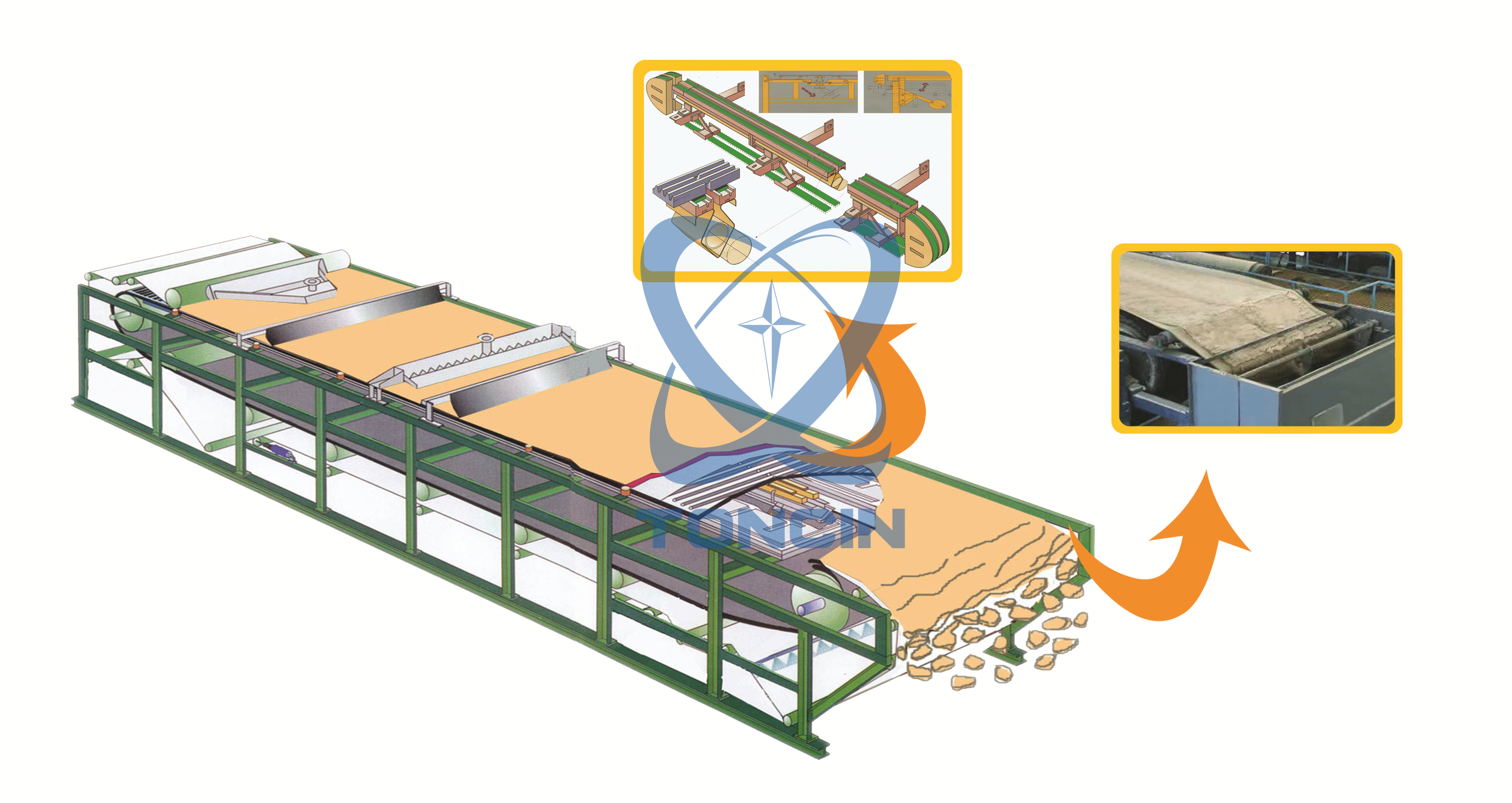

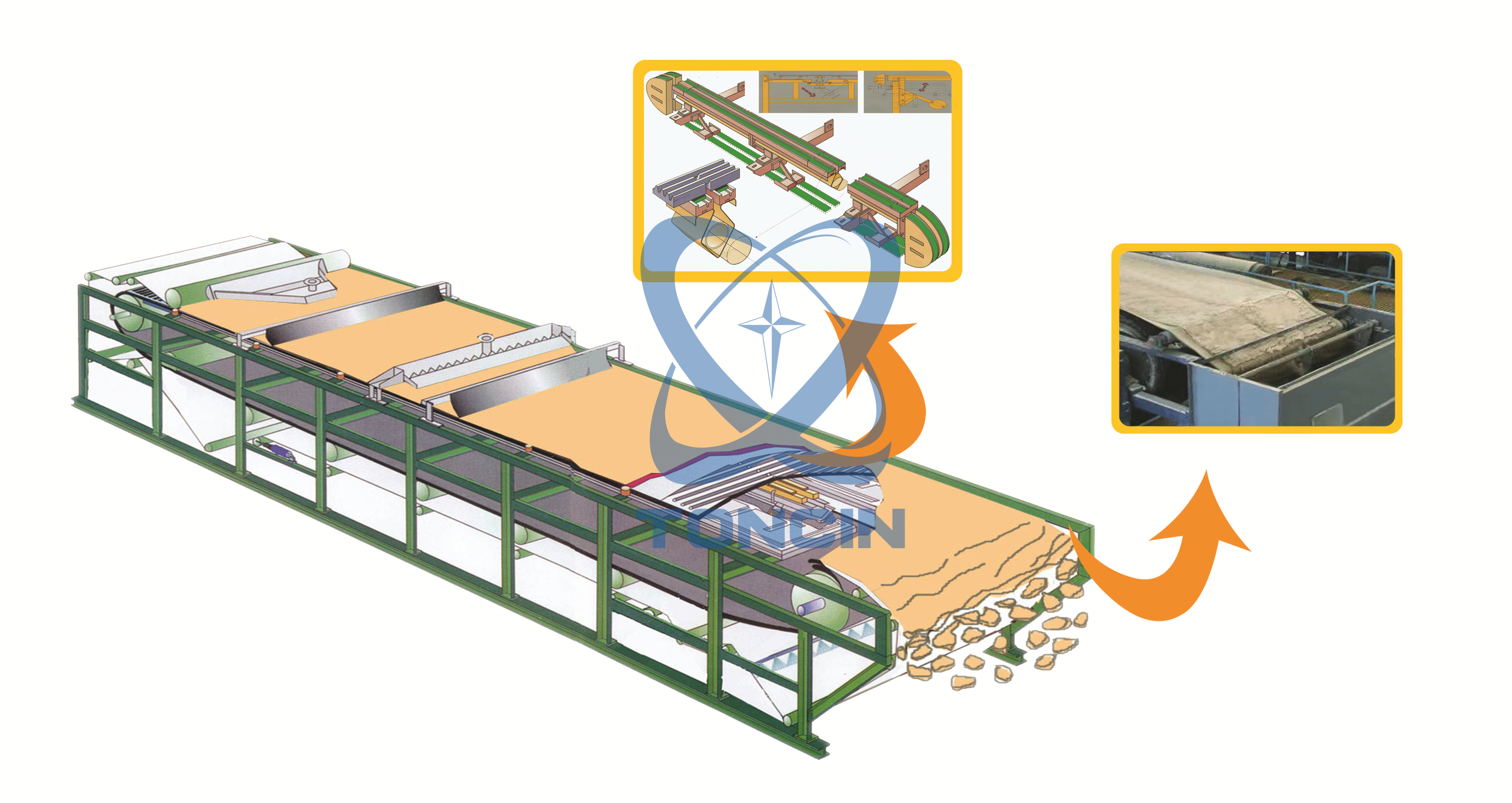

The DU rubber belt vacuum filter operates by utilizing vacuum negative pressure to achieve solid-liquid separation. Its filtration section is horizontally arranged, allowing for continuous processes such as filtration, washing, blotting, and filter cloth regeneration. This equipment boasts high filtration efficiency, a large production capacity, effective washing capabilities, a low water content in the filter cake, flexible operation, and minimal maintenance costs.

| Availability: | |

|---|---|

| Quantity: | |

DU Belt Filter

Toncin

DU RUBBER BELT VACCUM FILTE

Description

The DU rubber belt vacuum filter operates by utilizing vacuum negative pressure to achieve solid-liquid separation. Its filtration section is horizontally arranged, allowing for continuous processes such as filtration, washing, blotting, and filter cloth regeneration. This equipment boasts high filtration efficiency, a large production capacity, effective washing capabilities, a low water content in the filter cake, flexible operation, and minimal maintenance costs.

Application for Toncin's BELT FILTER

The filtration section of the vacuum belt filter is arranged along the horizontal length direction, and can continuously and automatically complete process operations such as filtration, cake washing, slag unloading, and filter cloth regeneration. The mother liquor and cake washing liquid can be collected in sections. It has the advantages of high filtration efficiency, large production capacity, good washing efficiency, low moisture content in filter cake, flexible operation, and simple maintenance. The equipment has been improved and perfected by our company for many years, and the technical performance and quality of the products have reached the international advanced level. It has been widely used in solid-liquid separation in metallurgy, mining, chemical industry, papermaking, food, pharmaceuticals, coal washing, environmental protection and other fields, especially in gypsum dewatering (FGD) in flue gas desulfurization.

Technical Features

The overall modular design allows for flexible assembly, making it easy to transport and install.

High degree of automation; Cutting, filtering, washing, drying, unloading, and cleaning of filter cloth are all continuously automated, which improves production efficiency, reduces operating costs, greatly reduces labor intensity for workers, and improves the working environment.

Fast filtering speed; The material passes through the sedimentation zone, with large particles in the bottom layer and small particles in the upper layer. The filter cake structure is reasonable, and the filtrate has low permeability resistance, allowing for rapid thin-layer filtration.

Convenient filtration process; Filter cake thickness and washing water volume. The reverse washing stage, vacuum degree, and filter cloth speed can be adjusted arbitrarily to achieve the best filtration effect.

Good washing effect; It can achieve multi-stage parallel or countercurrent washing, with uniform and thorough washing. The mother liquor and washing solution can be collected and reused separately according to process requirements.

The control system applies DCS technology, which can achieve on-site and remote automatic control.

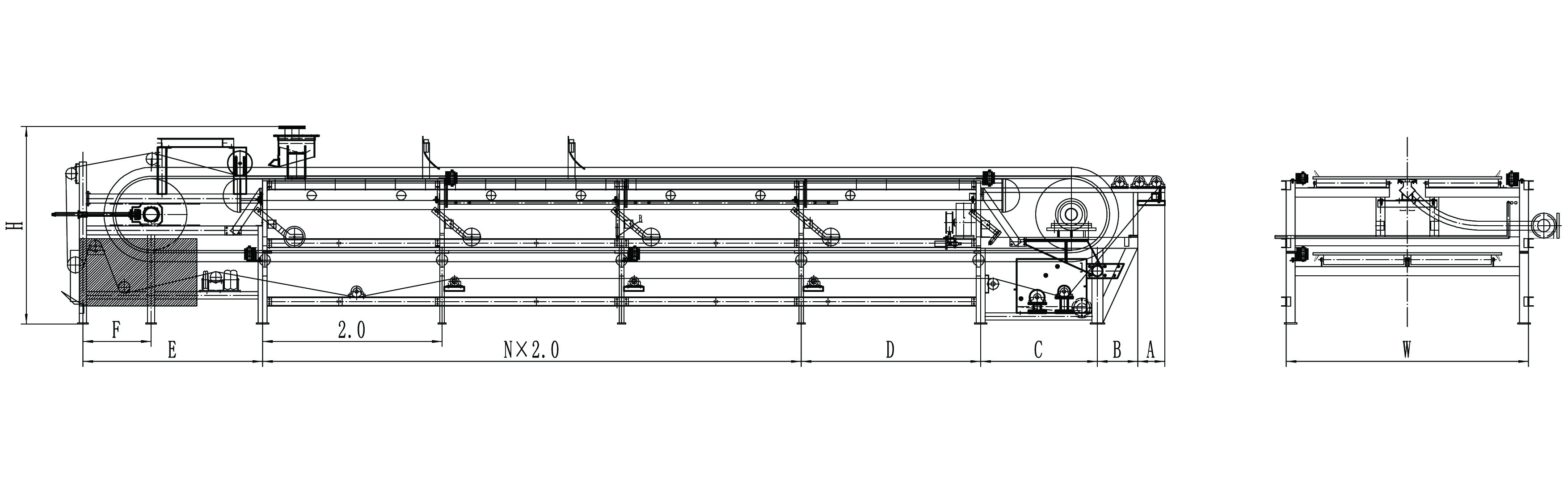

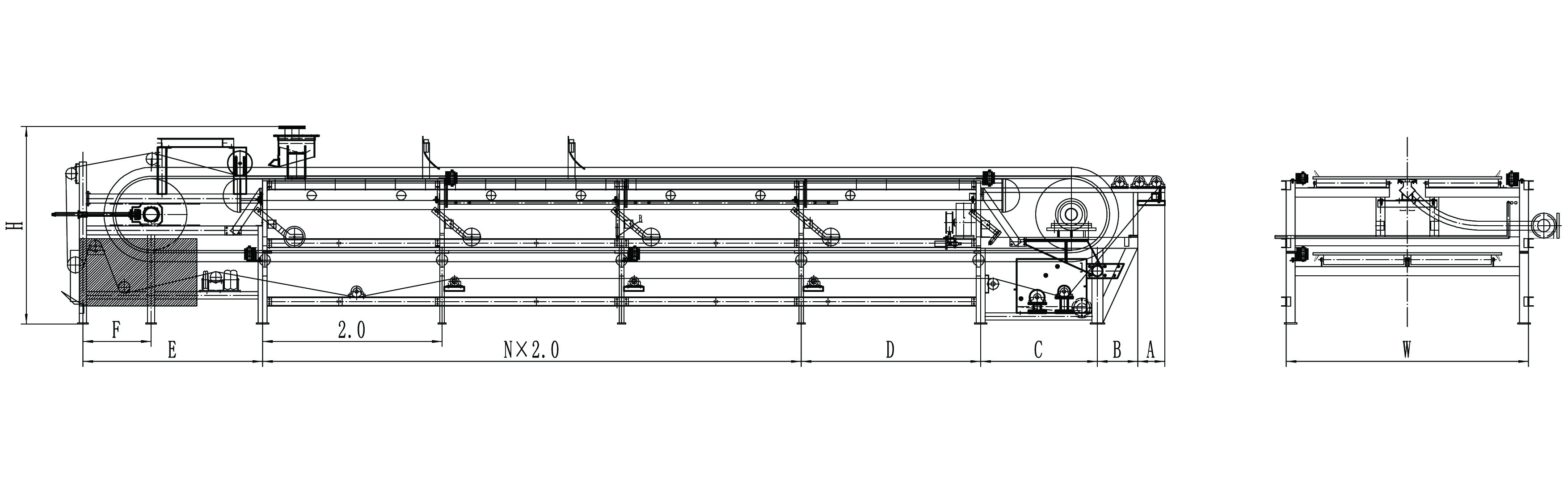

Outline Size Drawing

Product Specification

Filtration Area (m2) | Filtration width(mm) | Filtration Length (m ) | Weight (T) | Outline Size L×W×H (m) | Filtration Area (m2) | Filtration width(mm) | Filtration Length(m ) | Weight (T) | Outline Size L×W×H (m) |

DU-2 | 500 | 4 | 3.0 | 7.82×2×2 | DU-25 | 2500 | 10 | 22 | 14.5×4.8×2.2 |

DU-2.5 | 5 | 3.2 | 8.82×2×2 | DU-30 | 12 | 25.3 | 16.5×4.8×2.2 | ||

DU-3 | 6 | 3.4 | 9.9×2×2 | DU-35 | 14 | 27.4 | 18.5×4.8×2.2 | ||

DU-5 | 10 | 3.8 | 14.0×2.2×2 | DU-40 | 16 | 29.5 | 21.5×4.8×2.4 | ||

DU-4.8 | 800 | 6 | 5.0 | 10.05×2.5×2 | DU-45 | 18 | 31.6 | 23.5×4.8×2.4 | |

DU-6.4 | 8 | 5.5 | 12.05×2.5×2 | DU-50 | 20 | 38.6 | 25.6×4.8×2.4 | ||

DU-8 | 10 | 6.0 | 14.10×2.6×2 | DU-33.6 | 2800 | 12 | 20.5 | 17.6×5.0×2.5 | |

DU-9.6 | 12 | 7.0 | 16.25×2.6×2 | DU-39.2 | 14 | 24.1 | 19.6×5.0×2.5 | ||

DU-5 | 1000 | 5 | 5.3 | 8.87×2.6×20 | DU-36 | 3000 | 12 | 22 | 17.6×5.5×2.8 |

DU-6 | 6 | 5.8 | 10.5×2.6×2 | DU-42 | 14 | 24 | 19.6×5.5×2.8 | ||

DU-8 | 8 | 6.3 | 12.5×2.8×2 | DU-48 | 16 | 28 | 21.6×5.5×2.8 | ||

DU-10 | 10 | 6.8 | 14.5×2.8×2 | DU-54 | 18 | 30.6 | 23.6×5.5×2.8 | ||

DU-12 | 12 | 7.3 | 16.5×2.8×2 | DU-60 | 20 | 35.2 | 25.6×5.5×2.8 | ||

DU-14 | 14 | 7.8 | 18.5×2.8×2 | DU-44.8 | 3200 | 14 | 35.3 | 19.5×5.7×3.1 | |

DU-7.8 | 1300 | 6 | 7.2 | 10.4×3.15×2 | DU-48 | 15 | 36.2 | 20.5×5.7×3.1 | |

DU-10.4 | 8 | 8.3 | 12.4×3.15×2 | DU-51.2 | 16 | 37.7 | 21.5×5.7×3.1 | ||

DU-13 | 10 | 9 | 14.4×3.15×2 | DU-57.6 | 18 | 40.1 | 23.5×5.7×3.1 | ||

DU-15.6 | 12 | 10.5 | 16.4×3.15×2 | DU-64 | 20 | 42.5 | 25.5×5.7×3.1 | ||

DU-18.2 | 14 | 11.5 | 18.4×3.15×2 | DU-72 | 22.5 | 52.4 | 28.5×5.7×3.1 | ||

DU-20.8 | 16 | 12.5 | 20.4×3.15×2 | DU-72 | 4000 | 18 | 56.2 | 24.0×7.1×3.3 | |

DU-14.4 | 1800 | 8 | 12.7 | 12.6×4×2.2 | DU-80 | 20 | 58.8 | 26.0×7.1×3.3 | |

DU-18 | 10 | 13.7 | 14.6×4×2.2 | DU-88 | 22 | 66.6 | 28.0×7.1×3.3 | ||

DU-21.6 | 12 | 15.3 | 16.6×4×2.2 | DU-96 | 24 | 69.4 | 30.0×7.1×3.3 | ||

DU-25.2 | 14 | 16.6 | 18.6×4×2.2 | DU-104 | 26 | 72.2 | 32.0×7.1×3.3 | ||

DU-28.8 | 16 | 17.9 | 20.6×4×2.2 | DU-90 | 4500 | 20 | 72 | 26.5×7.5×3.6 | |

DU-16 | 2000 | 8 | 14.2 | 12.7×4.2×2.2 | DU-99 | 22 | 75.2 | 28.5×7.5×3.6 | |

DU-20 | 10 | 15.4 | 14.7×4.2×2.2 | DU-108 | 24 | 78.4 | 30.5×7.5×3.6 | ||

DU-24 | 12 | 17.2 | 16.7×4.2×2.2 | DU-117 | 26 | 81.6 | 32.5×7.5×3.6 | ||

DU-28 | 14 | 18.7 | 18.7×4.2×2.2 | DU-126 | 28 | 84.8 | 34.5×7.5×3.6 | ||

DU-32 | 16 | 20.2 | 20.7×4.2×2.2 | DU-135 | 30 | 88 | 36.5×7.5×3.6 | ||

DU-36 | 18 | 21.7 | 22.7×4.2×2.2 | DU-144 | 32 | 93 | 38.5×7.5×3.6 |

Product Introduction:

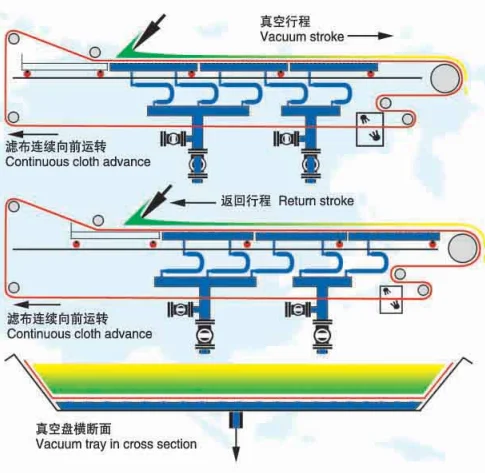

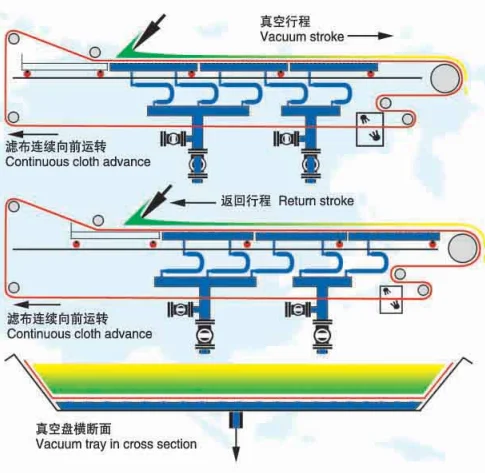

The rubber belt vacuum filter is an efficient filtration solid-liquid separation equipment independently developed based on the introduction of similar foreign product technology. The device adopts a fixed vacuum box, and the tape slides on the vacuum box, forming a motion sealed structure between the vacuum box and the tape. The device achieves solid-liquid separation with vacuum negative pressure as the driving force. It uses filter cloth as the filtering medium and relies on negative pressure to achieve solid-liquid separation. The device has a simple structure, low production and operation costs, and is easy to maintain and operate. The production process is fully automated, and the operating speed, feeding speed, and washing water volume can be freely adjusted according to production needs. After years of development, the tape vacuum filter has reached the international advanced technology level and is widely used in industries such as power environmental protection, mining, chemical industry, metallurgy, papermaking, food, pharmaceuticals, and coal.

Technical Characteriatics:

The process of the feeding, filtering, washing, discharging and the regenerating can be achieved efficiently and automatically.

It can wash slurry by the methods of multistage current or countercurrent. The filtration liquor and the washing liquor can be collected separately.

It can filter a thin layer cake quickly for the hard filtration and the high viscosity slurry.

It is flexible to assemble equipment because of the modular structure.

It is convenient to do the remote and spot control for the PLC.

Washing device

Adopts the craft water to spray the filtration cloth and matched with the vacuum sucker seal box. Therefore, it can guarantee the jobsite cleanly. The nozzle made by American sprayer company can guarantee the washing effect well.

Material spraying craft

Adopts the countercurrent washing device or the spray washing device. According to the character of the material and the craft of the requirement, it can choose the two methods of the current washing or the countercurrent washing and make the washing more thoroughly.

Deviation-rectifying mechanism

Under the working of the cylinder or the air-bag, achieve correcting the deviation of the cloth and make sure the cloth run correctly.

Control system

Adopts remote control and scene alternately control, facilitated the operation work, is advantageous for implementing nobody operation.

Product Advantages:

It can continuously auto-complete feeding, filtering, washing, slag removal and filter cloth regeneration in high automation.

It can multi-levelly wash materials in advection or countercurrent, and the filtrate (mother liquid) and washing liquid can be collected in separate.

For materials with poor filterability and high viscosity, it can realize thin layer fast filtration, and it is in modular design, flexible combination and strong adaptability.

It adopts PLC control, facilitating remote control and centralized control.

It adopts serpentine correction, which solves the deviation and buckling of the filter cloth.

Product Specifications:

Width of filter tray | 0.625-2.0(mm) | 2.5-3.0(m) | 0.625m | 1.25m | 1.6m | 2.0m | 2.5m | 3.0m | ||||||||

Filtering length(mm) | N | L | N | L | Filtering area(m2) | weight(kg) | Filtering area(m2) | weight(kg) | Filtering area(m2) | weight(kg) | Filtering area(m2) | weight(kg) | Filtering area(m2) | weight(kg) | Filtering area(m2) | weight(kg) |

3000 | 0 | 6125 | 1 | 6150 | 1.9 | 2400 | 3.8 | 2850 | 4.8 | 3100 | 6.0 | 3400 | 7.5 | 3800 | 9 | 4200 |

4500 | 1 | 7625 | 2 | 7650 | 2.8 | 2600 | 5.6 | 3100 | 7.2 | 3400 | 9.0 | 3750 | 11.3 | 4200 | 13.5 | 4650 |

6000 | 2 | 9125 | 3 | 9150 | 3.8 | 2800 | 7.5 | 3350 | 9.6 | 3700 | 12.0 | 4100 | 15 | 4600 | 18 | 5100 |

7500 | 3 | 10625 | 4 | 10650 | 4.7 | 3000 | 9.4 | 3600 | 12 | 4000 | 15.0 | 4450 | 18.8 | 5000 | 22.5 | 5550 |

9000 | 4 | 12125 | 5 | 12150 | 5.6 | 3200 | 11.3 | 3850 | 14.4 | 4300 | 18.0 | 4800 | 22.5 | 5400 | 27 | 6000 |

10500 | 5 | 13625 | 6 | 13650 | 6.6 | 3400 | 13.1 | 4100 | 16.8 | 4600 | 21.0 | 5150 | 26.3 | 5800 | 31.5 | 6450 |

12000 | 6 | 15125 | 7 | 15150 | 7.5 | 3600 | 15.0 | 4350 | 19.2 | 4900 | 24.0 | 5500 | 30 | 6200 | 36 | 6900 |

13500 | 7 | 16625 | 8 | 16650 | 8.4 | 3800 | 16.9 | 4600 | 21.6 | 5200 | 27.0 | 5850 | 33.8 | 6600 | 40.5 | 7350 |

A | 600 | 600 | 600 | 600 | 500 | 500 | ||||||||||

B | 2400 | 2400 | 2400 | 2400 | 2000 | 2000 | ||||||||||

C | 3000 | 3000 | 3000 | 3000 | 2000 | 2000 | ||||||||||

D | 1550 | 1550 | 1650 | 1650 | 1700 | 1700 | ||||||||||

E | 1100 | 1800 | 2200 | 2600 | 3150 | 3650 | ||||||||||

Fmax | 2100 | 2800 | 3200 | 3600 | 4150 | 4650 | ||||||||||

G | 973.5 | 973.5 | 973.5 | 973.5 | 1028.5 | 1028.5 | ||||||||||

Hmax | 1348.5 | 1348.5 | 1348.5 | 1348.5 | 1403.5 | 1403.5 | ||||||||||

I | 585 | 585 | 585 | 585 | 612 | 612 | ||||||||||

J | 1104 | 1104 | 1104 | 1104 | 1163 | 1163 | ||||||||||

K | 2736 | 2736 | 3136 | 3536 | 4146 | 4646 | ||||||||||

M | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | ||||||||||

R | 1250 | 1250 | 1250 | 1250 | 1350 | 1350 | ||||||||||

S | 1400 | 2100 | 2500 | 2900 | 3450 | 3950 | ||||||||||

T | 1670 | 1670 | 1770 | 1770 | 1870 | 1870 | ||||||||||

Service Support

Whole Technological Design

Toncin determines reasonable plans and selections by conducting more systematic laboratory tests, semi-industrialization tests and theoretical analysis calculations and adopting appropriate methods in light of the actual problems faced by customers. And it determines specific parameters through laboratory tests and semi-industrial tests.

Project Construction

Toncin can provide customers with integrated project services for its perfect project management system and experienced high-quality team and can also provide customers with its best services in achieving the ultimate project goal by carrying out the management work on the project quality, schedule, safety, cost, procurement, information files, organization and coordination etc. according to customer’s contractual documents. Toncin contracts the design, procurement, construction and trials etc. for the entire process or some certain stages of the construction project according to the contract and takes full liability for the quality, safety, duration and cost etc. of the contracted project.

Response Time and After-sales Services

If any failure due to a defect has occurred during the warranty period, our company has given the following response and promise: to respond within 12 hours and rush to the domestic scene within 72 hours. With a rigorous and efficient service architecture, diverse and flexible service and response means, Toncin is capable of providing response service up to 7* 24 hours to ensure that users can get help at any time during the warranty period.

DU RUBBER BELT VACCUM FILTE

Description

The DU rubber belt vacuum filter operates by utilizing vacuum negative pressure to achieve solid-liquid separation. Its filtration section is horizontally arranged, allowing for continuous processes such as filtration, washing, blotting, and filter cloth regeneration. This equipment boasts high filtration efficiency, a large production capacity, effective washing capabilities, a low water content in the filter cake, flexible operation, and minimal maintenance costs.

Application for Toncin's BELT FILTER

The filtration section of the vacuum belt filter is arranged along the horizontal length direction, and can continuously and automatically complete process operations such as filtration, cake washing, slag unloading, and filter cloth regeneration. The mother liquor and cake washing liquid can be collected in sections. It has the advantages of high filtration efficiency, large production capacity, good washing efficiency, low moisture content in filter cake, flexible operation, and simple maintenance. The equipment has been improved and perfected by our company for many years, and the technical performance and quality of the products have reached the international advanced level. It has been widely used in solid-liquid separation in metallurgy, mining, chemical industry, papermaking, food, pharmaceuticals, coal washing, environmental protection and other fields, especially in gypsum dewatering (FGD) in flue gas desulfurization.

Technical Features

The overall modular design allows for flexible assembly, making it easy to transport and install.

High degree of automation; Cutting, filtering, washing, drying, unloading, and cleaning of filter cloth are all continuously automated, which improves production efficiency, reduces operating costs, greatly reduces labor intensity for workers, and improves the working environment.

Fast filtering speed; The material passes through the sedimentation zone, with large particles in the bottom layer and small particles in the upper layer. The filter cake structure is reasonable, and the filtrate has low permeability resistance, allowing for rapid thin-layer filtration.

Convenient filtration process; Filter cake thickness and washing water volume. The reverse washing stage, vacuum degree, and filter cloth speed can be adjusted arbitrarily to achieve the best filtration effect.

Good washing effect; It can achieve multi-stage parallel or countercurrent washing, with uniform and thorough washing. The mother liquor and washing solution can be collected and reused separately according to process requirements.

The control system applies DCS technology, which can achieve on-site and remote automatic control.

Outline Size Drawing

Product Specification

Filtration Area (m2) | Filtration width(mm) | Filtration Length (m ) | Weight (T) | Outline Size L×W×H (m) | Filtration Area (m2) | Filtration width(mm) | Filtration Length(m ) | Weight (T) | Outline Size L×W×H (m) |

DU-2 | 500 | 4 | 3.0 | 7.82×2×2 | DU-25 | 2500 | 10 | 22 | 14.5×4.8×2.2 |

DU-2.5 | 5 | 3.2 | 8.82×2×2 | DU-30 | 12 | 25.3 | 16.5×4.8×2.2 | ||

DU-3 | 6 | 3.4 | 9.9×2×2 | DU-35 | 14 | 27.4 | 18.5×4.8×2.2 | ||

DU-5 | 10 | 3.8 | 14.0×2.2×2 | DU-40 | 16 | 29.5 | 21.5×4.8×2.4 | ||

DU-4.8 | 800 | 6 | 5.0 | 10.05×2.5×2 | DU-45 | 18 | 31.6 | 23.5×4.8×2.4 | |

DU-6.4 | 8 | 5.5 | 12.05×2.5×2 | DU-50 | 20 | 38.6 | 25.6×4.8×2.4 | ||

DU-8 | 10 | 6.0 | 14.10×2.6×2 | DU-33.6 | 2800 | 12 | 20.5 | 17.6×5.0×2.5 | |

DU-9.6 | 12 | 7.0 | 16.25×2.6×2 | DU-39.2 | 14 | 24.1 | 19.6×5.0×2.5 | ||

DU-5 | 1000 | 5 | 5.3 | 8.87×2.6×20 | DU-36 | 3000 | 12 | 22 | 17.6×5.5×2.8 |

DU-6 | 6 | 5.8 | 10.5×2.6×2 | DU-42 | 14 | 24 | 19.6×5.5×2.8 | ||

DU-8 | 8 | 6.3 | 12.5×2.8×2 | DU-48 | 16 | 28 | 21.6×5.5×2.8 | ||

DU-10 | 10 | 6.8 | 14.5×2.8×2 | DU-54 | 18 | 30.6 | 23.6×5.5×2.8 | ||

DU-12 | 12 | 7.3 | 16.5×2.8×2 | DU-60 | 20 | 35.2 | 25.6×5.5×2.8 | ||

DU-14 | 14 | 7.8 | 18.5×2.8×2 | DU-44.8 | 3200 | 14 | 35.3 | 19.5×5.7×3.1 | |

DU-7.8 | 1300 | 6 | 7.2 | 10.4×3.15×2 | DU-48 | 15 | 36.2 | 20.5×5.7×3.1 | |

DU-10.4 | 8 | 8.3 | 12.4×3.15×2 | DU-51.2 | 16 | 37.7 | 21.5×5.7×3.1 | ||

DU-13 | 10 | 9 | 14.4×3.15×2 | DU-57.6 | 18 | 40.1 | 23.5×5.7×3.1 | ||

DU-15.6 | 12 | 10.5 | 16.4×3.15×2 | DU-64 | 20 | 42.5 | 25.5×5.7×3.1 | ||

DU-18.2 | 14 | 11.5 | 18.4×3.15×2 | DU-72 | 22.5 | 52.4 | 28.5×5.7×3.1 | ||

DU-20.8 | 16 | 12.5 | 20.4×3.15×2 | DU-72 | 4000 | 18 | 56.2 | 24.0×7.1×3.3 | |

DU-14.4 | 1800 | 8 | 12.7 | 12.6×4×2.2 | DU-80 | 20 | 58.8 | 26.0×7.1×3.3 | |

DU-18 | 10 | 13.7 | 14.6×4×2.2 | DU-88 | 22 | 66.6 | 28.0×7.1×3.3 | ||

DU-21.6 | 12 | 15.3 | 16.6×4×2.2 | DU-96 | 24 | 69.4 | 30.0×7.1×3.3 | ||

DU-25.2 | 14 | 16.6 | 18.6×4×2.2 | DU-104 | 26 | 72.2 | 32.0×7.1×3.3 | ||

DU-28.8 | 16 | 17.9 | 20.6×4×2.2 | DU-90 | 4500 | 20 | 72 | 26.5×7.5×3.6 | |

DU-16 | 2000 | 8 | 14.2 | 12.7×4.2×2.2 | DU-99 | 22 | 75.2 | 28.5×7.5×3.6 | |

DU-20 | 10 | 15.4 | 14.7×4.2×2.2 | DU-108 | 24 | 78.4 | 30.5×7.5×3.6 | ||

DU-24 | 12 | 17.2 | 16.7×4.2×2.2 | DU-117 | 26 | 81.6 | 32.5×7.5×3.6 | ||

DU-28 | 14 | 18.7 | 18.7×4.2×2.2 | DU-126 | 28 | 84.8 | 34.5×7.5×3.6 | ||

DU-32 | 16 | 20.2 | 20.7×4.2×2.2 | DU-135 | 30 | 88 | 36.5×7.5×3.6 | ||

DU-36 | 18 | 21.7 | 22.7×4.2×2.2 | DU-144 | 32 | 93 | 38.5×7.5×3.6 |

Product Introduction:

The rubber belt vacuum filter is an efficient filtration solid-liquid separation equipment independently developed based on the introduction of similar foreign product technology. The device adopts a fixed vacuum box, and the tape slides on the vacuum box, forming a motion sealed structure between the vacuum box and the tape. The device achieves solid-liquid separation with vacuum negative pressure as the driving force. It uses filter cloth as the filtering medium and relies on negative pressure to achieve solid-liquid separation. The device has a simple structure, low production and operation costs, and is easy to maintain and operate. The production process is fully automated, and the operating speed, feeding speed, and washing water volume can be freely adjusted according to production needs. After years of development, the tape vacuum filter has reached the international advanced technology level and is widely used in industries such as power environmental protection, mining, chemical industry, metallurgy, papermaking, food, pharmaceuticals, and coal.

Technical Characteriatics:

The process of the feeding, filtering, washing, discharging and the regenerating can be achieved efficiently and automatically.

It can wash slurry by the methods of multistage current or countercurrent. The filtration liquor and the washing liquor can be collected separately.

It can filter a thin layer cake quickly for the hard filtration and the high viscosity slurry.

It is flexible to assemble equipment because of the modular structure.

It is convenient to do the remote and spot control for the PLC.

Washing device

Adopts the craft water to spray the filtration cloth and matched with the vacuum sucker seal box. Therefore, it can guarantee the jobsite cleanly. The nozzle made by American sprayer company can guarantee the washing effect well.

Material spraying craft

Adopts the countercurrent washing device or the spray washing device. According to the character of the material and the craft of the requirement, it can choose the two methods of the current washing or the countercurrent washing and make the washing more thoroughly.

Deviation-rectifying mechanism

Under the working of the cylinder or the air-bag, achieve correcting the deviation of the cloth and make sure the cloth run correctly.

Control system

Adopts remote control and scene alternately control, facilitated the operation work, is advantageous for implementing nobody operation.

Product Advantages:

It can continuously auto-complete feeding, filtering, washing, slag removal and filter cloth regeneration in high automation.

It can multi-levelly wash materials in advection or countercurrent, and the filtrate (mother liquid) and washing liquid can be collected in separate.

For materials with poor filterability and high viscosity, it can realize thin layer fast filtration, and it is in modular design, flexible combination and strong adaptability.

It adopts PLC control, facilitating remote control and centralized control.

It adopts serpentine correction, which solves the deviation and buckling of the filter cloth.

Product Specifications:

Width of filter tray | 0.625-2.0(mm) | 2.5-3.0(m) | 0.625m | 1.25m | 1.6m | 2.0m | 2.5m | 3.0m | ||||||||

Filtering length(mm) | N | L | N | L | Filtering area(m2) | weight(kg) | Filtering area(m2) | weight(kg) | Filtering area(m2) | weight(kg) | Filtering area(m2) | weight(kg) | Filtering area(m2) | weight(kg) | Filtering area(m2) | weight(kg) |

3000 | 0 | 6125 | 1 | 6150 | 1.9 | 2400 | 3.8 | 2850 | 4.8 | 3100 | 6.0 | 3400 | 7.5 | 3800 | 9 | 4200 |

4500 | 1 | 7625 | 2 | 7650 | 2.8 | 2600 | 5.6 | 3100 | 7.2 | 3400 | 9.0 | 3750 | 11.3 | 4200 | 13.5 | 4650 |

6000 | 2 | 9125 | 3 | 9150 | 3.8 | 2800 | 7.5 | 3350 | 9.6 | 3700 | 12.0 | 4100 | 15 | 4600 | 18 | 5100 |

7500 | 3 | 10625 | 4 | 10650 | 4.7 | 3000 | 9.4 | 3600 | 12 | 4000 | 15.0 | 4450 | 18.8 | 5000 | 22.5 | 5550 |

9000 | 4 | 12125 | 5 | 12150 | 5.6 | 3200 | 11.3 | 3850 | 14.4 | 4300 | 18.0 | 4800 | 22.5 | 5400 | 27 | 6000 |

10500 | 5 | 13625 | 6 | 13650 | 6.6 | 3400 | 13.1 | 4100 | 16.8 | 4600 | 21.0 | 5150 | 26.3 | 5800 | 31.5 | 6450 |

12000 | 6 | 15125 | 7 | 15150 | 7.5 | 3600 | 15.0 | 4350 | 19.2 | 4900 | 24.0 | 5500 | 30 | 6200 | 36 | 6900 |

13500 | 7 | 16625 | 8 | 16650 | 8.4 | 3800 | 16.9 | 4600 | 21.6 | 5200 | 27.0 | 5850 | 33.8 | 6600 | 40.5 | 7350 |

A | 600 | 600 | 600 | 600 | 500 | 500 | ||||||||||

B | 2400 | 2400 | 2400 | 2400 | 2000 | 2000 | ||||||||||

C | 3000 | 3000 | 3000 | 3000 | 2000 | 2000 | ||||||||||

D | 1550 | 1550 | 1650 | 1650 | 1700 | 1700 | ||||||||||

E | 1100 | 1800 | 2200 | 2600 | 3150 | 3650 | ||||||||||

Fmax | 2100 | 2800 | 3200 | 3600 | 4150 | 4650 | ||||||||||

G | 973.5 | 973.5 | 973.5 | 973.5 | 1028.5 | 1028.5 | ||||||||||

Hmax | 1348.5 | 1348.5 | 1348.5 | 1348.5 | 1403.5 | 1403.5 | ||||||||||

I | 585 | 585 | 585 | 585 | 612 | 612 | ||||||||||

J | 1104 | 1104 | 1104 | 1104 | 1163 | 1163 | ||||||||||

K | 2736 | 2736 | 3136 | 3536 | 4146 | 4646 | ||||||||||

M | 1300 | 1300 | 1300 | 1300 | 1300 | 1300 | ||||||||||

R | 1250 | 1250 | 1250 | 1250 | 1350 | 1350 | ||||||||||

S | 1400 | 2100 | 2500 | 2900 | 3450 | 3950 | ||||||||||

T | 1670 | 1670 | 1770 | 1770 | 1870 | 1870 | ||||||||||

Service Support

Whole Technological Design

Toncin determines reasonable plans and selections by conducting more systematic laboratory tests, semi-industrialization tests and theoretical analysis calculations and adopting appropriate methods in light of the actual problems faced by customers. And it determines specific parameters through laboratory tests and semi-industrial tests.

Project Construction

Toncin can provide customers with integrated project services for its perfect project management system and experienced high-quality team and can also provide customers with its best services in achieving the ultimate project goal by carrying out the management work on the project quality, schedule, safety, cost, procurement, information files, organization and coordination etc. according to customer’s contractual documents. Toncin contracts the design, procurement, construction and trials etc. for the entire process or some certain stages of the construction project according to the contract and takes full liability for the quality, safety, duration and cost etc. of the contracted project.

Response Time and After-sales Services

If any failure due to a defect has occurred during the warranty period, our company has given the following response and promise: to respond within 12 hours and rush to the domestic scene within 72 hours. With a rigorous and efficient service architecture, diverse and flexible service and response means, Toncin is capable of providing response service up to 7* 24 hours to ensure that users can get help at any time during the warranty period.

Service Support

Whole Technological Design

Toncin determines reasonable plans and selections by conducting more systematic laboratory tests, semi-industrialization tests and theoretical analysis calculations and adopting appropriate methods in light of the actual problems faced by customers. And it determines specific parameters through laboratory tests and semi-industrial tests.

Project Construction

Toncin can provide customers with integrated project services for its perfect project management system and experienced high-quality team and can also provide customers with its best services in achieving the ultimate project goal by carrying out the management work on the project quality, schedule, safety, cost, procurement, information files, organization and coordination etc. according to customer’s contractual documents. Toncin contracts the design, procurement, construction and trials etc. for the entire process or some certain stages of the construction project according to the contract and takes full liability for the quality, safety, duration and cost etc. of the contracted project.

Response Time and After-sales Services

If any failure due to a defect has occurred during the warranty period, our company has given the following response and promise: to respond within 12 hours and rush to the domestic scene within 72 hours. With a rigorous and efficient service architecture, diverse and flexible service and response means, Toncin is capable of providing response service up to 7* 24 hours to ensure that users can get help at any time during the warranty period.

Service Support

Whole Technological Design

Toncin determines reasonable plans and selections by conducting more systematic laboratory tests, semi-industrialization tests and theoretical analysis calculations and adopting appropriate methods in light of the actual problems faced by customers. And it determines specific parameters through laboratory tests and semi-industrial tests.

Project Construction

Toncin can provide customers with integrated project services for its perfect project management system and experienced high-quality team and can also provide customers with its best services in achieving the ultimate project goal by carrying out the management work on the project quality, schedule, safety, cost, procurement, information files, organization and coordination etc. according to customer’s contractual documents. Toncin contracts the design, procurement, construction and trials etc. for the entire process or some certain stages of the construction project according to the contract and takes full liability for the quality, safety, duration and cost etc. of the contracted project.

Response Time and After-sales Services

If any failure due to a defect has occurred during the warranty period, our company has given the following response and promise: to respond within 12 hours and rush to the domestic scene within 72 hours. With a rigorous and efficient service architecture, diverse and flexible service and response means, Toncin is capable of providing response service up to 7* 24 hours to ensure that users can get help at any time during the warranty period.