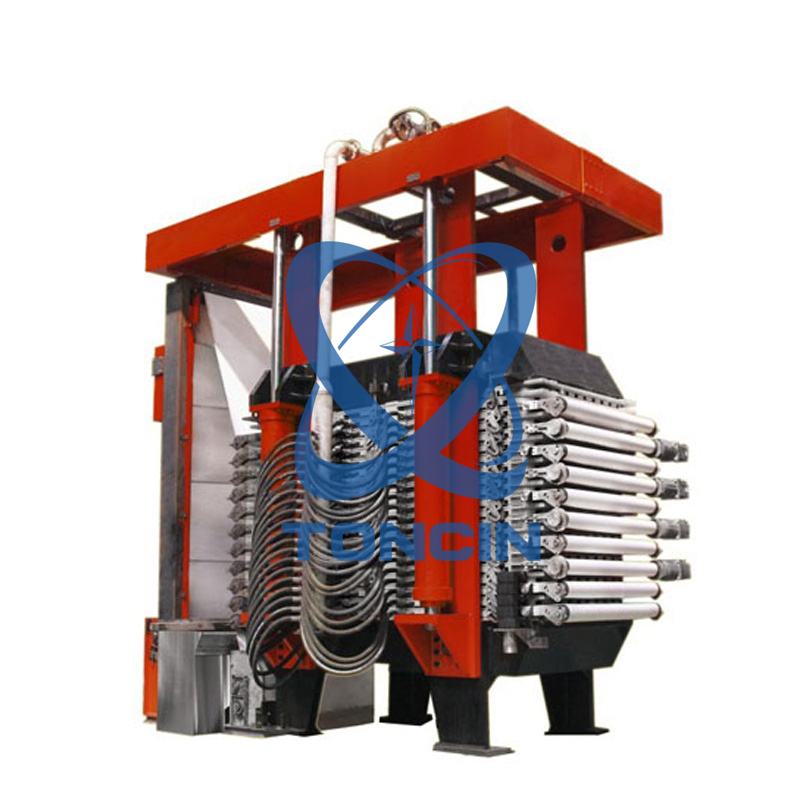

- Solid Liquid Seperation Equipment

- Automatic Packaging Equipment

- Stretch Wrapping Machine

- Online Stretch Wrapping Machine

- Rotary Stretch Wrapping Machine

- Top Sheet Machine

- Mini Stretch Wrapping Machine

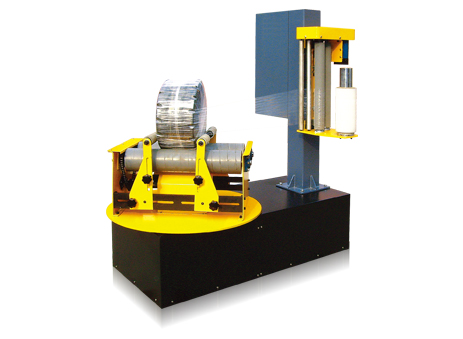

- Reel Type Stretch Wrapping Machine

- High Speed Ring Type Stretch Wrapping Machine

- Horizontal Stretch Wrapping Machine

- Six Side Packaging Machine

- Intelligent Conveying and Packaging System

- Intelligent Conveying Equipment

- Dams And Conveyor Belts

- Hot

- About Us

- Industry

- Resources

- news

- Project

- Contact Us

English

English