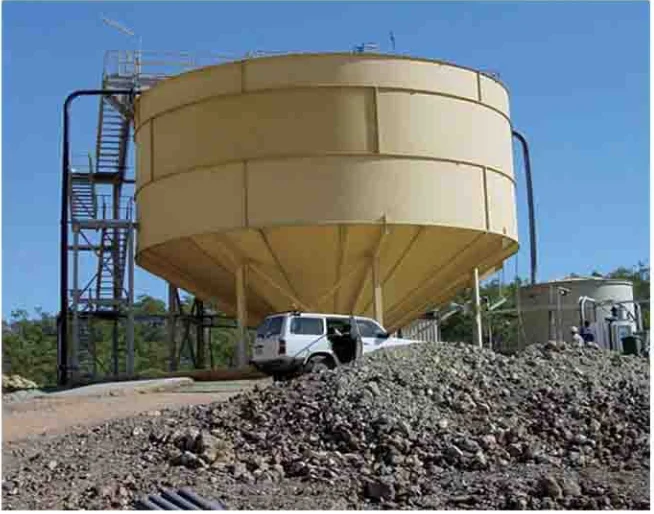

SGN Deep Cone Paste Thickener is mainly composed of deep taper, feeding device, stirring device, control box, drug delivery device and automatic control system. Slurry first enters the deaeration tank for processing, and then enters the swirling feeding tank. The pulp after flocculated in the feeding tank enters the dense sediment layer. By the reflocculation, filtration, and compression of the dense sediment layer, the clarified overflow water is discharged from the overflow weir and the high concentration underflow is discharged from the bottom cone.

| Availability: | |

|---|---|

| Quantity: | |

SGN Deep Cone Thickener

Toncin

Product Introduction:

SGN-()

S – Deep cone

G – High rate

N – Thickener

()– diameter of sediment tank (M)

SGN Deep Cone Paste Thickener is mainly composed of deep taper, feeding device, stirring device, control box, drug delivery device and automatic control system. Slurry first enters the deaeration tank for processing, and then enters the swirling feeding tank. The pulp after flocculated in the feeding tank enters the dense sediment layer. By the reflocculation, filtration, and compression of the dense sediment layer, the clarified overflow water is discharged from the overflow weir and the high concentration underflow is discharged from the bottom cone.

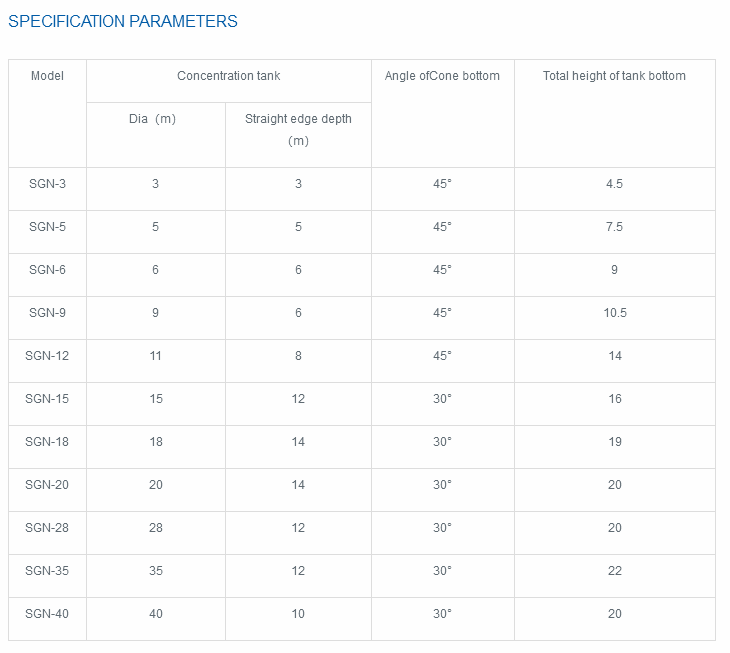

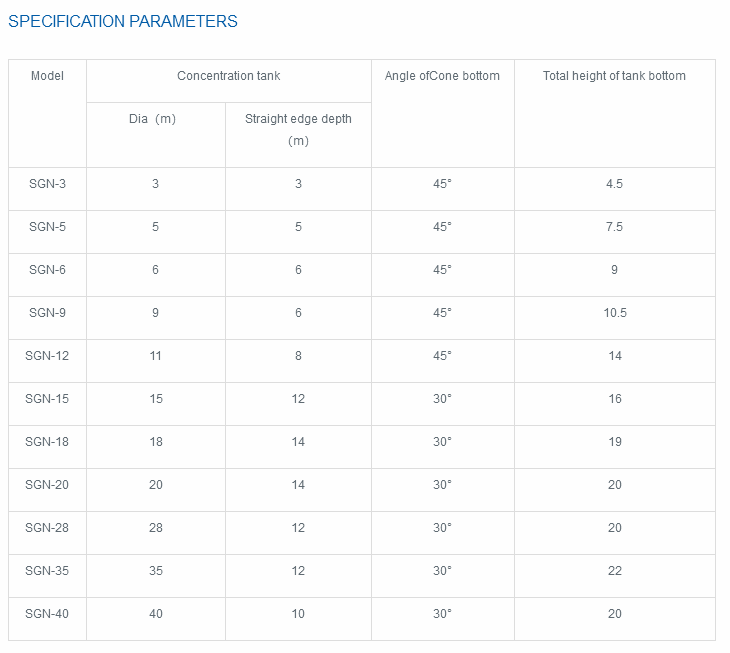

Product Specifications:

Main features:

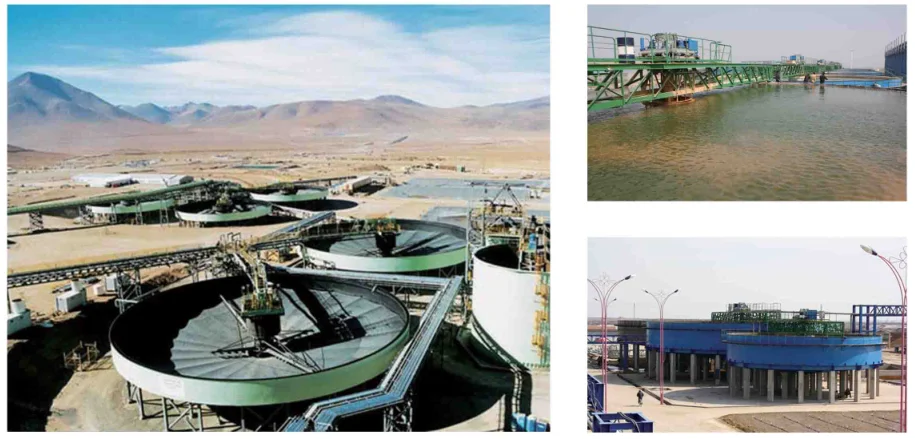

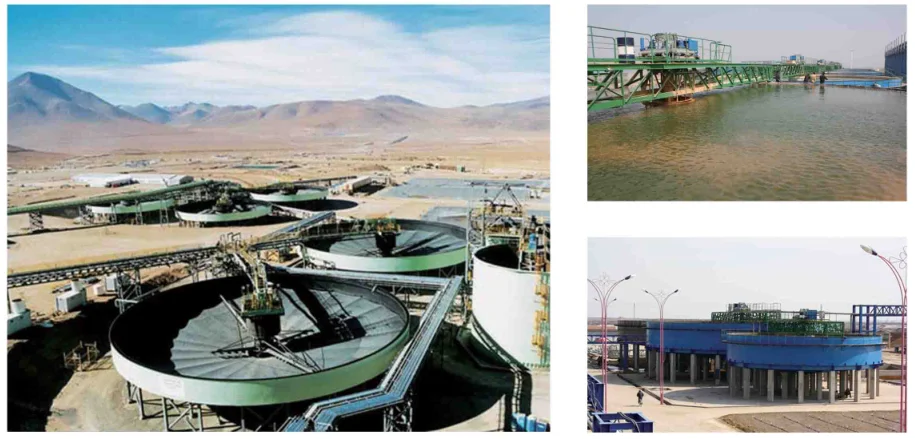

Highly Efficient Customized SGN Paste Thickener for Mining Processing Plants

Boasting substantial processing capacity and an outstanding concentration effect, this thickener achieves a remarkable tailings concentration of 40-70% in metal mines, with suspended substances in the overflow measuring less than 500×10-6.

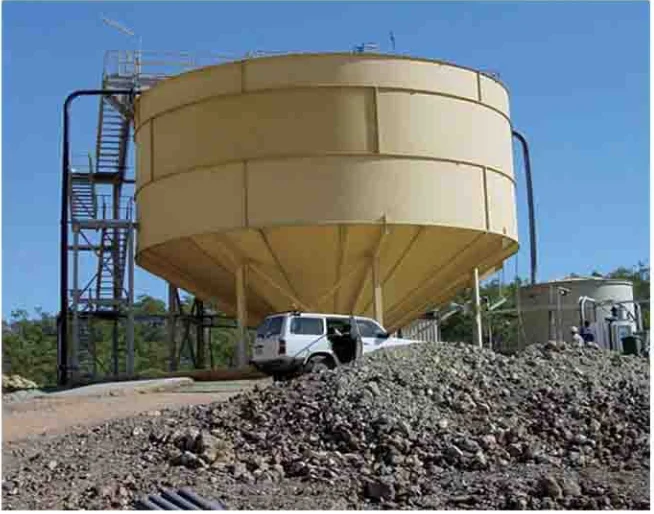

Distinguished by its imposing stature and an aspect ratio typically ranging from 1.2-2, this thickener stands out from conventional models in mineral processing plants.

It demands minimal floor space, involves a modest investment, boasts low power consumption, operating costs, and offers convenient management.

The option to incorporate plastic sloping plates enhances the effective sediment area and concentration efficiency.

Equipped with a water lever system designed to disrupt the solid-liquid equilibrium, this thickener significantly improves underflow concentration.

Model:

Product Advantages:

Unique high aspect ratio in appearance compared to common thickeners in concentration plants.

Small floor area, low investment, power-saving, low operating costs, and easy management.

Option to add plastic sloping plates inside the machine to enhance effective precipitation area and concentration efficiency.

Service Support:

Whole Technological Design

Toncin establishes reasonable plans and selections through systematic laboratory tests, semi-industrialization tests, and theoretical analysis calculations, addressing specific customer challenges. Specific parameters are determined through laboratory and semi-industrial tests.

Project Construction

Toncin provides integrated project services, managing project quality, schedule, safety, cost, procurement, information files, organization, and coordination according to customer contractual documents. Toncin handles the design, procurement, construction, and trials for the entire process or specific stages of the construction project, assuming full liability for quality, safety, duration, and cost.

Response Time and After-sales Services

In case of any defects during the warranty period, our company commits to responding within 12 hours and reaching the domestic scene within 72 hours. With a rigorous and efficient service architecture, Toncin offers diverse and flexible service and response means, ensuring 24/7 response service during the warranty period.

Product Introduction:

SGN-()

S – Deep cone

G – High rate

N – Thickener

()– diameter of sediment tank (M)

SGN Deep Cone Paste Thickener is mainly composed of deep taper, feeding device, stirring device, control box, drug delivery device and automatic control system. Slurry first enters the deaeration tank for processing, and then enters the swirling feeding tank. The pulp after flocculated in the feeding tank enters the dense sediment layer. By the reflocculation, filtration, and compression of the dense sediment layer, the clarified overflow water is discharged from the overflow weir and the high concentration underflow is discharged from the bottom cone.

Product Specifications:

Main features:

Highly Efficient Customized SGN Paste Thickener for Mining Processing Plants

Boasting substantial processing capacity and an outstanding concentration effect, this thickener achieves a remarkable tailings concentration of 40-70% in metal mines, with suspended substances in the overflow measuring less than 500×10-6.

Distinguished by its imposing stature and an aspect ratio typically ranging from 1.2-2, this thickener stands out from conventional models in mineral processing plants.

It demands minimal floor space, involves a modest investment, boasts low power consumption, operating costs, and offers convenient management.

The option to incorporate plastic sloping plates enhances the effective sediment area and concentration efficiency.

Equipped with a water lever system designed to disrupt the solid-liquid equilibrium, this thickener significantly improves underflow concentration.

Model:

Product Advantages:

Unique high aspect ratio in appearance compared to common thickeners in concentration plants.

Small floor area, low investment, power-saving, low operating costs, and easy management.

Option to add plastic sloping plates inside the machine to enhance effective precipitation area and concentration efficiency.

Service Support:

Whole Technological Design

Toncin establishes reasonable plans and selections through systematic laboratory tests, semi-industrialization tests, and theoretical analysis calculations, addressing specific customer challenges. Specific parameters are determined through laboratory and semi-industrial tests.

Project Construction

Toncin provides integrated project services, managing project quality, schedule, safety, cost, procurement, information files, organization, and coordination according to customer contractual documents. Toncin handles the design, procurement, construction, and trials for the entire process or specific stages of the construction project, assuming full liability for quality, safety, duration, and cost.

Response Time and After-sales Services

In case of any defects during the warranty period, our company commits to responding within 12 hours and reaching the domestic scene within 72 hours. With a rigorous and efficient service architecture, Toncin offers diverse and flexible service and response means, ensuring 24/7 response service during the warranty period.