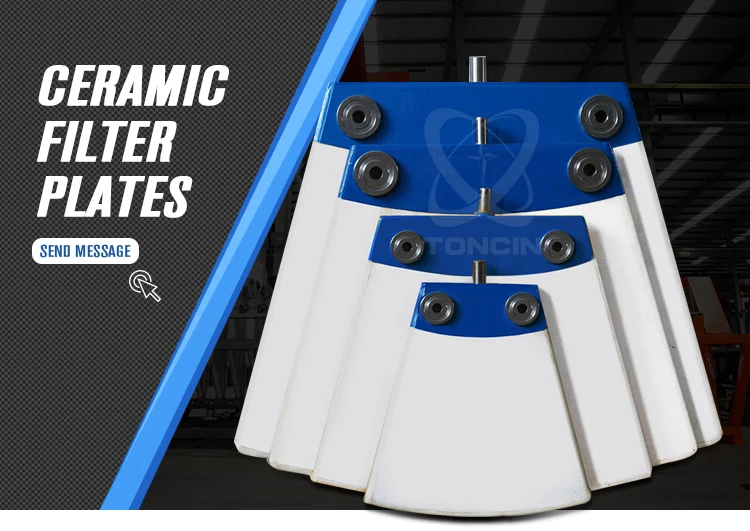

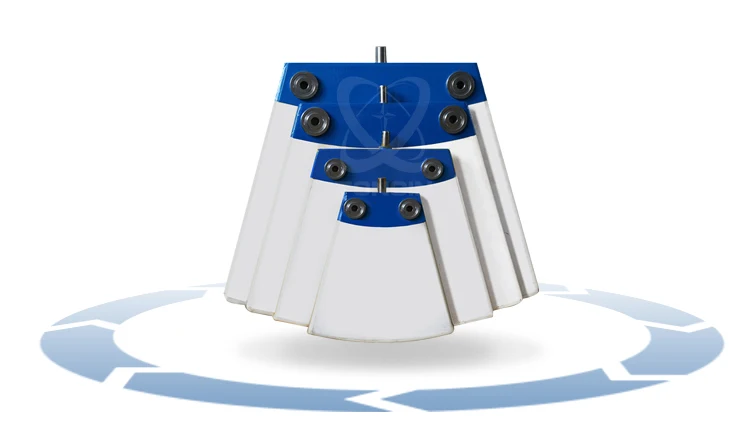

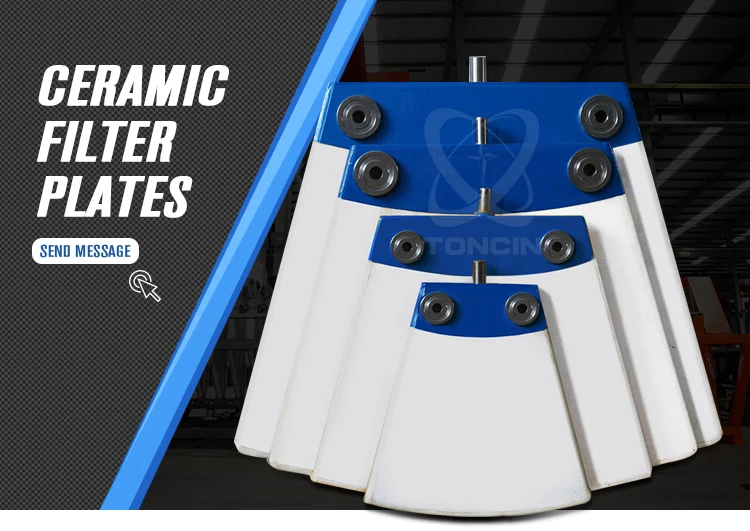

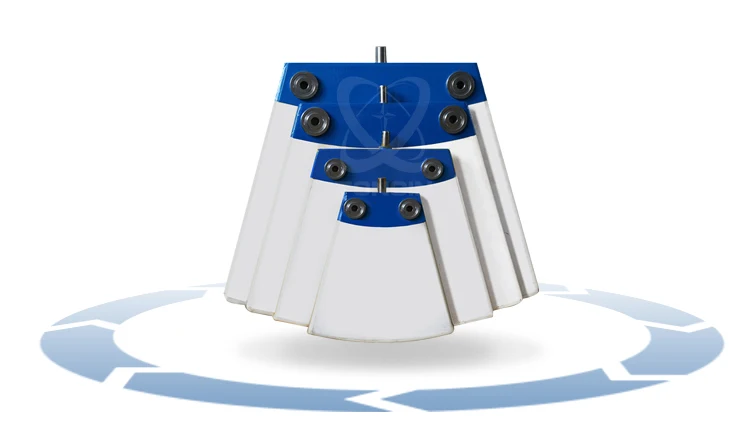

Ceramic filter plate, also known as ceramic filter, ceramic plate and filter plate, is a new filter medium made of corundum and silicon carbide by special techniques. Our ceramic filter plates have been widely used in the filter dewatering of iron concentrate, zinc concentrate, copper concentrate, nickel concentrate, aluminum concentrate, gold concentrate, and other non-metallic concentrates and the solid-liquid separation of coal, fine chemical engineering, paper, pharmaceutical, chemical fiber, food, environmental protection and other sectors.

| Availability: | |

|---|---|

| Quantity: | |

Ceramic filter plate

Toncin

Product Application:

Our company's ceramic filter plates have been widely used in filtration and dehydration of iron concentrates, zinc concentrates, sulfur concentrates, copper concentrates, nickel concentrates, aluminum concentrates, gold concentrates, non-metallic concentrates and other concentrates as well as in the solid-liquid separation in coal, fine chemicals, papermaking, pharmaceutical, chemical fiber, food, environmental protection and other industries.

Product Specification:

Descriptions | White Corundum | Brown Corundum |

Plate Area(M2) | 1,2,3,4,6 | 1,2,3,4,6 |

Coating Model(μm) | H4,H7,H10,H14-1,H14-2 | H4,H7,H10,H14-1,H14-2 |

Substrate Material Size(Mesh) | 150,180,200,220,240 | 150,180,200,220,240 |

Suitable Slurry Particle Size(μm) | 0.5,3,5,7,10,14 | 0.5,3,5,7,10,14 |

Descriptions | White Alundum | Brown Alumina | Remarks |

Specifications | 1M2 2M2 3M2 4M2 6M2 | 1M2 2M2 3M2 4M2 6M2 | Combination of best filtration and filter media |

Particle Dia Range | 0.5μm,3μm,5μm, | 0.5μm,3μm,5μm, | |

Substrate Selection(AL2O3) | 150mesh,180mesh,200mesh, | 150mesh,180mesh,200mesh, |

Product Details:

Our ceramic filters employ ceramic plates, sourced from our dedicated ceramic factory, which secured the highest volume of ceramic plate orders in China in 2014. We hold patents for our innovative IRG coating technology, known for its ability to attain a larger pore area, increased production capacity, and enhanced filtration precision. The filtration effect of our ceramic plates is customizable through the use of diverse substrates and coating materials. Our commitment to environmental responsibility is evident in restoration and recycling projects, minimizing environmental impact and costs.

Carefully chosen electrofused white steel jade undergoes gradient molding using a 500T hydraulic press, followed by an extensive sintering process at a temperature of 1430 ℃. This meticulous process ensures a remarkable high-pressure resistance of up to 8bar. The resulting membrane layer exhibits exceptional strength, while the skeleton boasts high density, providing wear resistance, pressure resistance, and corrosion resistance.

This composite material seamlessly integrates without the need for adhesive bonding, ensuring excellent water permeability with an impressive pore rate of 92%. The pre-coating process involves a 1800 mesh ultra-fine white steel jade spraying technique, enhancing the capillary effect and minimizing vacuum loss. This results in elevated filtration precision and reduced vacuum energy consumption.

Moreover, the material exhibits a high pore opening rate, allowing for substantial production capacity while maintaining exceptional filtration precision and minimizing vacuum energy requirements. Cleaning is made easy through methods such as high temperature, high pressure, organic solvents, and more. With its extended service life and diverse regeneration methods, the material's application scope is significantly broadened.

High Pressure Endurance - Superior Resistance to Cleaning Pressure - Extended Lifespan of Ceramic Plates

The ceramic plates employed in our ceramic filters boast exceptional resistance to high pressure and are specifically designed to withstand rigorous cleaning procedures, ensuring prolonged durability.

Precision in Production

Utilizing fully automated machinery, we ensure the production of consistently stable, reliable, and flat filter layers that contribute to the overall effectiveness of our filtration systems.

Proven Ceramic Expertise

Our ceramic filters incorporate ceramic plates manufactured in our professional ceramic factory, recognized for securing the majority of ceramic plate orders in China in 2014.

Innovative Coating Technology

We have secured patents for our IRG coating technology, a groundbreaking achievement that results in a higher pore area, increased production capacity, and enhanced filtration precision.

Versatile Filtration Adjustments

The filtration effect of our ceramic plates can be customized by utilizing different substrates and coating materials. This flexibility allows for tailored filtration solutions to meet specific needs.

Environmental Considerations

Our commitment extends to environmental responsibility, evident in restoration and recycling projects that minimize environmental impact and associated costs.

Product Application:

Our company's ceramic filter plates have been widely used in filtration and dehydration of iron concentrates, zinc concentrates, sulfur concentrates, copper concentrates, nickel concentrates, aluminum concentrates, gold concentrates, non-metallic concentrates and other concentrates as well as in the solid-liquid separation in coal, fine chemicals, papermaking, pharmaceutical, chemical fiber, food, environmental protection and other industries.

Product Specification:

Descriptions | White Corundum | Brown Corundum |

Plate Area(M2) | 1,2,3,4,6 | 1,2,3,4,6 |

Coating Model(μm) | H4,H7,H10,H14-1,H14-2 | H4,H7,H10,H14-1,H14-2 |

Substrate Material Size(Mesh) | 150,180,200,220,240 | 150,180,200,220,240 |

Suitable Slurry Particle Size(μm) | 0.5,3,5,7,10,14 | 0.5,3,5,7,10,14 |

Descriptions | White Alundum | Brown Alumina | Remarks |

Specifications | 1M2 2M2 3M2 4M2 6M2 | 1M2 2M2 3M2 4M2 6M2 | Combination of best filtration and filter media |

Particle Dia Range | 0.5μm,3μm,5μm, | 0.5μm,3μm,5μm, | |

Substrate Selection(AL2O3) | 150mesh,180mesh,200mesh, | 150mesh,180mesh,200mesh, |

Product Details:

Our ceramic filters employ ceramic plates, sourced from our dedicated ceramic factory, which secured the highest volume of ceramic plate orders in China in 2014. We hold patents for our innovative IRG coating technology, known for its ability to attain a larger pore area, increased production capacity, and enhanced filtration precision. The filtration effect of our ceramic plates is customizable through the use of diverse substrates and coating materials. Our commitment to environmental responsibility is evident in restoration and recycling projects, minimizing environmental impact and costs.

Carefully chosen electrofused white steel jade undergoes gradient molding using a 500T hydraulic press, followed by an extensive sintering process at a temperature of 1430 ℃. This meticulous process ensures a remarkable high-pressure resistance of up to 8bar. The resulting membrane layer exhibits exceptional strength, while the skeleton boasts high density, providing wear resistance, pressure resistance, and corrosion resistance.

This composite material seamlessly integrates without the need for adhesive bonding, ensuring excellent water permeability with an impressive pore rate of 92%. The pre-coating process involves a 1800 mesh ultra-fine white steel jade spraying technique, enhancing the capillary effect and minimizing vacuum loss. This results in elevated filtration precision and reduced vacuum energy consumption.

Moreover, the material exhibits a high pore opening rate, allowing for substantial production capacity while maintaining exceptional filtration precision and minimizing vacuum energy requirements. Cleaning is made easy through methods such as high temperature, high pressure, organic solvents, and more. With its extended service life and diverse regeneration methods, the material's application scope is significantly broadened.

High Pressure Endurance - Superior Resistance to Cleaning Pressure - Extended Lifespan of Ceramic Plates

The ceramic plates employed in our ceramic filters boast exceptional resistance to high pressure and are specifically designed to withstand rigorous cleaning procedures, ensuring prolonged durability.

Precision in Production

Utilizing fully automated machinery, we ensure the production of consistently stable, reliable, and flat filter layers that contribute to the overall effectiveness of our filtration systems.

Proven Ceramic Expertise

Our ceramic filters incorporate ceramic plates manufactured in our professional ceramic factory, recognized for securing the majority of ceramic plate orders in China in 2014.

Innovative Coating Technology

We have secured patents for our IRG coating technology, a groundbreaking achievement that results in a higher pore area, increased production capacity, and enhanced filtration precision.

Versatile Filtration Adjustments

The filtration effect of our ceramic plates can be customized by utilizing different substrates and coating materials. This flexibility allows for tailored filtration solutions to meet specific needs.

Environmental Considerations

Our commitment extends to environmental responsibility, evident in restoration and recycling projects that minimize environmental impact and associated costs.