Continuous Centrifuge It belongs to vertical type centrifugally-discharging screen filter diversion machine which has one complete set of diversion device to effectively adjust period of materials in the machine so that content of solid materials will be lowest with good effect on materials with 40μm.

| Availability: | |

|---|---|

| Quantity: | |

LXD

Toncin

Product Introduction:

The LXD Continuous Centrifuge is a vertically oriented, centrifugally-discharging screening and filtration machine equipped with an integrated diversion system. This system allows precise adjustment of material retention time, ensuring minimal solid content and optimal processing efficiency—especially effective for materials with particles as fine as 40μm.

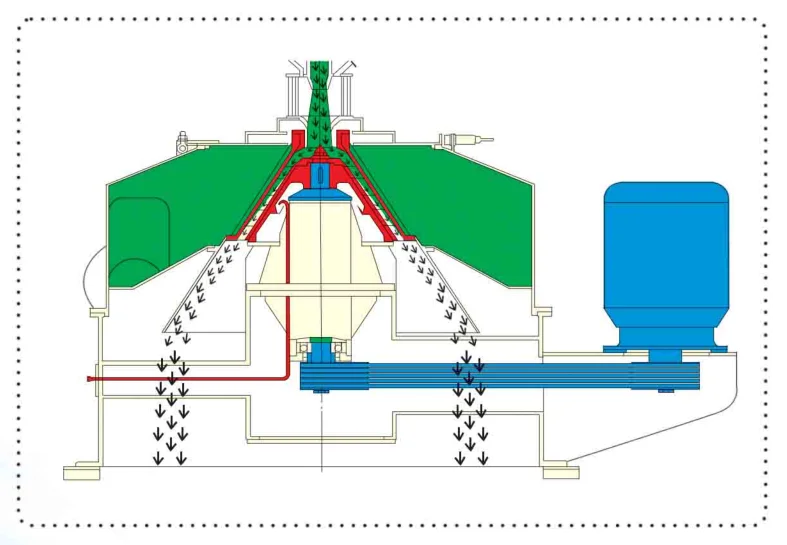

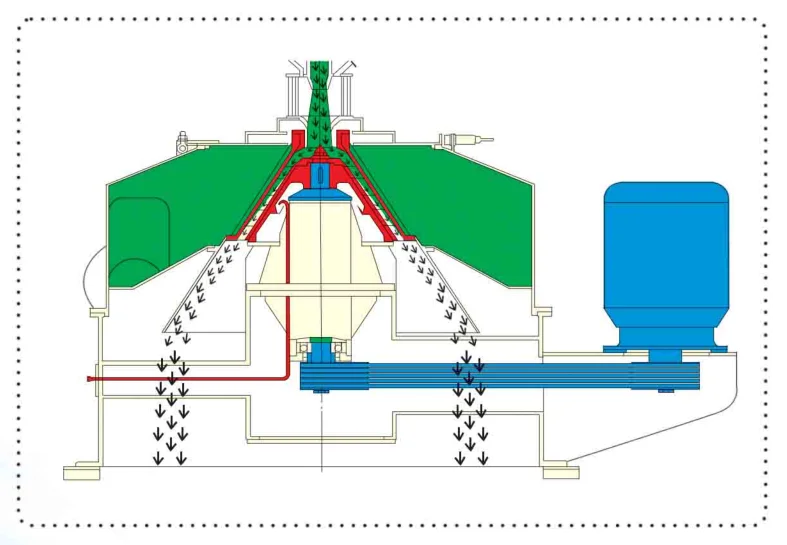

Material is fed into the centrifuge from the top and distributed into the diversion channels. Under centrifugal force, the slurry flows downward along the channels. During this process, liquid phase passes through the screen into the collection sump, while solid particles are conveyed along the channel walls and discharged into the lower solids chamber.

By leveraging centrifugal force, the LXD centrifuge simultaneously performs continuous filtration and discharge. The angle of the diversion channels can be freely adjusted to alter the flow path length and material residence time, enabling precise control over the solid moisture content and ensuring optimal dewatering performance.

Product Structure:

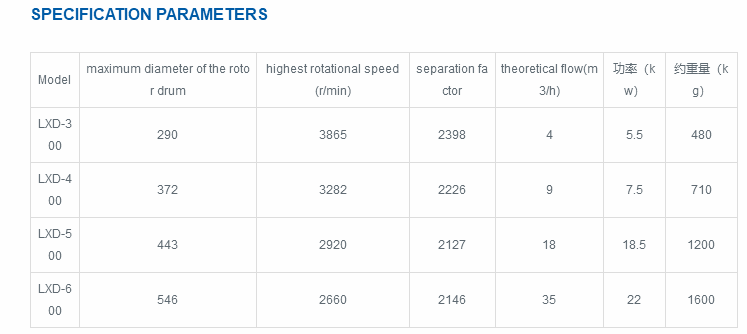

Product Specifications:

Product Characteristics:

No mechanical scrapers required — discharge is achieved through a combination of gravity and centrifugal force, ensuring crystal granules remain unbroken.

Featuring a vertical design, the centrifuge is easy to install, operates stably, and requires minimal maintenance.

The screen is designed for quick replacement and offers extended service life.

With low energy consumption and quiet operation, the system eliminates the need for complex shock-absorbing foundations.

An airtight sealing mechanism effectively contains organic solvents and materials with strong odors.

Order with requirement:

1. Anti-explosive design

2. Heat Preservation of outer casing

3. Special materials, such as Ti, Ti-Pd alloy, Ti-molybdenum alloy, etc.

4. Slag cleaning device

5. Frequency speed controller

6. Other special plans.

Product Advantages:

Without scraper, discharging with gravity and centrifugal force without destroying crystalline particles.

Vertical structure, simple installation, smooth operation, low failure rate, easy to replace the filter and long service life

Low power consumption, low operation noise

Not require complicated earthquake prevention foundation

Closed design, effective sealing of organic solvents or odor materials

Service Support:

Toncin develops optimal solutions by performing a systematic series of laboratory tests, semi-industrial trials, and theoretical analyses tailored to the specific challenges faced by each customer. Detailed technical parameters are determined through rigorous experimental validation at both lab and pilot scales.

With a robust project management system and an experienced technical team, Toncin delivers integrated engineering services tailored to customer needs. We ensure the successful achievement of project objectives through comprehensive management of quality, schedule, safety, cost, procurement, documentation, and coordination—in full compliance with contractual requirements.

Depending on the scope, Toncin undertakes design, procurement, construction, and commissioning for either full turnkey projects or specific phases, assuming full responsibility for quality, safety, timelines, and budget.

Response Time and After-sales Services

If any failure due to a defect has occurred during the warranty period, our company has given the following response and promise: to respond within 12 hours and rush to the domestic scene within 72 hours. With a rigorous and efficient service architecture, diverse and flexible service and response means, Toncin is capable of providing response service up to 7* 24 hours to ensure that users can get help at any time during the warranty period.

Product Introduction:

The LXD Continuous Centrifuge is a vertically oriented, centrifugally-discharging screening and filtration machine equipped with an integrated diversion system. This system allows precise adjustment of material retention time, ensuring minimal solid content and optimal processing efficiency—especially effective for materials with particles as fine as 40μm.

Material is fed into the centrifuge from the top and distributed into the diversion channels. Under centrifugal force, the slurry flows downward along the channels. During this process, liquid phase passes through the screen into the collection sump, while solid particles are conveyed along the channel walls and discharged into the lower solids chamber.

By leveraging centrifugal force, the LXD centrifuge simultaneously performs continuous filtration and discharge. The angle of the diversion channels can be freely adjusted to alter the flow path length and material residence time, enabling precise control over the solid moisture content and ensuring optimal dewatering performance.

Product Structure:

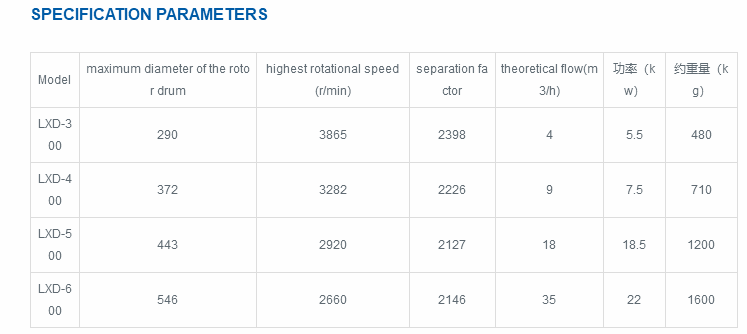

Product Specifications:

Product Characteristics:

No mechanical scrapers required — discharge is achieved through a combination of gravity and centrifugal force, ensuring crystal granules remain unbroken.

Featuring a vertical design, the centrifuge is easy to install, operates stably, and requires minimal maintenance.

The screen is designed for quick replacement and offers extended service life.

With low energy consumption and quiet operation, the system eliminates the need for complex shock-absorbing foundations.

An airtight sealing mechanism effectively contains organic solvents and materials with strong odors.

Order with requirement:

1. Anti-explosive design

2. Heat Preservation of outer casing

3. Special materials, such as Ti, Ti-Pd alloy, Ti-molybdenum alloy, etc.

4. Slag cleaning device

5. Frequency speed controller

6. Other special plans.

Product Advantages:

Without scraper, discharging with gravity and centrifugal force without destroying crystalline particles.

Vertical structure, simple installation, smooth operation, low failure rate, easy to replace the filter and long service life

Low power consumption, low operation noise

Not require complicated earthquake prevention foundation

Closed design, effective sealing of organic solvents or odor materials

Service Support:

Toncin develops optimal solutions by performing a systematic series of laboratory tests, semi-industrial trials, and theoretical analyses tailored to the specific challenges faced by each customer. Detailed technical parameters are determined through rigorous experimental validation at both lab and pilot scales.

With a robust project management system and an experienced technical team, Toncin delivers integrated engineering services tailored to customer needs. We ensure the successful achievement of project objectives through comprehensive management of quality, schedule, safety, cost, procurement, documentation, and coordination—in full compliance with contractual requirements.

Depending on the scope, Toncin undertakes design, procurement, construction, and commissioning for either full turnkey projects or specific phases, assuming full responsibility for quality, safety, timelines, and budget.

Response Time and After-sales Services

If any failure due to a defect has occurred during the warranty period, our company has given the following response and promise: to respond within 12 hours and rush to the domestic scene within 72 hours. With a rigorous and efficient service architecture, diverse and flexible service and response means, Toncin is capable of providing response service up to 7* 24 hours to ensure that users can get help at any time during the warranty period.