The belt filter press is one kind of solid-liquid separation equipment that is useful to separate the solid particles with size more than micron to millimeter from the liquid (water). The advantages of this equipment is highly automation, simple and easy maintenance and low labour intensity.

| Availability: | |

|---|---|

| Quantity: | |

DY

Toncin

Product Introduction:

The belt filter press utilizes mechanical compression to achieve highly efficient solid-liquid separation. This advanced system seamlessly integrates the processes of filtration, cloth cleaning, and residue discharge, delivering exceptional performance with high efficiency and output. It offers excellent rinsing results, low moisture content in the filtered solids, intelligent operation, and minimal maintenance costs. The belt filter press is versatile and suitable for processing sludge from a wide range of industries, including municipal wastewater treatment, textile dyeing and printing, electroplating, paper manufacturing, leather processing, brewing, coal washing, chemical production, pharmaceuticals, ceramics, and more.

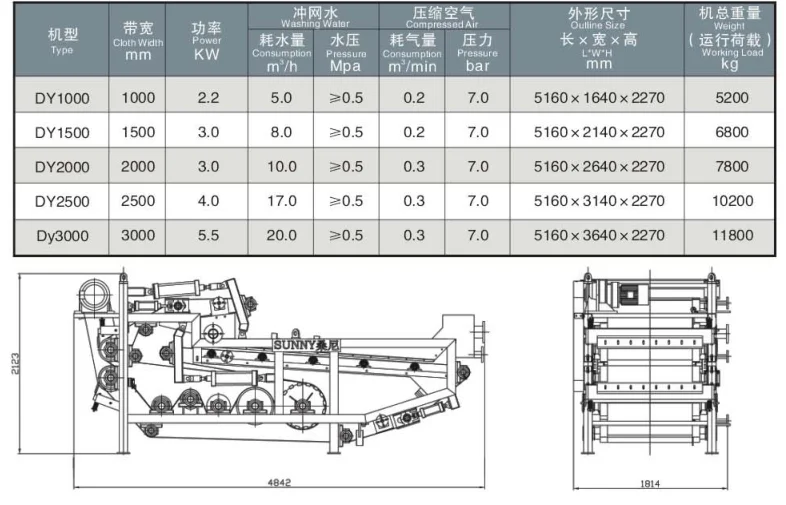

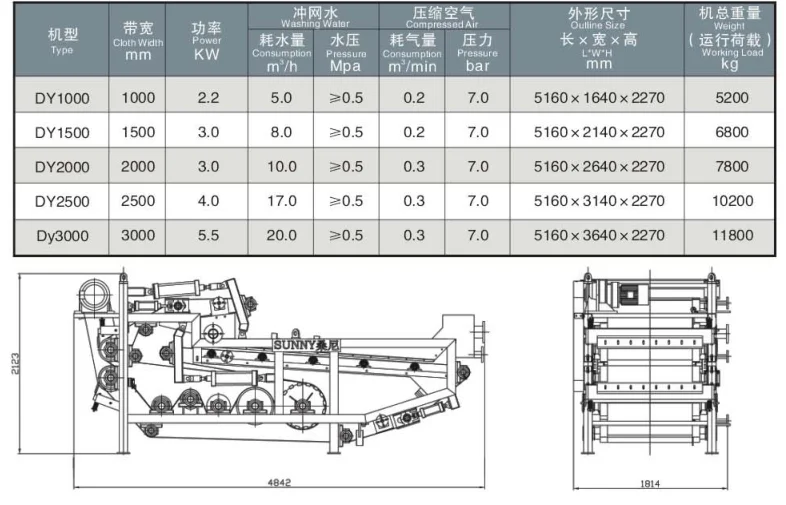

Product Parameters:

Operating Principle:

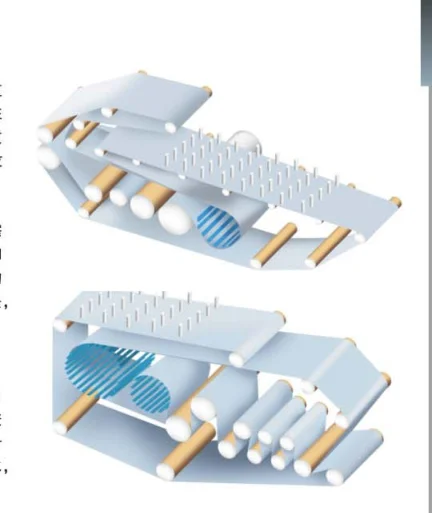

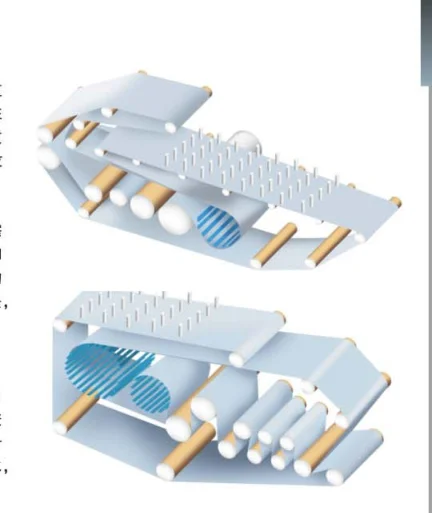

Preparation Stage

Following the flocculation process, the sludge is evenly distributed onto the filter cloth. A significant portion of the water separates from the flocculated sludge under the influence of gravity. The effectiveness of this stage depends on factors such as the quality of the filter cloth, the characteristics of the sludge, and the efficiency of the flocculation process.

Wedge Pre-Press Dewatering Stage

After gravitational dewatering, the sludge's flowability is significantly reduced, though it remains insufficient for direct roller pressing. During the wedge pre-press dewatering stage, surface water is further removed, and the sludge's flowability is adjusted to an optimal condition, ensuring it is adequately prepared for the subsequent pressing stage.

Squeezing Dewatering Stage

The sludge is then conveyed into the squeezing roller system. The rollers are designed with gradually decreasing sizes, which progressively increase the external pressure applied to the sludge. This step ensures efficient dewatering, resulting in a solid material with significantly reduced moisture content.

Product Advantages:

Compared to traditional dewatering equipment, this system offers continuous production, high processing capacity, and excellent dewatering performance. Its scientific and rational design, combined with a high degree of automation, reduces labor intensity while ensuring easy operation and maintenance.

The main components are constructed from stainless steel, providing superior corrosion resistance and durability. The extrusion rollers are fully encapsulated (including the ends), ensuring effective dewatering and extending the lifespan of the filter belt.

The system features a unique mesh belt tensioning and biasing mechanism, which is both flexible and reliable, guaranteeing smooth and automatic operation. Its innovative integrated design significantly enhances dewatering efficiency and ensures effective filter cake release.

Additionally, the supporting equipment and system processes are advanced and well-optimized, requiring minimal chemical additives and resulting in lower operational costs.

Service Support:

Whole Technological Design

Toncin determines reasonable plans and selections by conducting more systematic laboratory tests, semi-industrialization tests and theoretical analysis calculations and adopting appropriate methods in light of the actual problems faced by customers. And it determines specific parameters through laboratory tests and semi-industrial tests.

Project Construction

Toncin can provide customers with integrated project services for its perfect project management system and experienced high-quality team and can also provide customers with its best services in achieving the ultimate project goal by carrying out the management work on the project quality, schedule, safety, cost, procurement, information files, organization and coordination etc. according to customer’s contractual documents. Toncin contracts the design, procurement, construction and trials etc. for the entire process or some certain stages of the construction project according to the contract and takes full liability for the quality, safety, duration and cost etc. of the contracted project.

Response Time and After-sales Services

If any failure due to a defect has occurred during the warranty period, our company has given the following response and promise: to respond within 12 hours and rush to the domestic scene within 72 hours. With a rigorous and efficient service architecture, diverse and flexible service and response means, Toncin is capable of providing response service up to 7* 24 hours to ensure that users can get help at any time during the warranty period.

Product Introduction:

The belt filter press utilizes mechanical compression to achieve highly efficient solid-liquid separation. This advanced system seamlessly integrates the processes of filtration, cloth cleaning, and residue discharge, delivering exceptional performance with high efficiency and output. It offers excellent rinsing results, low moisture content in the filtered solids, intelligent operation, and minimal maintenance costs. The belt filter press is versatile and suitable for processing sludge from a wide range of industries, including municipal wastewater treatment, textile dyeing and printing, electroplating, paper manufacturing, leather processing, brewing, coal washing, chemical production, pharmaceuticals, ceramics, and more.

Product Parameters:

Operating Principle:

Preparation Stage

Following the flocculation process, the sludge is evenly distributed onto the filter cloth. A significant portion of the water separates from the flocculated sludge under the influence of gravity. The effectiveness of this stage depends on factors such as the quality of the filter cloth, the characteristics of the sludge, and the efficiency of the flocculation process.

Wedge Pre-Press Dewatering Stage

After gravitational dewatering, the sludge's flowability is significantly reduced, though it remains insufficient for direct roller pressing. During the wedge pre-press dewatering stage, surface water is further removed, and the sludge's flowability is adjusted to an optimal condition, ensuring it is adequately prepared for the subsequent pressing stage.

Squeezing Dewatering Stage

The sludge is then conveyed into the squeezing roller system. The rollers are designed with gradually decreasing sizes, which progressively increase the external pressure applied to the sludge. This step ensures efficient dewatering, resulting in a solid material with significantly reduced moisture content.

Product Advantages:

Compared to traditional dewatering equipment, this system offers continuous production, high processing capacity, and excellent dewatering performance. Its scientific and rational design, combined with a high degree of automation, reduces labor intensity while ensuring easy operation and maintenance.

The main components are constructed from stainless steel, providing superior corrosion resistance and durability. The extrusion rollers are fully encapsulated (including the ends), ensuring effective dewatering and extending the lifespan of the filter belt.

The system features a unique mesh belt tensioning and biasing mechanism, which is both flexible and reliable, guaranteeing smooth and automatic operation. Its innovative integrated design significantly enhances dewatering efficiency and ensures effective filter cake release.

Additionally, the supporting equipment and system processes are advanced and well-optimized, requiring minimal chemical additives and resulting in lower operational costs.

Service Support:

Whole Technological Design

Toncin determines reasonable plans and selections by conducting more systematic laboratory tests, semi-industrialization tests and theoretical analysis calculations and adopting appropriate methods in light of the actual problems faced by customers. And it determines specific parameters through laboratory tests and semi-industrial tests.

Project Construction

Toncin can provide customers with integrated project services for its perfect project management system and experienced high-quality team and can also provide customers with its best services in achieving the ultimate project goal by carrying out the management work on the project quality, schedule, safety, cost, procurement, information files, organization and coordination etc. according to customer’s contractual documents. Toncin contracts the design, procurement, construction and trials etc. for the entire process or some certain stages of the construction project according to the contract and takes full liability for the quality, safety, duration and cost etc. of the contracted project.

Response Time and After-sales Services

If any failure due to a defect has occurred during the warranty period, our company has given the following response and promise: to respond within 12 hours and rush to the domestic scene within 72 hours. With a rigorous and efficient service architecture, diverse and flexible service and response means, Toncin is capable of providing response service up to 7* 24 hours to ensure that users can get help at any time during the warranty period.