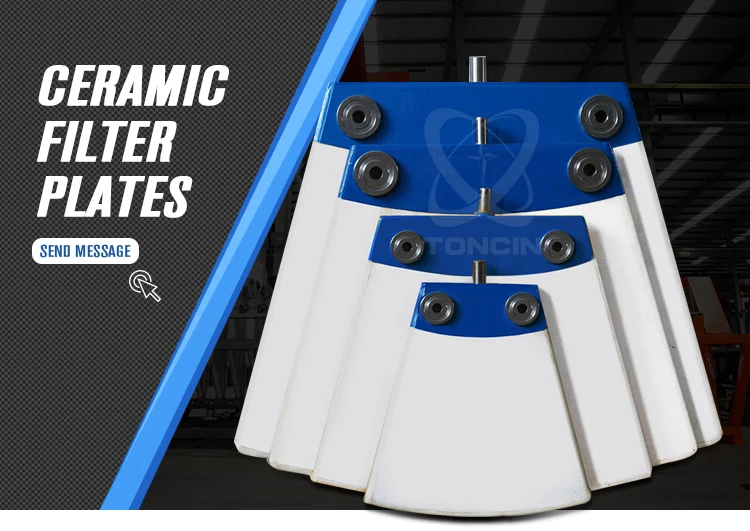

Ceramic filter plate, also known as ceramic filter, ceramic plate and filter plate, is a new filter medium made of corundum and silicon carbide by special techniques. Our ceramic filter plates have been widely used in the filter dewatering of iron concentrate, zinc concentrate, copper concentrate, nickel concentrate, aluminum concentrate, gold concentrate, and other non-metallic concentrates and the solid-liquid separation of coal, fine chemical engineering, paper, pharmaceutical, chemical fiber, food, environmental protection and other sectors.

Email: toncinfilter@toncin.com

| Availability: | |

|---|---|

| Quantity: | |

Ceramic filter plate

Toncin

Product Application:

The ceramic filter plates produced by our company are extensively utilized in the filtration and removal of water from iron concentrates, zinc concentrates, sulfur concentrates, copper concentrates, nickel concentrates, aluminum concentrates, gold concentrates, non-metallic concentrates, and other types of concentrates. These filter plates are also employed in the separation of solid and liquid substances in the coal, fine chemicals, papermaking, pharmaceutical, chemical fiber, food, environmental protection, and various other industries.

Product Specification:

Descriptions | White Corundum | Brown Corundum |

Plate Area(M2) | 1,2,3,4,6 | 1,2,3,4,6 |

Coating Model(μm) | H4,H7,H10,H14-1,H14-2 | H4,H7,H10,H14-1,H14-2 |

Substrate Material Size(Mesh) | 150,180,200,220,240 | 150,180,200,220,240 |

Suitable Slurry Particle Size(μm) | 0.5,3,5,7,10,14 | 0.5,3,5,7,10,14 |

Descriptions | White Alundum | Brown Alumina | Remarks |

Specifications | 1M2 2M2 3M2 4M2 6M2 | 1M2 2M2 3M2 4M2 6M2 | Combination of best filtration and filter media |

Particle Dia Range | 0.5μm,3μm,5μm, | 0.5μm,3μm,5μm, | |

Substrate Selection(AL2O3) | 150mesh,180mesh,200mesh, | 150mesh,180mesh,200mesh, |

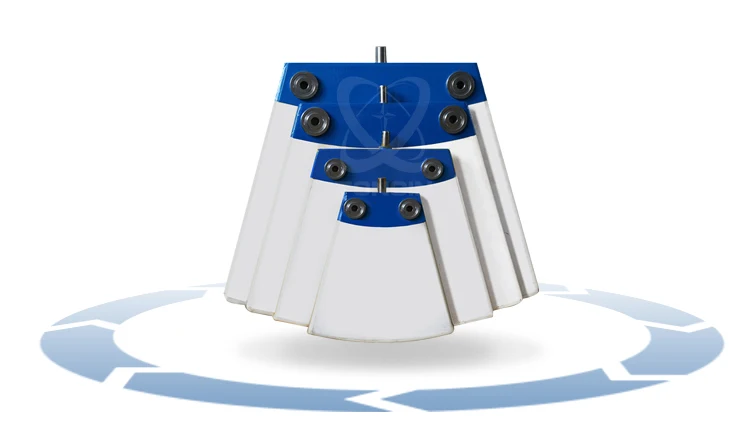

Product Details:

Ceramic filters employ ceramic plates. Our company possesses a proficient ceramic manufacturing facility that secured the largest ceramic plate order in China during 2014. We have obtained patents for our IRG coating technology, enabling us to achieve greater pore area, enhanced production capacity, and improved filtration precision. By utilizing diverse substrates and coating materials, our ceramic plates can customize the filtration effect. Implementing restoration and recycling initiatives can effectively minimize environmental harm and costs.

The electrofused white steel jade is carefully chosen using a hydraulic press and molding process. It is then sintered at a high temperature to ensure its durability and ability to withstand pressure up to 8bar. The membrane layer is strong and the skeleton is dense, making it resistant to wear, pressure, and corrosion.

This composite material is made without the use of glue, allowing for good water permeability. It has a high pore rate of 92%. The pre-coating process involves spraying the material with ultra-fine white steel jade using a 1800 mesh, resulting in a capillary effect that minimizes vacuum loss. This leads to a high filtration precision and low energy consumption for vacuuming.

The rate of pore opening is high, resulting in a large capacity for production. The filtration precision is high while consuming minimal energy. It can be easily cleaned using high temperature, high pressure, or organic solvents. It has a long lifespan and can be regenerated using various methods, which greatly expands its range of applications.

High pressure resistance---high anti-cleaning pressure—the ceramic plates have long service life

Fully automated machinery is used for the production of stable, reliable and flat filter layers.

Ceramic plates are used in ceramic filters. Our company has a professional ceramic factory which won the most order of ceramic plate of China in 2014.

Our company wins patents of IRG coating technology which can achieve higher pore area, big production Capacity and higher filtration precision.

Our ceramic plates can adjust filtration effect by using different substrate and coating material. Restoration and recycling project can reduce the damage to environment and the cost.

Service Support

Whole Technological Design

Toncin determines reasonable plans and selections by conducting more systematic laboratory tests, semi-industrialization tests and theoretical analysis calculations and adopting appropriate methods in light of the actual problems faced by customers. And it determines specific parameters through laboratory tests and semi-industrial tests.

Project Construction

Toncin can provide customers with integrated project services for its perfect project management system and experienced high-quality team and can also provide customers with its best services in achieving the ultimate project goal by carrying out the management work on the project quality, schedule, safety, cost, procurement, information files, organization and coordination etc. according to customer’s contractual documents. Toncin contracts the design, procurement, construction and trials etc. for the entire process or some certain stages of the construction project according to the contract and takes full liability for the quality, safety, duration and cost etc. of the contracted project.

Response Time and After-sales Services

If any failure due to a defect has occurred during the warranty period, our company has given the following response and promise: to respond within 12 hours and rush to the domestic scene within 72 hours. With a rigorous and efficient service architecture, diverse and flexible service and response means, Toncin is capable of providing response service up to 7* 24 hours to ensure that users can get help at any time during the warranty period.

Product Application:

The ceramic filter plates produced by our company are extensively utilized in the filtration and removal of water from iron concentrates, zinc concentrates, sulfur concentrates, copper concentrates, nickel concentrates, aluminum concentrates, gold concentrates, non-metallic concentrates, and other types of concentrates. These filter plates are also employed in the separation of solid and liquid substances in the coal, fine chemicals, papermaking, pharmaceutical, chemical fiber, food, environmental protection, and various other industries.

Product Specification:

Descriptions | White Corundum | Brown Corundum |

Plate Area(M2) | 1,2,3,4,6 | 1,2,3,4,6 |

Coating Model(μm) | H4,H7,H10,H14-1,H14-2 | H4,H7,H10,H14-1,H14-2 |

Substrate Material Size(Mesh) | 150,180,200,220,240 | 150,180,200,220,240 |

Suitable Slurry Particle Size(μm) | 0.5,3,5,7,10,14 | 0.5,3,5,7,10,14 |

Descriptions | White Alundum | Brown Alumina | Remarks |

Specifications | 1M2 2M2 3M2 4M2 6M2 | 1M2 2M2 3M2 4M2 6M2 | Combination of best filtration and filter media |

Particle Dia Range | 0.5μm,3μm,5μm, | 0.5μm,3μm,5μm, | |

Substrate Selection(AL2O3) | 150mesh,180mesh,200mesh, | 150mesh,180mesh,200mesh, |

Product Details:

Ceramic filters employ ceramic plates. Our company possesses a proficient ceramic manufacturing facility that secured the largest ceramic plate order in China during 2014. We have obtained patents for our IRG coating technology, enabling us to achieve greater pore area, enhanced production capacity, and improved filtration precision. By utilizing diverse substrates and coating materials, our ceramic plates can customize the filtration effect. Implementing restoration and recycling initiatives can effectively minimize environmental harm and costs.

The electrofused white steel jade is carefully chosen using a hydraulic press and molding process. It is then sintered at a high temperature to ensure its durability and ability to withstand pressure up to 8bar. The membrane layer is strong and the skeleton is dense, making it resistant to wear, pressure, and corrosion.

This composite material is made without the use of glue, allowing for good water permeability. It has a high pore rate of 92%. The pre-coating process involves spraying the material with ultra-fine white steel jade using a 1800 mesh, resulting in a capillary effect that minimizes vacuum loss. This leads to a high filtration precision and low energy consumption for vacuuming.

The rate of pore opening is high, resulting in a large capacity for production. The filtration precision is high while consuming minimal energy. It can be easily cleaned using high temperature, high pressure, or organic solvents. It has a long lifespan and can be regenerated using various methods, which greatly expands its range of applications.

High pressure resistance---high anti-cleaning pressure—the ceramic plates have long service life

Fully automated machinery is used for the production of stable, reliable and flat filter layers.

Ceramic plates are used in ceramic filters. Our company has a professional ceramic factory which won the most order of ceramic plate of China in 2014.

Our company wins patents of IRG coating technology which can achieve higher pore area, big production Capacity and higher filtration precision.

Our ceramic plates can adjust filtration effect by using different substrate and coating material. Restoration and recycling project can reduce the damage to environment and the cost.

Service Support

Whole Technological Design

Toncin determines reasonable plans and selections by conducting more systematic laboratory tests, semi-industrialization tests and theoretical analysis calculations and adopting appropriate methods in light of the actual problems faced by customers. And it determines specific parameters through laboratory tests and semi-industrial tests.

Project Construction

Toncin can provide customers with integrated project services for its perfect project management system and experienced high-quality team and can also provide customers with its best services in achieving the ultimate project goal by carrying out the management work on the project quality, schedule, safety, cost, procurement, information files, organization and coordination etc. according to customer’s contractual documents. Toncin contracts the design, procurement, construction and trials etc. for the entire process or some certain stages of the construction project according to the contract and takes full liability for the quality, safety, duration and cost etc. of the contracted project.

Response Time and After-sales Services

If any failure due to a defect has occurred during the warranty period, our company has given the following response and promise: to respond within 12 hours and rush to the domestic scene within 72 hours. With a rigorous and efficient service architecture, diverse and flexible service and response means, Toncin is capable of providing response service up to 7* 24 hours to ensure that users can get help at any time during the warranty period.