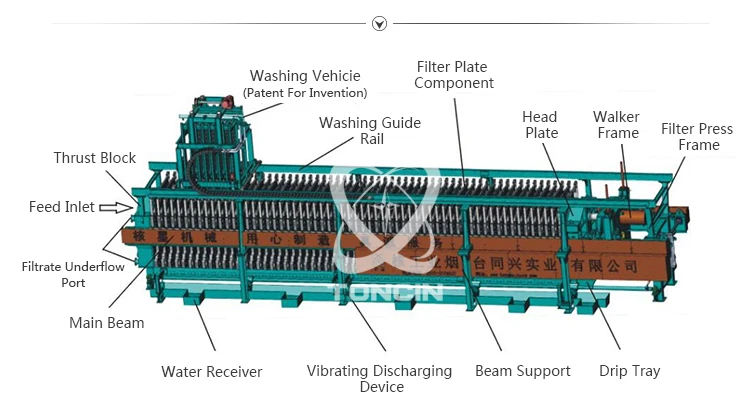

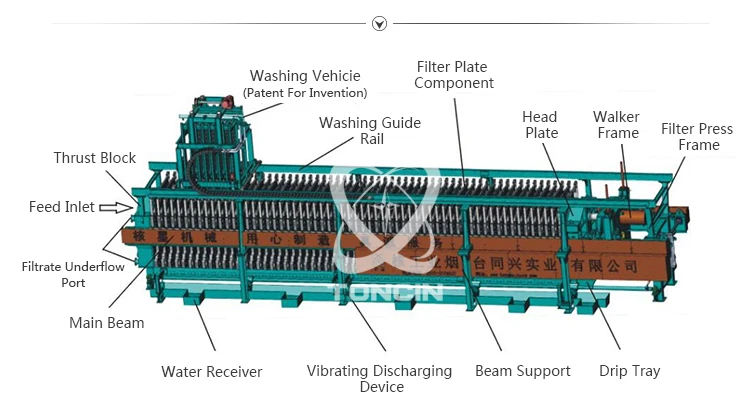

The SSPF smart row plate filter press is a fast opening and closing plate filter press which mainly consists of the electrical control system, hydraulic control system and the main engine.

| Availability: | |

|---|---|

| Quantity: | |

SSPF Filter Press

Toncin

SSPF Customized Horizontal Smart Filter Press for Solid-Liquid Separation in Mining Processing

The SSPF smart row plate filter press is a state-of-the-art solution designed for efficient solid-liquid separation in mining and industrial processing. This advanced equipment integrates an electrical control system, hydraulic control system, and a robust main engine to deliver high-performance filtration and dehydration. Its fast opening and closing mechanism, combined with intelligent automation, ensures optimal operational efficiency and reliability.

The SSPF filter press operates by using a mechanical transmission system to drive the hydraulic cylinder, which positions and locks the filter plates. Once locked, the hydraulic cylinder presses the filter plates tightly together, forming sealed filter chambers. Material is pumped into these chambers under pressure, enabling solid-liquid separation through the filter medium. The filtrate is discharged through the filter plate's water holes, while the solid material is retained in the chambers. After filtration, the system can perform additional processes such as high-pressure diaphragm squeezing, washing, and drying, depending on process requirements. The hydraulic cylinder then retracts, unlocking the plates for filter cake removal and cleaning, readying the system for the next cycle.

Product Application:

The SSPF filter press is widely used across industries, including:

Metallurgy

Mining

Chemical processing

Paper manufacturing

Food production

Pharmaceuticals

Environmental protection

Product Parameters:

Model filtration area(m2) | amount of filter | volume of filter chamber | Dimensions | Weight (T) | Hydraulic power | specificationsof filter plate mm |

SSPF 40 | 13 | 0.7 | 6.8×3.9×6.1 | 25 | 18.5 | 1500×1500 |

SSPF 60 | 19 | 1.1 | 8.0×3.9×6.1 | 28 | ||

SSPF 80 | 25 | 1.5 | 9.2×3.9×6.1 | 35 | 30 | |

SSPF 100 | 31 | 1.8 | 10.4×3.9×6.1 | 38 | ||

SSPF 120 | 37 | 2.2 | 11.5×3.9×6.1 | 41 | ||

SSPF 140 | 43 | 2.6 | 12.7×3.9×6.1 | 44 | ||

SSPF 160 | 49 | 2.9 | 13.9×3.9×6.1 | 47 | ||

SSPF 180 | 55 | 3.3 | 15.0×3.9×6.1 | 50 | ||

SSPF 200 | 61 | 3.7 | 16.2×3.9×6.1 | 53 | ||

SSPF 220 | 67 | 4.0 | 17.4×3.9×6.1 | 56 | ||

SSPF 240 | 73 | 4.4 | 18.5×3.9×6.1 | 59 |

Product Advantages:

Low Moisture Content: Achieves final material moisture levels as low as 6%, with economic moisture content below 10% for fine tailings in copper, lead, zinc, silver, antimony, molybdenum, phosphorus, and gold processing.

High Production Capacity: Processes up to 10,000 tons of dry slag daily, offering 5-10 times the capacity of traditional chamber or plate-and-frame filters, significantly reducing land and infrastructure costs.

Durable Construction: Key components, including the thrust plate, pressure plate, main beam, and cross beam, are guaranteed against breakage for 5 years.

Adaptability: Proven performance in challenging conditions, such as high altitudes (4,700m), low concentrations (15% feed), and fine particles (-400 mesh accounting for 95%).

Smart Control: PLC and touchscreen interface enable fully automated operation, reducing labor intensity and ensuring consistent performance.

Efficient Design: Features include a hydraulic jacking device for quick plate opening/closing, high-pressure diaphragm squeezing for lower cake moisture, a filter cake vibrating device for easy detachment, and an automatic cloth cleaning system for enhanced efficiency.

Hydraulic jacking device can realize the mechanical working which make the filter plate group quickly opened and closed, hydraulic cylinder short stroke compressed, greatly reduce the hydraulic pressure.After automatic high pressure diaphragm press cake, cake moisture can be lower .Filter cake vibrating device makes the cake more easy detached from filter cloth.Automatic overturning discharge device ensures the filter cake and filtrate without any interference.High pressure automatic cloth cleaning device ensure the filter cloth regeneration high automatic safe and reliable, filter cloth replacement is convenient, high work efficiency.

Service Support

Whole Technological Design: Toncin provides customized solutions based on laboratory tests, semi-industrial trials, and theoretical analysis to address specific customer needs.

Project Construction: Offers end-to-end project management, including design, procurement, construction, and trials, ensuring quality, safety, and cost efficiency.

After-Sales Support:

12-hour response time for technical issues.

On-site support within 72 hours for domestic customers.

24/7 service availability during the warranty period.

The SSPF horizontal smart filter press is a reliable, high-performance solution for solid-liquid separation, combining advanced technology, robust construction, and exceptional service to meet the demands of modern industrial applications.

SSPF Customized Horizontal Smart Filter Press for Solid-Liquid Separation in Mining Processing

The SSPF smart row plate filter press is a state-of-the-art solution designed for efficient solid-liquid separation in mining and industrial processing. This advanced equipment integrates an electrical control system, hydraulic control system, and a robust main engine to deliver high-performance filtration and dehydration. Its fast opening and closing mechanism, combined with intelligent automation, ensures optimal operational efficiency and reliability.

The SSPF filter press operates by using a mechanical transmission system to drive the hydraulic cylinder, which positions and locks the filter plates. Once locked, the hydraulic cylinder presses the filter plates tightly together, forming sealed filter chambers. Material is pumped into these chambers under pressure, enabling solid-liquid separation through the filter medium. The filtrate is discharged through the filter plate's water holes, while the solid material is retained in the chambers. After filtration, the system can perform additional processes such as high-pressure diaphragm squeezing, washing, and drying, depending on process requirements. The hydraulic cylinder then retracts, unlocking the plates for filter cake removal and cleaning, readying the system for the next cycle.

Product Application:

The SSPF filter press is widely used across industries, including:

Metallurgy

Mining

Chemical processing

Paper manufacturing

Food production

Pharmaceuticals

Environmental protection

Product Parameters:

Model filtration area(m2) | amount of filter | volume of filter chamber | Dimensions | Weight (T) | Hydraulic power | specificationsof filter plate mm |

SSPF 40 | 13 | 0.7 | 6.8×3.9×6.1 | 25 | 18.5 | 1500×1500 |

SSPF 60 | 19 | 1.1 | 8.0×3.9×6.1 | 28 | ||

SSPF 80 | 25 | 1.5 | 9.2×3.9×6.1 | 35 | 30 | |

SSPF 100 | 31 | 1.8 | 10.4×3.9×6.1 | 38 | ||

SSPF 120 | 37 | 2.2 | 11.5×3.9×6.1 | 41 | ||

SSPF 140 | 43 | 2.6 | 12.7×3.9×6.1 | 44 | ||

SSPF 160 | 49 | 2.9 | 13.9×3.9×6.1 | 47 | ||

SSPF 180 | 55 | 3.3 | 15.0×3.9×6.1 | 50 | ||

SSPF 200 | 61 | 3.7 | 16.2×3.9×6.1 | 53 | ||

SSPF 220 | 67 | 4.0 | 17.4×3.9×6.1 | 56 | ||

SSPF 240 | 73 | 4.4 | 18.5×3.9×6.1 | 59 |

Product Advantages:

Low Moisture Content: Achieves final material moisture levels as low as 6%, with economic moisture content below 10% for fine tailings in copper, lead, zinc, silver, antimony, molybdenum, phosphorus, and gold processing.

High Production Capacity: Processes up to 10,000 tons of dry slag daily, offering 5-10 times the capacity of traditional chamber or plate-and-frame filters, significantly reducing land and infrastructure costs.

Durable Construction: Key components, including the thrust plate, pressure plate, main beam, and cross beam, are guaranteed against breakage for 5 years.

Adaptability: Proven performance in challenging conditions, such as high altitudes (4,700m), low concentrations (15% feed), and fine particles (-400 mesh accounting for 95%).

Smart Control: PLC and touchscreen interface enable fully automated operation, reducing labor intensity and ensuring consistent performance.

Efficient Design: Features include a hydraulic jacking device for quick plate opening/closing, high-pressure diaphragm squeezing for lower cake moisture, a filter cake vibrating device for easy detachment, and an automatic cloth cleaning system for enhanced efficiency.

Hydraulic jacking device can realize the mechanical working which make the filter plate group quickly opened and closed, hydraulic cylinder short stroke compressed, greatly reduce the hydraulic pressure.After automatic high pressure diaphragm press cake, cake moisture can be lower .Filter cake vibrating device makes the cake more easy detached from filter cloth.Automatic overturning discharge device ensures the filter cake and filtrate without any interference.High pressure automatic cloth cleaning device ensure the filter cloth regeneration high automatic safe and reliable, filter cloth replacement is convenient, high work efficiency.

Service Support

Whole Technological Design: Toncin provides customized solutions based on laboratory tests, semi-industrial trials, and theoretical analysis to address specific customer needs.

Project Construction: Offers end-to-end project management, including design, procurement, construction, and trials, ensuring quality, safety, and cost efficiency.

After-Sales Support:

12-hour response time for technical issues.

On-site support within 72 hours for domestic customers.

24/7 service availability during the warranty period.

The SSPF horizontal smart filter press is a reliable, high-performance solution for solid-liquid separation, combining advanced technology, robust construction, and exceptional service to meet the demands of modern industrial applications.