Views: 0 Author: Site Editor Publish Time: 2025-03-26 Origin: Site

Separating solids from liquids is a critical process in various industries, including pharmaceuticals, food and beverage, water treatment, and mining. Whether it’s purifying water, removing contaminants from chemicals, or isolating valuable products, selecting the right machine for the job is essential to optimize efficiency, cost-effectiveness, and environmental sustainability. But what machine separates liquids from solids?

In this article, we explore different types of machines designed to perform solid-liquid separation.

Solid-liquid separation plays a fundamental role in many industrial processes. Whether it’s for waste treatment, producing clean water, or processing food ingredients, these separations can help businesses improve product quality, enhance operational efficiency, and comply with environmental standards.

Separation processes are not one-size-fits-all; the equipment used depends on the type of solid-liquid mixture, the desired output, and the scale of the operation. With the right separation equipment, companies can achieve higher yields, reduced waste, and minimized energy consumption.

Different machines are used to separate solids from liquids, depending on the nature of the material being processed. Let’s explore the most common machines used in solid-liquid separation.

A centrifugeis one of the most effective machines used to separate liquids from solids. By using centrifugal force, a centrifuge spins the mixture at high speeds, causing the denser solid particles to move outward while the liquid phase stays closer to the center. This method is ideal for separating fine solids or when gravity alone is insufficient.

Centrifuges are widely used in industries like chemical processing, pharmaceuticals, food production, and wastewater treatment. They are particularly effective for separating particles that are difficult to remove by other methods.

● High efficiency: Centrifuges can separate solids from liquids at a very fine level, making them ideal for industries that require high purity.

● Continuous operation: Most centrifuges are designed for continuous operation, which is essential for large-scale industrial processes.

● Versatility: Centrifuges can be used to separate a wide range of materials, from large particles in slurry to fine chemicals in pharmaceutical manufacturing.

Product Example: Nuclear Industry Yantai Toncin Group Co., Ltd. offers advanced centrifuge systems that use cutting-edge technology to achieve superior separation results. Their centrifuges are designed for various industries, ensuring optimal performance and energy efficiency.

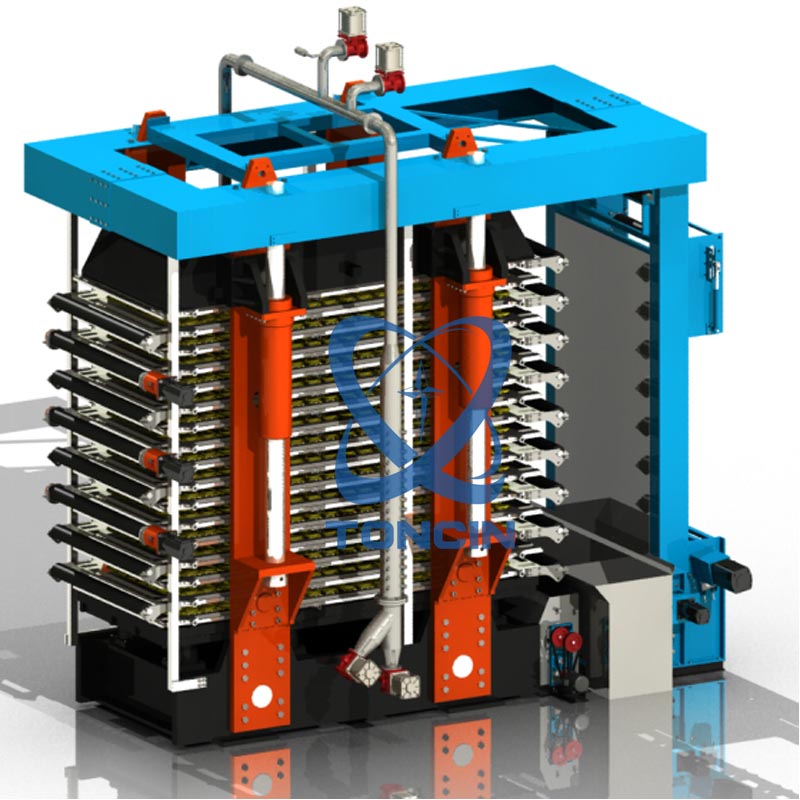

Filter presses are widely used in industries that need to separate large volumes of solid and liquid mixtures, such as mining, water treatment, and food processing. A filter press consists of a series of plates that are covered with filter cloths. The slurry is pumped into the filter press, where the liquid passes through the filter cloths, leaving the solid particles behind.

● High filtration capacity: Filter presses can process large volumes of slurry and produce a high-quality filtrate.

● Efficient solid recovery: The process can recover a significant amount of solids, which can be recycled or disposed of.

● Easy operation: Filter presses are simple to operate, making them suitable for industries with varying levels of technical expertise.

Product Example: The filter presses from Yantai Toncin are designed for high-performance filtration. These machines provide excellent separation of liquids and solids, even in challenging applications where large volumes of slurry need to be processed.

Vacuum filters are another popular machine for separating solids from liquids. This machine works by applying a vacuum to the filter surface, which draws the liquid through the filter media while leaving the solids behind. This is an excellent method when it is necessary to remove moisture from solids.

Vacuum filters are commonly used in industries such as food processing, chemical production, and wastewater treatment.

● Effective dewatering: Vacuum filters are particularly effective for removing moisture from slurries, which is crucial in many industrial processes.

● High filtration efficiency: These machines can produce a high-quality filtrate and are particularly useful when dealing with fine particles.

● Scalable: Vacuum filters can be adapted to both small-scale operations and large industrial plants.

Product Example: Nuclear Industry Yantai Toncin Group Co., Ltd. offers vacuum filtration systems designed for optimal performance in dewatering applications. Their vacuum filters provide excellent separation, even for the most challenging mixtures.

Rotary drum filters use a rotating drum covered with filter cloth. As the drum rotates, the slurry is spread evenly over the filter surface. The liquid passes through the filter cloth, leaving the solid particles behind. Rotary drum filters are ideal for large-scale operations that require continuous solid-liquid separation.

Rotary drum filters are widely used in the mining, chemical, and food processing industries.

● Continuous operation: These filters are designed to operate continuously, making them ideal for high-volume operations.

● Low maintenance: The design of rotary drum filters allows for easy maintenance and low downtime.

● High throughput: Rotary drum filters can handle large volumes of material, making them suitable for industries with high demands.

Product Example: Yantai Toncin’s rotary drum filters are designed for large-scale operations and provide high throughput with minimal energy consumption. They are perfect for industries that require continuous solid-liquid separation.

Membrane filtration is a technique that involves forcing a liquid through a semi-permeable membrane to separate solid particles. This technique is highly efficient and is often used in water purification, food production, and biotechnology industries.

● High separation efficiency: Membrane filtration is highly effective at removing fine solids and contaminants from liquids.

● Energy-efficient: This process requires less energy compared to traditional separation techniques like centrifugation.

● Compact: Membrane filtration systems are compact and can be easily integrated into existing operations.

Product Example: Nuclear Industry Yantai Toncin Group Co., Ltd. offers membrane filtration solutions that can be used in various industries for high-efficiency solid-liquid separation.

Nuclear Industry Yantai Toncin Group Co., Ltd. is a leader in the design and manufacture of solid-liquid separation equipment. With a focus on innovation, quality, and efficiency, Toncin’s products are used across various industries, including water treatment, pharmaceuticals, food and beverage, and mining.

● High performance: Toncin’s separation equipment is designed for optimal performance, ensuring maximum separation efficiency.

● Customization: Toncin offers tailored solutions that can be customized to meet the specific needs of different industries.

● Energy efficiency: Their equipment is designed to minimize energy consumption while delivering high throughput.

● Durability: Toncin’s products are built to last, ensuring long-term reliability and reduced downtime.

As industries strive for greater efficiency and sustainability, new trends in solid-liquid separation technologies are emerging. These trends include:

Automation is transforming the way solid-liquid separation is performed. By integrating sensors and real-time monitoring systems, separation processes can be optimized to improve efficiency, reduce waste, and minimize energy consumption. Companies like Yantai Toncin are leading the charge by incorporating automated features in their equipment.

There is a growing demand for energy-efficient separation technologies, particularly in industries where high volumes of material need to be processed. Advanced centrifuges, filter presses, and membrane filtration systems are being designed with energy-saving features to meet these demands.

Sustainability is becoming a critical factor in solid-liquid separation. Many companies are focused on developing technologies that reduce waste generation, recycle materials, and minimize environmental impact. Yantai Toncin is committed to providing environmentally friendly solutions that help businesses meet sustainability goals.

The best machine depends on the specific application. For fine particles, a centrifuge is highly effective, while filter presses are great for large volumes. Vacuum filters and rotary drum filters are also commonly used for continuous separation processes.

A centrifuge works by spinning the mixture at high speeds, creating centrifugal force. This force causes the denser solid particles to move outward, while the lighter liquid stays near the center.

Membrane filtration is ideal for fine particles and is commonly used in water purification and food production. However, it may not be suitable for all types of mixtures, especially those with large or dense solids.

Yantai Toncin offers high-performance, energy-efficient, and durable separation equipment that can be customized for a wide range of applications. Their equipment is designed to optimize efficiency, reduce waste, and improve product quality.

Solid-liquid separation is a crucial process in numerous industries, and selecting the right equipment can significantly impact the efficiency and quality of the operation. Whether you’re dealing with fine particles, large volumes, or challenging mixtures, machines like centrifuges, filter presses, and rotary drum filters can help achieve optimal separation.

Nuclear Industry Yantai Toncin Group Co., Ltd. provides top-of-the-line solid-liquid separation solutions that are tailored to meet the unique needs of various industries. With a focus on performance, energy efficiency, and sustainability, Toncin is a trusted partner for businesses looking to improve their separation processes.

For more information on solid-liquid separation solutions, visit Nuclear Industry Yantai Toncin Group Co., Ltd. or contact us to discuss your specific needs.