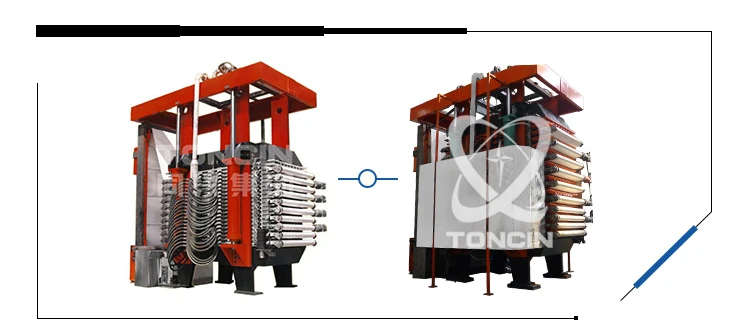

HVPF vertical automatic press filter is the most advanced filter that the world has ever get. Vacuum has a limit, but Pressure not. HVPF vertical automatic press filter use air or water to form a huge pressure difference on both sides of filter cloth to achieve very efficient separation of solid and liquid.

| Availability: | |

|---|---|

| Quantity: | |

HVPF Filter Press

Toncin

Product Introduction:

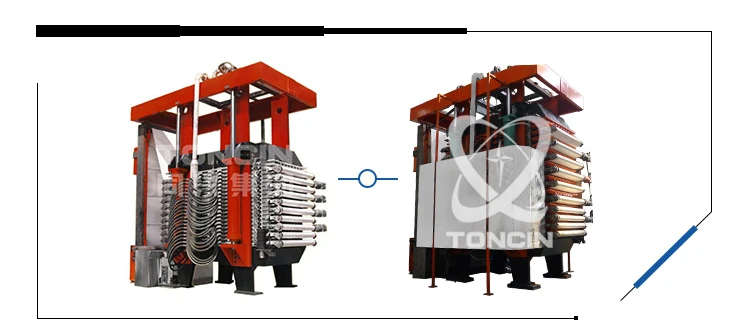

Introducing our company's latest creation, the HVPF Vertical Fully Automatic Pressure Filter. This state-of-the-art device is not only advanced, but also energy-saving and environmentally friendly. By harnessing the power of the pump, the force of gravity, and the compression of the rubber diaphragm, this cutting-edge product effectively separates solids from liquids. With its versatility, it finds applications in a wide range of industries including metallurgy, mining, chemicals, coal chemicals, titanium dioxide, paper production, food processing, pharmaceuticals, and environmental protection. When it comes to solid-liquid separation, the HVPF Vertical Fully Automatic Pressure Filter is your trustworthy and efficient solution. Rely on our expertise and invest in this exceptional product to achieve the best possible outcomes.

Product Application:

HVPF vertical automatic press filter can be applied in mining, metallurgy, chemical industry, pharmacy and food industries. It is a kind of high capacity, energy-saving, automatic solid-liquid separation machine.

Product Specifications:

Model

| Filtrating Area(m2) | Overall Dimension m (L×W×H) | Filtrating Plate Quantity | Volume(m3) | Weight (T) | Hydraulic power (KW) | Filter plate specification (mm) | Width of filter cloth |

HVPF-1 | 1 | 2.5×1.5×2.0 | 2 | 0.05 | 8 | 7.5 | 1000*550 | 0.7 |

HVPF-2 | 2 | 2.5×1.5×2.2 | 4 | 0.09 | 9 | 7.5 | ||

HVPF-3 | 3 | 3.5×2.5×2.2 | 2 | 0.16 | 14 | 11 | 1750*900 | 1.05 |

HVPF-4 | 4 | 3.5×2.5×2.3 | 4 | 0.27 | 15 | 11 | ||

HVPF-9 | 9 | 3.5×2.5×2.5 | 6 | 0.41 | 16 | 11 | ||

HVPF-12 | 12 | 3.5×2.5×2.7 | 8 | 0.54 | 17 | 11 | ||

HVPF-15 | 15 | 3.5×2.5×2.9 | 10 | 0.68 | 18 | 11 | ||

HVPF-18 | 18 | 3.5×2.5×3.1 | 12 | 0.81 | 19 | 11 | ||

HVPF-21 | 21 | 3.5×2.5×3.3 | 14 | 0.95 | 21 | 11 | ||

HVPF-24 | 24 | 3.5×2.5×3.4 | 16 | 1.08 | 22 | 11 | ||

HVPF-27 | 27 | 3.5×2.5×3.6 | 18 | 1.22 | 23 | 11 | ||

HVPF-15 | 15 | 5.1×3.7×3.3 | 6 | 0.68 | 37 | 22 | 2500*1020 | 1.15 |

HVPF-20 | 20 | 5.1×3.7×3.6 | 8 | 0.9 | 39 | 22 | ||

HVPF-25 | 25 | 5.1×3.7×3.9 | 10 | 1.13 | 42 | 22 | ||

HVPF-30 | 30 | 5.1×3.7×4.2 | 12 | 1.35 | 43 | 22 | ||

HVPF-35 | 35 | 5.1×3.7×4.5 | 14 | 1.58 | 44 | 22 | ||

HVPF-40 | 40 | 5.1×3.7×4.8 | 16 | 1.8 | 45 | 22 | ||

HVPF-45 | 45 | 5.1×3.7×5.1 | 18 | 2.03 | 46 | 22 | ||

HVPF-50 | 50 | 5.1×3.7×5.4 | 20 | 2.25 | 48 | 22 | ||

HVPF-60 | 60 | 6.9×4.5×5.4 | 10 | 2.7 | 97 | 37 | 4010*1500 | 1.7 |

HVPF-72 | 72 | 6.9×4.5×5.8 | 12 | 3.24 | 100 | 37 | ||

HVPF-84 | 84 | 6.9×4.5×6.2 | 14 | 3.78 | 104 | 37 | ||

HVPF-96 | 96 | 6.9×4.5×6.5 | 16 | 4.32 | 110 | 37 | ||

HVPF-108 | 108 | 6.9×4.5×6.9 | 18 | 4.86 | 112 | 37 | ||

HVPF-120 | 120 | 6.9×4.5×7.2 | 20 | 5.4 | 118 | 37 | ||

HVPF-132 | 132 | 6.9×4.5×7.6 | 22 | 5.94 | 120 | 37 | ||

HVPF-144 | 144 | 6.9×4.5×7.9 | 24 | 6.48 | 123 | 37 | ||

HVPF-156 | 156 | 6.9×4.5×8.3 | 26 | 7.02 | 126 | 37 | ||

HVPF-168 | 168 | 6.9×4.5×8.6 | 28 | 7.56 | 130 | 37 | ||

HVPF-144 | 144 | 9.2×5.5×6.8 | 18 | 6.48 | 142 | 67 | 6020*1500 | 1.7 |

HVPF-162 | 162 | 9.2×5.5×7.2 | 18 | 7.29 | 147 | 67 | ||

HVPF-180 | 180 | 9.2×5.5×7.5 | 20 | 8.1 | 150 | 67 | ||

HVPF-198 | 198 | 9.2×5.5×7.8 | 22 | 8.91 | 160 | 67 | ||

HVPF-216 | 216 | 9.2×5.5×8.2 | 24 | 9.72 | 166 | 67 | ||

HVPF-234 | 234 | 9.2×5.5×8.5 | 26 | 10.53 | 172 | 67 | ||

HVPF-252 | 252 | 9.2×5.5×8.8 | 28 | 11.34 | 180 | 67 | ||

HVPF-270 | 270 | 9.2×5.5×9.2 | 30 | 12.15 | 190 | 67 |

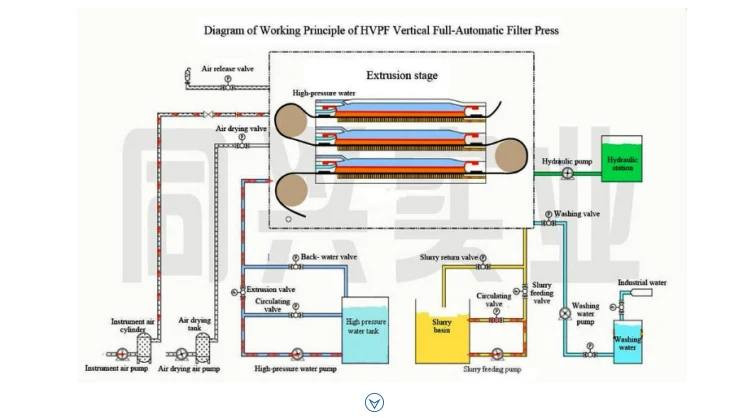

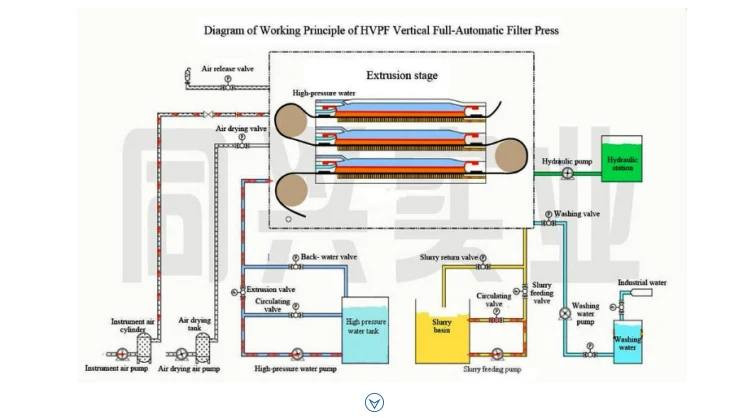

Working Process:

(1) Filtration stage: Once the filter plate is closed, the slurry is pumped into the filter chamber through a slurry pipe. The liquid passes through the filter cloth and enters the filtrate chamber, then flows into the filtrate manifold through a filtrate tube. Meanwhile, the solid particles form a filter cake within the filter chamber.

(2) Squeezing: By using a tube, high-pressure water is directed towards the filter cake, causing the filtrate to be squeezed out.

(3) Cake rinsing: The filter chamber is filled with washing water through the slurry pipe. After the cake is rinsed, the liquid flows through the cloth and into the discharge pipes.

(4) Air drying: An airflow, carrying water, passes through the filter cake. This process helps to reduce the moisture content of the filter cake to its lowest level, while also emptying the filtrate chamber.

(5) Discharging the filter cake: Once the drying process is complete, the driving components move the filter cloth, causing the filter cake to be discharged from both sides of the cloth.

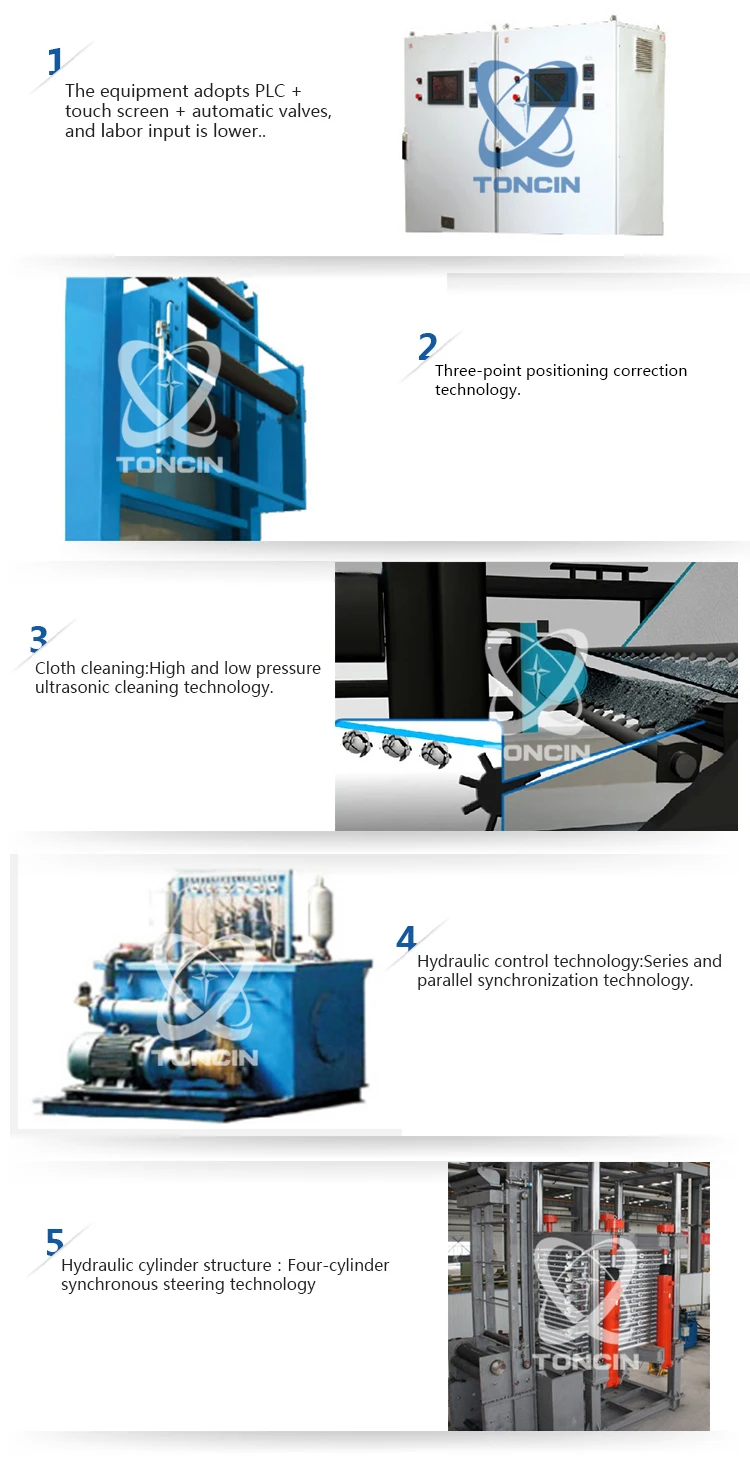

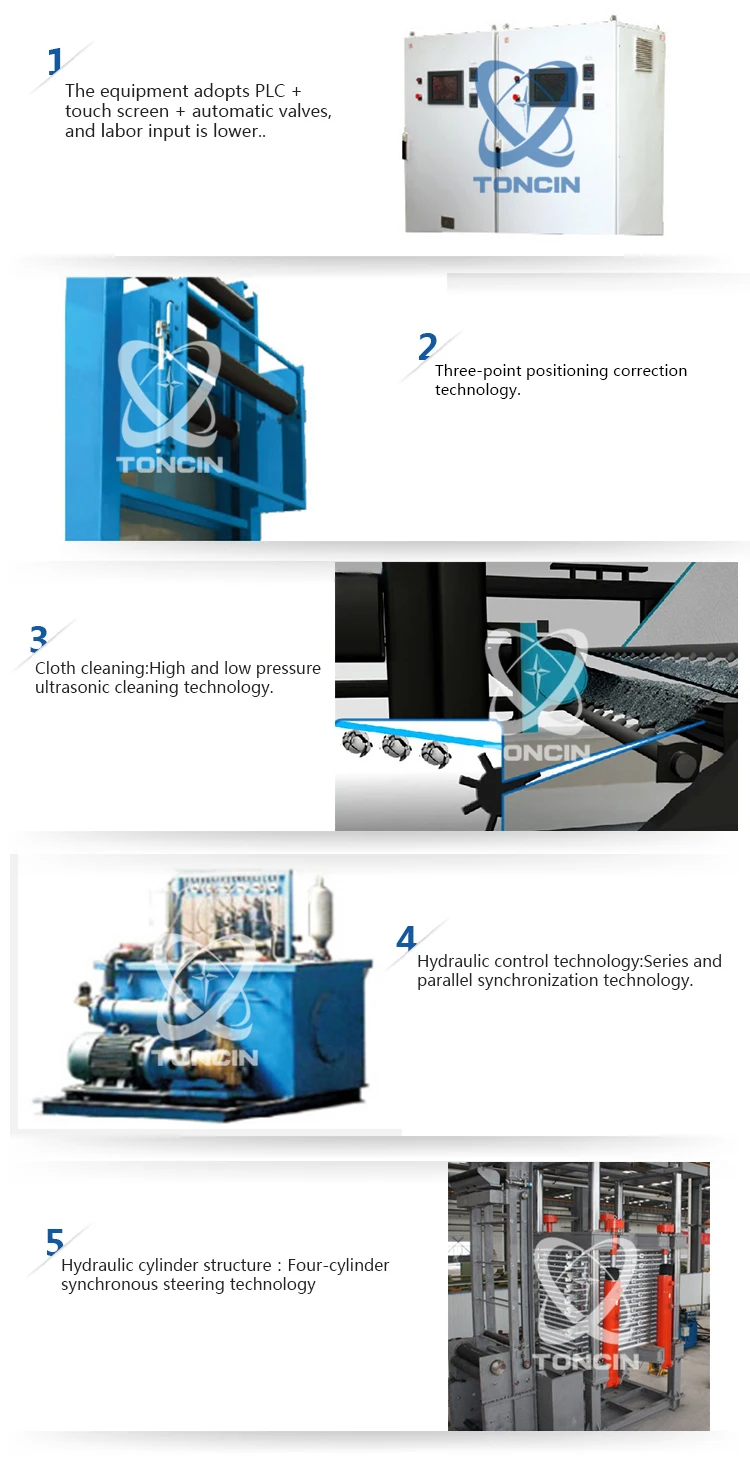

(1) The design of the filter plate includes a device that guides its operation smoothly.

(2) This machinery is capable of carrying out filtration, squeezing, washing, drying, discharging, and regenerating the filter cloth in an automatic and continuous manner.

(3) With a maximum filter pressure of 2.0 Mpa, it is highly effective in filtering sticky, small materials that have a low moisture content in the solid cake.

(4) Safety is given utmost priority in this equipment, even when operating under high pressure. The hydraulic pressure system ensures that each plate locks securely, and all nozzles and diaphragms are meticulously designed and inspected to prevent any accidents.

(5) The equipment is equipped with a Programmable Logic Controller (PLC), touch screen, and automatic valves, which require minimal manual input.

(6) Its compact structure occupies a smaller area of the floor.

Service Support

Whole Technological Design

Toncin determines reasonable plans and selections by conducting more systematic laboratory tests, semi-industrialization tests and theoretical analysis calculations and adopting appropriate methods in light of the actual problems faced by customers. And it determines specific parameters through laboratory tests and semi-industrial tests.

Project Construction

Toncin can provide customers with integrated project services for its perfect project management system and experienced high-quality team and can also provide customers with its best services in achieving the ultimate project goal by carrying out the management work on the project quality, schedule, safety, cost, procurement, information files, organization and coordination etc. according to customer’s contractual documents. Toncin contracts the design, procurement, construction and trials etc. for the entire process or some certain stages of the construction project according to the contract and takes full liability for the quality, safety, duration and cost etc. of the contracted project.

Response Time and After-sales Services

In case of any malfunction within the warranty period, our company guarantees a prompt and dedicated response. We commit to addressing the issue within 12 hours and reaching the customer's location within 72 hours. With a well-structured and efficient service system, we offer a wide range of flexible and responsive solutions. Toncin strives to provide round-the-clock assistance throughout the warranty period, ensuring users receive timely support whenever they need it.

Product Introduction:

Introducing our company's latest creation, the HVPF Vertical Fully Automatic Pressure Filter. This state-of-the-art device is not only advanced, but also energy-saving and environmentally friendly. By harnessing the power of the pump, the force of gravity, and the compression of the rubber diaphragm, this cutting-edge product effectively separates solids from liquids. With its versatility, it finds applications in a wide range of industries including metallurgy, mining, chemicals, coal chemicals, titanium dioxide, paper production, food processing, pharmaceuticals, and environmental protection. When it comes to solid-liquid separation, the HVPF Vertical Fully Automatic Pressure Filter is your trustworthy and efficient solution. Rely on our expertise and invest in this exceptional product to achieve the best possible outcomes.

Product Application:

HVPF vertical automatic press filter can be applied in mining, metallurgy, chemical industry, pharmacy and food industries. It is a kind of high capacity, energy-saving, automatic solid-liquid separation machine.

Product Specifications:

Model

| Filtrating Area(m2) | Overall Dimension m (L×W×H) | Filtrating Plate Quantity | Volume(m3) | Weight (T) | Hydraulic power (KW) | Filter plate specification (mm) | Width of filter cloth |

HVPF-1 | 1 | 2.5×1.5×2.0 | 2 | 0.05 | 8 | 7.5 | 1000*550 | 0.7 |

HVPF-2 | 2 | 2.5×1.5×2.2 | 4 | 0.09 | 9 | 7.5 | ||

HVPF-3 | 3 | 3.5×2.5×2.2 | 2 | 0.16 | 14 | 11 | 1750*900 | 1.05 |

HVPF-4 | 4 | 3.5×2.5×2.3 | 4 | 0.27 | 15 | 11 | ||

HVPF-9 | 9 | 3.5×2.5×2.5 | 6 | 0.41 | 16 | 11 | ||

HVPF-12 | 12 | 3.5×2.5×2.7 | 8 | 0.54 | 17 | 11 | ||

HVPF-15 | 15 | 3.5×2.5×2.9 | 10 | 0.68 | 18 | 11 | ||

HVPF-18 | 18 | 3.5×2.5×3.1 | 12 | 0.81 | 19 | 11 | ||

HVPF-21 | 21 | 3.5×2.5×3.3 | 14 | 0.95 | 21 | 11 | ||

HVPF-24 | 24 | 3.5×2.5×3.4 | 16 | 1.08 | 22 | 11 | ||

HVPF-27 | 27 | 3.5×2.5×3.6 | 18 | 1.22 | 23 | 11 | ||

HVPF-15 | 15 | 5.1×3.7×3.3 | 6 | 0.68 | 37 | 22 | 2500*1020 | 1.15 |

HVPF-20 | 20 | 5.1×3.7×3.6 | 8 | 0.9 | 39 | 22 | ||

HVPF-25 | 25 | 5.1×3.7×3.9 | 10 | 1.13 | 42 | 22 | ||

HVPF-30 | 30 | 5.1×3.7×4.2 | 12 | 1.35 | 43 | 22 | ||

HVPF-35 | 35 | 5.1×3.7×4.5 | 14 | 1.58 | 44 | 22 | ||

HVPF-40 | 40 | 5.1×3.7×4.8 | 16 | 1.8 | 45 | 22 | ||

HVPF-45 | 45 | 5.1×3.7×5.1 | 18 | 2.03 | 46 | 22 | ||

HVPF-50 | 50 | 5.1×3.7×5.4 | 20 | 2.25 | 48 | 22 | ||

HVPF-60 | 60 | 6.9×4.5×5.4 | 10 | 2.7 | 97 | 37 | 4010*1500 | 1.7 |

HVPF-72 | 72 | 6.9×4.5×5.8 | 12 | 3.24 | 100 | 37 | ||

HVPF-84 | 84 | 6.9×4.5×6.2 | 14 | 3.78 | 104 | 37 | ||

HVPF-96 | 96 | 6.9×4.5×6.5 | 16 | 4.32 | 110 | 37 | ||

HVPF-108 | 108 | 6.9×4.5×6.9 | 18 | 4.86 | 112 | 37 | ||

HVPF-120 | 120 | 6.9×4.5×7.2 | 20 | 5.4 | 118 | 37 | ||

HVPF-132 | 132 | 6.9×4.5×7.6 | 22 | 5.94 | 120 | 37 | ||

HVPF-144 | 144 | 6.9×4.5×7.9 | 24 | 6.48 | 123 | 37 | ||

HVPF-156 | 156 | 6.9×4.5×8.3 | 26 | 7.02 | 126 | 37 | ||

HVPF-168 | 168 | 6.9×4.5×8.6 | 28 | 7.56 | 130 | 37 | ||

HVPF-144 | 144 | 9.2×5.5×6.8 | 18 | 6.48 | 142 | 67 | 6020*1500 | 1.7 |

HVPF-162 | 162 | 9.2×5.5×7.2 | 18 | 7.29 | 147 | 67 | ||

HVPF-180 | 180 | 9.2×5.5×7.5 | 20 | 8.1 | 150 | 67 | ||

HVPF-198 | 198 | 9.2×5.5×7.8 | 22 | 8.91 | 160 | 67 | ||

HVPF-216 | 216 | 9.2×5.5×8.2 | 24 | 9.72 | 166 | 67 | ||

HVPF-234 | 234 | 9.2×5.5×8.5 | 26 | 10.53 | 172 | 67 | ||

HVPF-252 | 252 | 9.2×5.5×8.8 | 28 | 11.34 | 180 | 67 | ||

HVPF-270 | 270 | 9.2×5.5×9.2 | 30 | 12.15 | 190 | 67 |

Working Process:

(1) Filtration stage: Once the filter plate is closed, the slurry is pumped into the filter chamber through a slurry pipe. The liquid passes through the filter cloth and enters the filtrate chamber, then flows into the filtrate manifold through a filtrate tube. Meanwhile, the solid particles form a filter cake within the filter chamber.

(2) Squeezing: By using a tube, high-pressure water is directed towards the filter cake, causing the filtrate to be squeezed out.

(3) Cake rinsing: The filter chamber is filled with washing water through the slurry pipe. After the cake is rinsed, the liquid flows through the cloth and into the discharge pipes.

(4) Air drying: An airflow, carrying water, passes through the filter cake. This process helps to reduce the moisture content of the filter cake to its lowest level, while also emptying the filtrate chamber.

(5) Discharging the filter cake: Once the drying process is complete, the driving components move the filter cloth, causing the filter cake to be discharged from both sides of the cloth.

(1) The design of the filter plate includes a device that guides its operation smoothly.

(2) This machinery is capable of carrying out filtration, squeezing, washing, drying, discharging, and regenerating the filter cloth in an automatic and continuous manner.

(3) With a maximum filter pressure of 2.0 Mpa, it is highly effective in filtering sticky, small materials that have a low moisture content in the solid cake.

(4) Safety is given utmost priority in this equipment, even when operating under high pressure. The hydraulic pressure system ensures that each plate locks securely, and all nozzles and diaphragms are meticulously designed and inspected to prevent any accidents.

(5) The equipment is equipped with a Programmable Logic Controller (PLC), touch screen, and automatic valves, which require minimal manual input.

(6) Its compact structure occupies a smaller area of the floor.

Service Support

Whole Technological Design

Toncin determines reasonable plans and selections by conducting more systematic laboratory tests, semi-industrialization tests and theoretical analysis calculations and adopting appropriate methods in light of the actual problems faced by customers. And it determines specific parameters through laboratory tests and semi-industrial tests.

Project Construction

Toncin can provide customers with integrated project services for its perfect project management system and experienced high-quality team and can also provide customers with its best services in achieving the ultimate project goal by carrying out the management work on the project quality, schedule, safety, cost, procurement, information files, organization and coordination etc. according to customer’s contractual documents. Toncin contracts the design, procurement, construction and trials etc. for the entire process or some certain stages of the construction project according to the contract and takes full liability for the quality, safety, duration and cost etc. of the contracted project.

Response Time and After-sales Services

In case of any malfunction within the warranty period, our company guarantees a prompt and dedicated response. We commit to addressing the issue within 12 hours and reaching the customer's location within 72 hours. With a well-structured and efficient service system, we offer a wide range of flexible and responsive solutions. Toncin strives to provide round-the-clock assistance throughout the warranty period, ensuring users receive timely support whenever they need it.