Views: 0 Author: Site Editor Publish Time: 2026-01-29 Origin: Site

A corrugated sidewall conveyor belt carries lots of materials. It can move things on flat or steep paths. This conveyor has a base belt, sidewalls that bend, and cleats. These parts stop materials from falling off. You can find these conveyor systems in ports, mines, and chemical plants. They work well on steep slopes and help save space. If you know how this conveyor works, you can pick the best system. This helps move things safely and quickly in hard work places.

Corrugated sidewall conveyor belts move things up steep slopes. They do not let things spill. This makes them good for small spaces. The special design has sidewalls and cleats. These make pockets that stop items from falling off. These belts use less energy. They need less power and care. This helps save money over time. Picking the right materials makes the belt stronger. It also helps it work better and last longer in hard places. People use these belts in many jobs, like mining and food processing. This shows how useful corrugated sidewall conveyor belts are in different industries.

A corrugated sidewall conveyor belt looks different because of its special shape. It uses a base belt made from strong rubber. The belt has sidewalls on both sides. These sidewalls look wavy and can bend easily. They help keep materials on the belt, even on steep slopes. Cleats are upright strips across the belt. They act like small walls and stop things from sliding back.

Tip: Picking the right material helps your conveyor last longer. Good rubber does not wear out fast. It also does not tear or break easily. You can pick different carcass types for different loads.

Here is a table that shows common materials and how tough they are:

Material Type | Durability Features |

|---|---|

High-Quality Rubber | Very strong against wearing, hitting, and tearing. |

Carcass Options | Many choices for different weights and uses. |

Common Belt Rating | Goes from 200 to 3150 kN/m for carrying heavy loads. |

The special design of the corrugated sidewall conveyor belt lets you move things at steeper angles than normal belts. The sidewalls and cleats make pockets. These pockets hold loose or big items in place.

When you use a corrugated sidewall conveyor belt, you can move things up, down, or straight up. The base belt moves forward and carries everything on top. The raised sidewalls make pockets so things do not fall off the sides. Cleats stop things from rolling or sliding back, even on steep hills.

The sidewalls give more support and keep things steady.

The cleats act like walls for loose stuff.

The flexible belt lets you move things at angles up to 30° to 35° without losing anything.

Here is a table that shows how the design helps with steep slopes and keeps things steady:

Feature | Description |

|---|---|

Load Handling | Can carry heavier things than regular belts. |

Incline Capability | Made to work well on steep slopes. |

Support and Stability | The sidewalls give extra support and stop spills. |

Angle of Conveying | Good for moving things at angles up to 90°. |

Operational Efficiency | Needs fewer transfer spots, saves energy, and costs less to run. |

You will see that the corrugated sidewall conveyor belt works well in small spaces. It can move things at sharp angles, so you do not need long, flat belts. The way it moves stops spills by making safe pockets with the sidewalls and cleats. This design lets you carry loose or big things safely, even at steep angles.

Raised sidewalls make pockets that hold things while moving.

Cleats stop things from rolling back on steep slopes.

The flexible belt lets you move things straight up or almost straight up.

If you need to move things up steep hills or in tight spots, this conveyor is a good and safe choice.

A corrugated sidewall belt conveyor has three main parts. Each part helps move things safely and fast.

The base belt sits in the middle of the conveyor. It holds all the things you want to move. The belt is made with strong fabric and cover layers. These layers make the belt tough and protect it from damage. The base belt must carry heavy things and keep its shape. It works well even on long or steep paths. Here is a table that shows how the base belt’s features help it work:

Factor | Impact on Performance |

|---|---|

Tensile Strength | Lets you move heavy or dense materials without breaking. |

Structural Integrity | Keeps the belt working well on long or steep conveyors. |

Environmental Resistance | Protects the belt from heat, oil, UV rays, and chemicals. |

You can pick different base belt types for your job. Some belts have more layers for extra strength. Others have special covers for better grip or protection.

Sidewalls go along both sides of the base belt. They look wavy and can bend easily. These sidewalls stop things from falling off, even on steep slopes. You can choose sidewall heights from 35mm to 360mm. Pick the height based on what you need to move. The sidewalls also help the belt last longer. They make the belt strong and flexible.

Note: Flexible sidewalls let you move things up steep slopes. They also help stop spills and keep things steady while moving.

Cleats are upright strips across the belt between the sidewalls. They act like small walls to hold things in place. Cleats come in many shapes and sizes. Some are good for light loads. Others are made for heavy or rough things. For example, U-shaped cleats stop things from sliding back on steep slopes. Special cleat shapes can cut down spills by up to 40% compared to flat belts. Here is a table with some common cleat types and what they do:

Cleat Type | Applications |

|---|---|

Steep Climber Cleats | Large items, steep angles |

Mini Cleats | Light-duty, gentle inclines |

Steel-Reinforced Cleats | Rugged, heavy-duty jobs |

Curved PVC Cleats | Food-grade, incline use |

Urethane Chevron Cleats | Durable, custom incline jobs |

Cleats and sidewalls together let you move things almost straight up. They also let the conveyor carry up to four times more than regular belts.

If you pick sidewall conveyor belts, you get many good things for your work. These belts help you move more stuff, save space, and use less energy. Let’s see what each benefit means.

A corrugated sidewall conveyor belt can carry much more than a regular conveyor. Its special shape lets you move things up steep slopes. You do not lose material while moving. This helps you finish jobs faster and do more work.

Conveyor Type | Capacity Increase |

|---|---|

Corrugated Sidewall Conveyor | 1-2 times higher than traditional conveyor belts |

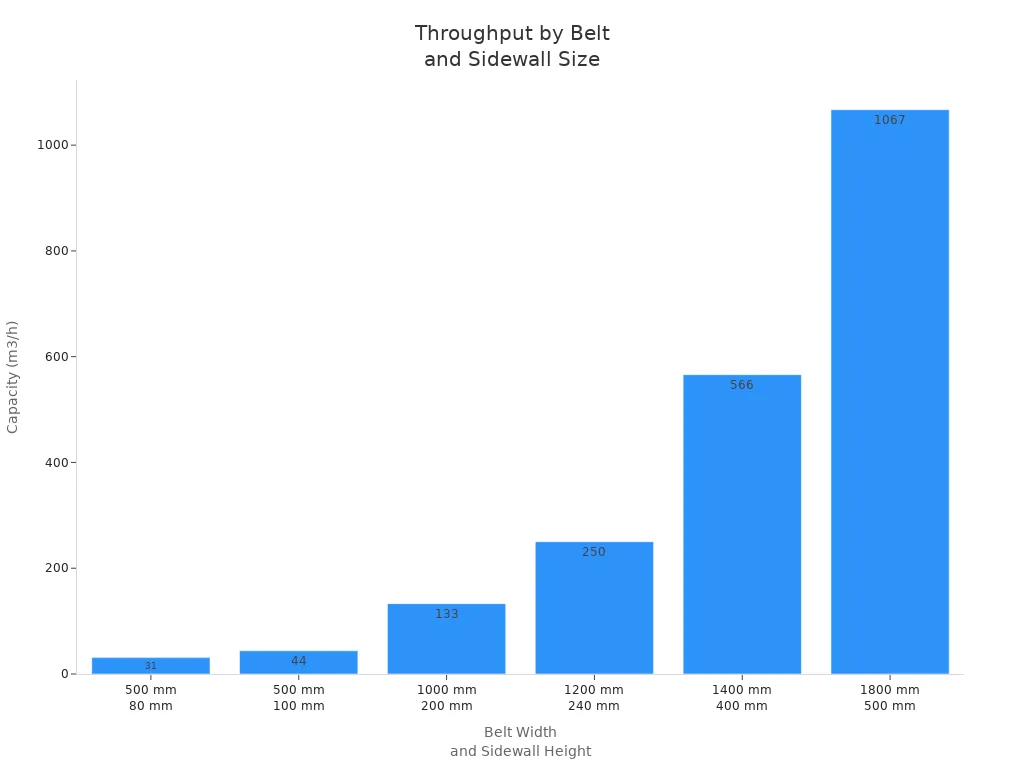

The table shows you can get up to twice as much capacity as normal belts. Here are some common rates for moving materials:

Belt Width (mm) | Sidewall Height (mm) | Speed Range (m/s) | Capacity (m³/h) |

|---|---|---|---|

500 | 80 | 0.8-1.25 | 31 |

1000 | 200 | 1.0-2.5 | 133 |

1400 | 400 | 1.0-3.15 | 566 |

1800 | 500 | 1.25-3.15 | 1067 |

You can put sidewall conveyor belts in small places. These belts move things up very steep slopes, even straight up. You do not need long, flat machines anymore.

Vertical lifting and Z-shaped layouts fit in tight spaces.

High-incline systems use less floor space, so you have more room for other jobs.

Conveyor Type | Installation Footprint | Advantages |

|---|---|---|

Corrugated Sidewall Conveyor | Smaller | Can work at angles up to 90°, so you need less space for setup. |

Conventional Conveyor Systems | Larger | Usually only work up to 18°, so they need more space and length. |

These conveyor belts help you save energy. Their simple design makes them quiet and easy to run. There are fewer moving parts, so you need less power and do less fixing. Steep angles mean the conveyor is shorter, which saves even more energy.

Tip: Using one conveyor for steep slopes means you spend less money and use less power.

Sidewall conveyor belts give you high capacity, save space, and lower energy costs. These things make them a smart pick for many jobs.

Corrugated sidewall conveyor belts are used in many industries. These belts help move things safely and fast, even in hard places. Here are some ways people use them:

Coal and wood chip-fired power plants

Underground ore and coal mines

Tunneling and mining shafts

Iron and steel production

Ship loading and unloading

Sand recycling in foundries

Scrap recycling for steel, cans, and paper

Silo feed systems

Hi-wall transport in open-pit mines

High-volume horizontal transportation

Waste recovery and water treatment

These belts are good when you need to carry a lot or move things up steep slopes.

You can use these conveyor belts to move many things. The table below shows what different industries move with them:

Industry | Materials/Usage |

|---|---|

Food Processing | Rice, wheat, corn, chips, candies, nuts, frozen foods, salt, sugar |

Chemical Industry | PE/PP/PVC particles, urea, fertilizer, quartz sand, calcium carbonate |

Logistics & Warehousing | E-commerce packages, boxed goods, bulk cargo |

Pharmaceutical Manufacturing | Tablets, capsules, syringes, infusion bottles |

Other Industrial Fields | Cement, tiles, glass raw materials, lithium battery parts |

The size, shape, and weight of what you move is important. If you need to move big or rough things, pick a belt that is strong and does not wear out fast. Where you use the belt, like if it is hot or wet, also matters.

Pick a corrugated edge conveyor if you want to move things all the time without spills. These belts work at any angle, even straight up, so you save space and do not need extra machines. The design lets you move things of any size, even up to 400mm, and carry loads from 1m³/h to 6,000m³/h.

Decision Factor | Description |

|---|---|

Material and Construction | The inside of the belt helps move things far |

Sidewall Design | Stops things from sliding, even on steep slopes |

Conveying Conditions | Works in hot, cold, or with many types of things |

Maintenance and Service Life | Easy to fix, lasts longer, and costs less |

Cost-Benefit Analysis | Saves money because you fix it less and it breaks less |

Tip: You can get special sidewalls or cleats to fit your job.

You get a strong, bendy, and trustworthy system for many jobs. This makes sidewall conveyor belts a smart pick for moving things today.

You can make moving materials better with a corrugated sidewall conveyor. This system helps keep your work area safe and clean. It can carry heavy things and go up steep slopes easily. You will save money because it does not need much fixing and uses less energy. The table below shows why many companies like this system:

Advantage | Description |

|---|---|

Practically Zero Spillage | Keeps materials on the belt, so you waste less and clean up less. |

Minimum Maintenance | Works well and does not stop often. |

Low Energy Consumption | Uses less power, so your bills are lower. |

Reduced Installation Space | Fits in small spaces and saves floor space. |

Durable Parts | Lasts a long time, so you do not change parts often. |

Think about using this conveyor for your next job if you want a system that is strong, saves money, and works well.

You see sidewalls and cleats on this belt. These parts keep materials from falling off. You can move things up steep slopes. Regular belts cannot do this.

Yes, you can use it outdoors. The belt resists weather, sunlight, and water. You should pick the right material for your climate.

Use a soft brush or air blower to remove dust and debris. For sticky materials, use water and mild soap. Always turn off the conveyor before cleaning.

Material Type | Examples |

|---|---|

Bulk solids | Sand, coal, grain |

Packaged goods | Boxes, bags, cartons |

Food items | Chips, nuts, candies |

You can move many types of materials safely.