Applicable Industries:Energy & Mining

Condition:New

Automatic Grade:

Automatic

Place of Origin:

Shandong, China

Brand Name:Toncin

Voltage:380V, 400V, 440V, 480V

Power:10KW-50KW

Weight:8T-128T

Dimension(L*W*H):Customized

Warranty:1 Year

After-sales Service Provided: Field installation, commissioning and training, Engineers available to service machinery overseas

Description:Solid-liquid Separation Machine

Type:Vertical Filter

Operation:Fully Automatic

Item:Complete Equipment

| Availability: | |

|---|---|

| Quantity: | |

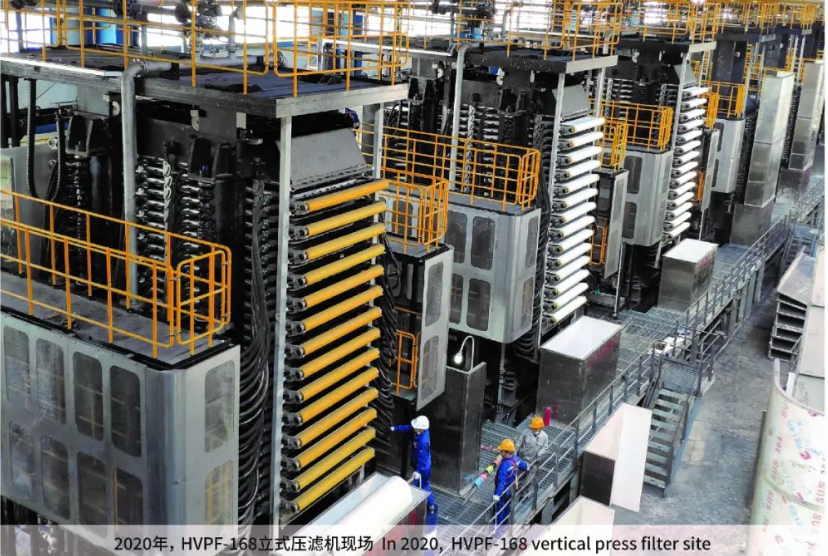

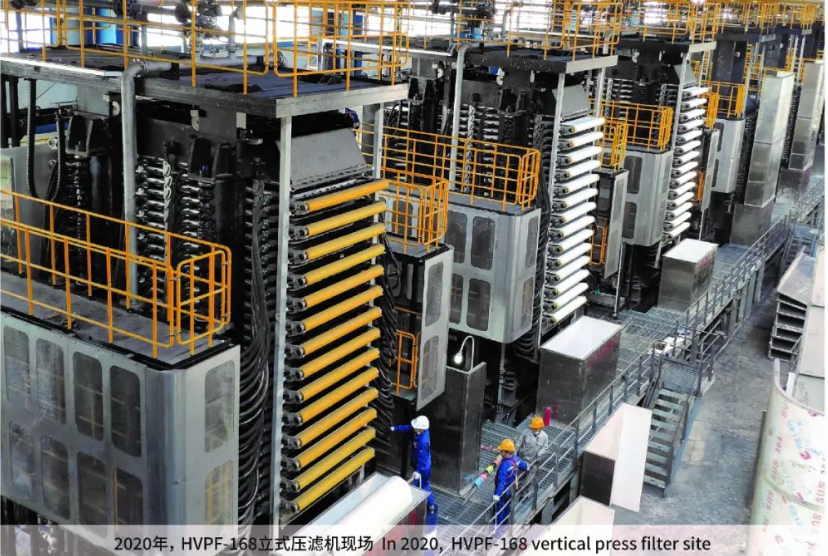

HVPF Filter Press

Toncin

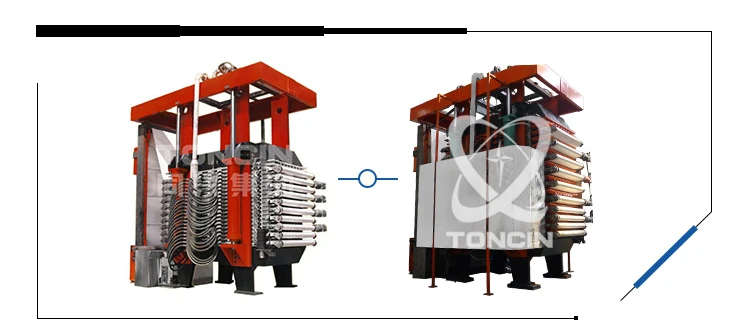

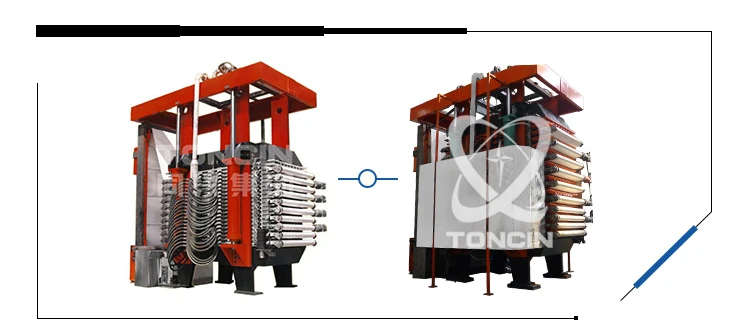

Product Introduction:

HVPF vertical automatic press filter is the most advanced filter that the world has ever get. Vacuum has a limit, but Pressure not. HVPF vertical automatic press filter use air or water to form a huge pressure difference on both sides of filter cloth to achieve very efficient separation of solid and liquid. As filter plate is closed, slurry is pumped into filter chamber through slurry pipes. Part of filtrate then enter the filtrate chamber through filter cloth because of gravity. Then high pressure water force rubber diaphragm to extrude filtrate from filter cake. When these process is finished, the driver run filter clothes and filter cakes is discharged from both sides of filter cloth.

Product Application:

HVPF vertical automatic filter press can be applied in mining, metallurgy, chemical, pharmaceutical, food and other industries. It is a large-capacity, energy-saving, automatic solid-liquid separator.

Supply Range and Requirements on Local Installation:

(1) It is composed of main machine, hydraulic station, water station, cleaning system and control system.

(2) This machine must be installed on solid flat plate reinforced concrete or steel frame. The foundation size and related dimensions refer to the installation schematic and foundation drawing. The depth of the foundation is decided by the customer according to the actual situation. The main machine should be suspended by professional technicians to avoid impact or scratching of the equipment. Use grad enter to adjust the host during installation, and install other equipment when fastening the host.

(3) air supply: particles less than 5μm, pressure 0.5-0.6MPa, air volume: subject to the assembly diagram

(4) Water supply: max. Solid content 5ppm, solid particles less than 50um, pressure 3.5-6bar, supply quantity subject to assembly drawings.

(5) Power supply: three-phase / 380 V ± 5%, single-phase / 220 V ± 5%, 50Hz

Product Specifications:

Model

| Filtrating Area(m2) | Overall Dimension m (L×W×H) | Filtrating Plate Quantity | Volume(m3) | Weight (T) | Hydraulic power (KW) | Filter plate specification (mm) | Width of filter cloth |

HVPF-1 | 1 | 2.5×1.5×2.0 | 2 | 0.05 | 8 | 7.5 | 1000*550 | 0.7 |

HVPF-2 | 2 | 2.5×1.5×2.2 | 4 | 0.09 | 9 | 7.5 | ||

HVPF-3 | 3 | 3.5×2.5×2.2 | 2 | 0.16 | 14 | 11 | 1750*900 | 1.05 |

HVPF-4 | 4 | 3.5×2.5×2.3 | 4 | 0.27 | 15 | 11 | ||

HVPF-9 | 9 | 3.5×2.5×2.5 | 6 | 0.41 | 16 | 11 | ||

HVPF-12 | 12 | 3.5×2.5×2.7 | 8 | 0.54 | 17 | 11 | ||

HVPF-15 | 15 | 3.5×2.5×2.9 | 10 | 0.68 | 18 | 11 | ||

HVPF-18 | 18 | 3.5×2.5×3.1 | 12 | 0.81 | 19 | 11 | ||

HVPF-21 | 21 | 3.5×2.5×3.3 | 14 | 0.95 | 21 | 11 | ||

HVPF-24 | 24 | 3.5×2.5×3.4 | 16 | 1.08 | 22 | 11 | ||

HVPF-27 | 27 | 3.5×2.5×3.6 | 18 | 1.22 | 23 | 11 | ||

HVPF-15 | 15 | 5.1×3.7×3.3 | 6 | 0.68 | 37 | 22 | 2500*1020 | 1.15 |

HVPF-20 | 20 | 5.1×3.7×3.6 | 8 | 0.9 | 39 | 22 | ||

HVPF-25 | 25 | 5.1×3.7×3.9 | 10 | 1.13 | 42 | 22 | ||

HVPF-30 | 30 | 5.1×3.7×4.2 | 12 | 1.35 | 43 | 22 | ||

HVPF-35 | 35 | 5.1×3.7×4.5 | 14 | 1.58 | 44 | 22 | ||

HVPF-40 | 40 | 5.1×3.7×4.8 | 16 | 1.8 | 45 | 22 | ||

HVPF-45 | 45 | 5.1×3.7×5.1 | 18 | 2.03 | 46 | 22 | ||

HVPF-50 | 50 | 5.1×3.7×5.4 | 20 | 2.25 | 48 | 22 | ||

HVPF-60 | 60 | 6.9×4.5×5.4 | 10 | 2.7 | 97 | 37 | 4010*1500 | 1.7 |

HVPF-72 | 72 | 6.9×4.5×5.8 | 12 | 3.24 | 100 | 37 | ||

HVPF-84 | 84 | 6.9×4.5×6.2 | 14 | 3.78 | 104 | 37 | ||

HVPF-96 | 96 | 6.9×4.5×6.5 | 16 | 4.32 | 110 | 37 | ||

HVPF-108 | 108 | 6.9×4.5×6.9 | 18 | 4.86 | 112 | 37 | ||

HVPF-120 | 120 | 6.9×4.5×7.2 | 20 | 5.4 | 118 | 37 | ||

HVPF-132 | 132 | 6.9×4.5×7.6 | 22 | 5.94 | 120 | 37 | ||

HVPF-144 | 144 | 6.9×4.5×7.9 | 24 | 6.48 | 123 | 37 | ||

HVPF-156 | 156 | 6.9×4.5×8.3 | 26 | 7.02 | 126 | 37 | ||

HVPF-168 | 168 | 6.9×4.5×8.6 | 28 | 7.56 | 130 | 37 | ||

HVPF-144 | 144 | 9.2×5.5×6.8 | 18 | 6.48 | 142 | 67 | 6020*1500 | 1.7 |

HVPF-162 | 162 | 9.2×5.5×7.2 | 18 | 7.29 | 147 | 67 | ||

HVPF-180 | 180 | 9.2×5.5×7.5 | 20 | 8.1 | 150 | 67 | ||

HVPF-198 | 198 | 9.2×5.5×7.8 | 22 | 8.91 | 160 | 67 | ||

HVPF-216 | 216 | 9.2×5.5×8.2 | 24 | 9.72 | 166 | 67 | ||

HVPF-234 | 234 | 9.2×5.5×8.5 | 26 | 10.53 | 172 | 67 | ||

HVPF-252 | 252 | 9.2×5.5×8.8 | 28 | 11.34 | 180 | 67 | ||

HVPF-270 | 270 | 9.2×5.5×9.2 | 30 | 12.15 | 190 | 67 |

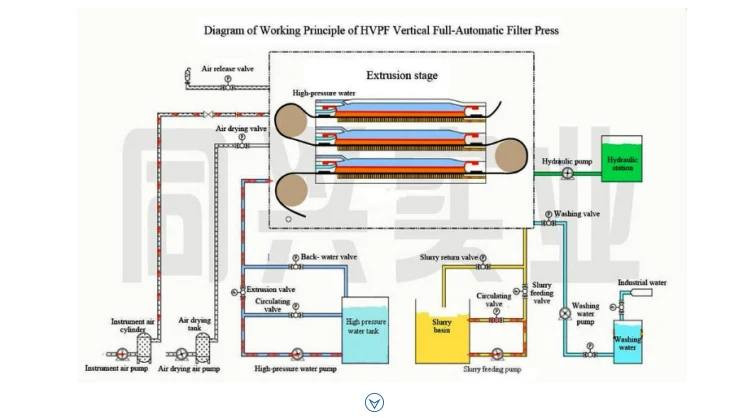

Working Process:

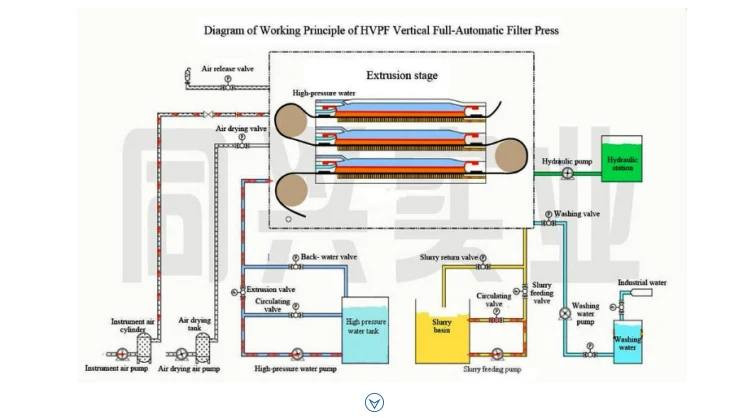

(1) Filtration stage: When the filter plate is closed, the slurry is pumped into the filtration chamber through the slurry pipe. The filtrate enters the filter chamber through the filter cloth and enters the filtrate manifold through the filter pipe, while forming the filter cake inside the chamber.

(2) Extrusion: High-pressure water enters the membrane through the pipe, so that the membrane is extruded toward the filter cake and the filtrate of the filter cake is squeezed out.

(3) Filter cake cleaning: After the filter cake is cleaned, the washing water is pumped into the filter chamber through the slurry pipe and flows into the discharge pipe through the cloth.

(4) Air-drying: The airflow with water passes through the filter cake, which can minimize the moisture of the filter cake and empty the filter chamber at the same time.

(5) Filter cake discharge: After the drying process, the driving part drives the filter cloth to run and the filter cake is discharged from both sides of the filter cloth.

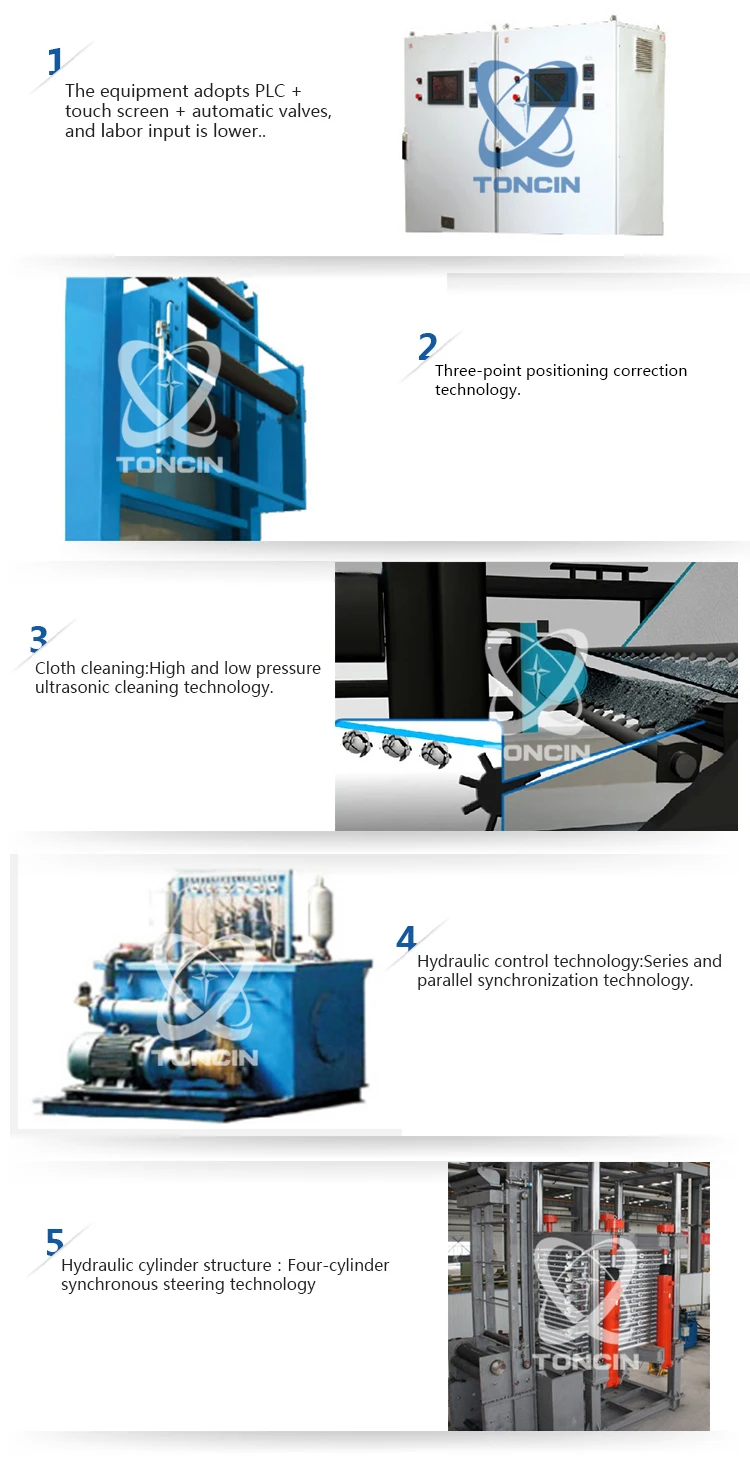

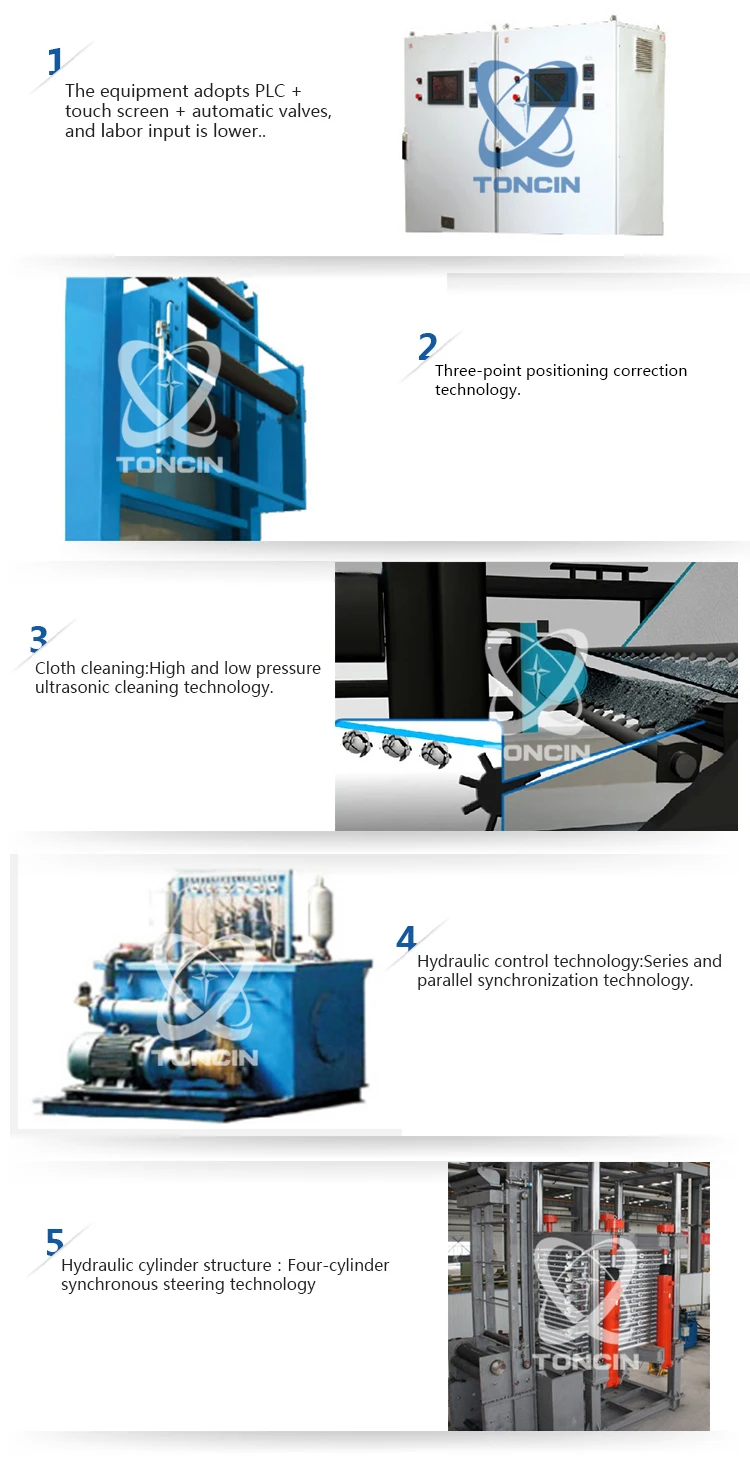

(1) The filter plate structure adopts guiding device to ensure smooth operation.

(2) It can continuously and automatically realize the operation in the process of filtering, extrusion, washing, drying, discharging and filter cloth regeneration.

(3) The filtration pressure can reach 2.0MPa, especially for various viscous fine materials and low-moisture filter cake with good effect.

(4) The key to this type of equipment is how much pressure it can withstand, but in safety. A hydraulic system is used to ensure that each plate locks well. Each nozzle and diaphragm is very carefully designed and checked to ensure the safety of the equipment when high pressure water enters the chamber.

(5) The equipment adopts PLC+touch screen+automatic valve, with less manual input.

(6) Compact structure and small footprint

Service Support

Overall process design

Toncin determines reasonable plans and options by conducting more systematic laboratory tests, semi-industrial tests and theoretical analysis and calculations, and by using appropriate methods based on the actual problems faced by the customer. Specific parameters are also determined through laboratory tests and semi-industrial tests.

Engineering Construction

With its comprehensive project management system and experienced and highly qualified team, Toncin provides customers with integrated project services and provides the best services to achieve the final project goals by managing project quality, schedule, safety, cost, procurement, information files, organization and coordination according to the customer's contract documents.Toncin contracts the entire process of construction projects or certain phases of design, procurement, construction and testing, etc. Toncin assumes full responsibility for the quality, safety, schedule and cost of the contracted project.

Response Time and After-sales Services

If any failure due to a defect has occurred during the warranty period, our company has given the following response and promise: to respond within 12 hours and rush to the domestic scene within 72 hours. With a rigorous and efficient service architecture, diverse and flexible service and response means, Toncin is capable of providing response service up to 7* 24 hours to ensure that users can get help at any time during the warranty period.

Product Introduction:

HVPF vertical automatic press filter is the most advanced filter that the world has ever get. Vacuum has a limit, but Pressure not. HVPF vertical automatic press filter use air or water to form a huge pressure difference on both sides of filter cloth to achieve very efficient separation of solid and liquid. As filter plate is closed, slurry is pumped into filter chamber through slurry pipes. Part of filtrate then enter the filtrate chamber through filter cloth because of gravity. Then high pressure water force rubber diaphragm to extrude filtrate from filter cake. When these process is finished, the driver run filter clothes and filter cakes is discharged from both sides of filter cloth.

Product Application:

HVPF vertical automatic filter press can be applied in mining, metallurgy, chemical, pharmaceutical, food and other industries. It is a large-capacity, energy-saving, automatic solid-liquid separator.

Supply Range and Requirements on Local Installation:

(1) It is composed of main machine, hydraulic station, water station, cleaning system and control system.

(2) This machine must be installed on solid flat plate reinforced concrete or steel frame. The foundation size and related dimensions refer to the installation schematic and foundation drawing. The depth of the foundation is decided by the customer according to the actual situation. The main machine should be suspended by professional technicians to avoid impact or scratching of the equipment. Use grad enter to adjust the host during installation, and install other equipment when fastening the host.

(3) air supply: particles less than 5μm, pressure 0.5-0.6MPa, air volume: subject to the assembly diagram

(4) Water supply: max. Solid content 5ppm, solid particles less than 50um, pressure 3.5-6bar, supply quantity subject to assembly drawings.

(5) Power supply: three-phase / 380 V ± 5%, single-phase / 220 V ± 5%, 50Hz

Product Specifications:

Model

| Filtrating Area(m2) | Overall Dimension m (L×W×H) | Filtrating Plate Quantity | Volume(m3) | Weight (T) | Hydraulic power (KW) | Filter plate specification (mm) | Width of filter cloth |

HVPF-1 | 1 | 2.5×1.5×2.0 | 2 | 0.05 | 8 | 7.5 | 1000*550 | 0.7 |

HVPF-2 | 2 | 2.5×1.5×2.2 | 4 | 0.09 | 9 | 7.5 | ||

HVPF-3 | 3 | 3.5×2.5×2.2 | 2 | 0.16 | 14 | 11 | 1750*900 | 1.05 |

HVPF-4 | 4 | 3.5×2.5×2.3 | 4 | 0.27 | 15 | 11 | ||

HVPF-9 | 9 | 3.5×2.5×2.5 | 6 | 0.41 | 16 | 11 | ||

HVPF-12 | 12 | 3.5×2.5×2.7 | 8 | 0.54 | 17 | 11 | ||

HVPF-15 | 15 | 3.5×2.5×2.9 | 10 | 0.68 | 18 | 11 | ||

HVPF-18 | 18 | 3.5×2.5×3.1 | 12 | 0.81 | 19 | 11 | ||

HVPF-21 | 21 | 3.5×2.5×3.3 | 14 | 0.95 | 21 | 11 | ||

HVPF-24 | 24 | 3.5×2.5×3.4 | 16 | 1.08 | 22 | 11 | ||

HVPF-27 | 27 | 3.5×2.5×3.6 | 18 | 1.22 | 23 | 11 | ||

HVPF-15 | 15 | 5.1×3.7×3.3 | 6 | 0.68 | 37 | 22 | 2500*1020 | 1.15 |

HVPF-20 | 20 | 5.1×3.7×3.6 | 8 | 0.9 | 39 | 22 | ||

HVPF-25 | 25 | 5.1×3.7×3.9 | 10 | 1.13 | 42 | 22 | ||

HVPF-30 | 30 | 5.1×3.7×4.2 | 12 | 1.35 | 43 | 22 | ||

HVPF-35 | 35 | 5.1×3.7×4.5 | 14 | 1.58 | 44 | 22 | ||

HVPF-40 | 40 | 5.1×3.7×4.8 | 16 | 1.8 | 45 | 22 | ||

HVPF-45 | 45 | 5.1×3.7×5.1 | 18 | 2.03 | 46 | 22 | ||

HVPF-50 | 50 | 5.1×3.7×5.4 | 20 | 2.25 | 48 | 22 | ||

HVPF-60 | 60 | 6.9×4.5×5.4 | 10 | 2.7 | 97 | 37 | 4010*1500 | 1.7 |

HVPF-72 | 72 | 6.9×4.5×5.8 | 12 | 3.24 | 100 | 37 | ||

HVPF-84 | 84 | 6.9×4.5×6.2 | 14 | 3.78 | 104 | 37 | ||

HVPF-96 | 96 | 6.9×4.5×6.5 | 16 | 4.32 | 110 | 37 | ||

HVPF-108 | 108 | 6.9×4.5×6.9 | 18 | 4.86 | 112 | 37 | ||

HVPF-120 | 120 | 6.9×4.5×7.2 | 20 | 5.4 | 118 | 37 | ||

HVPF-132 | 132 | 6.9×4.5×7.6 | 22 | 5.94 | 120 | 37 | ||

HVPF-144 | 144 | 6.9×4.5×7.9 | 24 | 6.48 | 123 | 37 | ||

HVPF-156 | 156 | 6.9×4.5×8.3 | 26 | 7.02 | 126 | 37 | ||

HVPF-168 | 168 | 6.9×4.5×8.6 | 28 | 7.56 | 130 | 37 | ||

HVPF-144 | 144 | 9.2×5.5×6.8 | 18 | 6.48 | 142 | 67 | 6020*1500 | 1.7 |

HVPF-162 | 162 | 9.2×5.5×7.2 | 18 | 7.29 | 147 | 67 | ||

HVPF-180 | 180 | 9.2×5.5×7.5 | 20 | 8.1 | 150 | 67 | ||

HVPF-198 | 198 | 9.2×5.5×7.8 | 22 | 8.91 | 160 | 67 | ||

HVPF-216 | 216 | 9.2×5.5×8.2 | 24 | 9.72 | 166 | 67 | ||

HVPF-234 | 234 | 9.2×5.5×8.5 | 26 | 10.53 | 172 | 67 | ||

HVPF-252 | 252 | 9.2×5.5×8.8 | 28 | 11.34 | 180 | 67 | ||

HVPF-270 | 270 | 9.2×5.5×9.2 | 30 | 12.15 | 190 | 67 |

Working Process:

(1) Filtration stage: When the filter plate is closed, the slurry is pumped into the filtration chamber through the slurry pipe. The filtrate enters the filter chamber through the filter cloth and enters the filtrate manifold through the filter pipe, while forming the filter cake inside the chamber.

(2) Extrusion: High-pressure water enters the membrane through the pipe, so that the membrane is extruded toward the filter cake and the filtrate of the filter cake is squeezed out.

(3) Filter cake cleaning: After the filter cake is cleaned, the washing water is pumped into the filter chamber through the slurry pipe and flows into the discharge pipe through the cloth.

(4) Air-drying: The airflow with water passes through the filter cake, which can minimize the moisture of the filter cake and empty the filter chamber at the same time.

(5) Filter cake discharge: After the drying process, the driving part drives the filter cloth to run and the filter cake is discharged from both sides of the filter cloth.

(1) The filter plate structure adopts guiding device to ensure smooth operation.

(2) It can continuously and automatically realize the operation in the process of filtering, extrusion, washing, drying, discharging and filter cloth regeneration.

(3) The filtration pressure can reach 2.0MPa, especially for various viscous fine materials and low-moisture filter cake with good effect.

(4) The key to this type of equipment is how much pressure it can withstand, but in safety. A hydraulic system is used to ensure that each plate locks well. Each nozzle and diaphragm is very carefully designed and checked to ensure the safety of the equipment when high pressure water enters the chamber.

(5) The equipment adopts PLC+touch screen+automatic valve, with less manual input.

(6) Compact structure and small footprint

Service Support

Overall process design

Toncin determines reasonable plans and options by conducting more systematic laboratory tests, semi-industrial tests and theoretical analysis and calculations, and by using appropriate methods based on the actual problems faced by the customer. Specific parameters are also determined through laboratory tests and semi-industrial tests.

Engineering Construction

With its comprehensive project management system and experienced and highly qualified team, Toncin provides customers with integrated project services and provides the best services to achieve the final project goals by managing project quality, schedule, safety, cost, procurement, information files, organization and coordination according to the customer's contract documents.Toncin contracts the entire process of construction projects or certain phases of design, procurement, construction and testing, etc. Toncin assumes full responsibility for the quality, safety, schedule and cost of the contracted project.

Response Time and After-sales Services

If any failure due to a defect has occurred during the warranty period, our company has given the following response and promise: to respond within 12 hours and rush to the domestic scene within 72 hours. With a rigorous and efficient service architecture, diverse and flexible service and response means, Toncin is capable of providing response service up to 7* 24 hours to ensure that users can get help at any time during the warranty period.