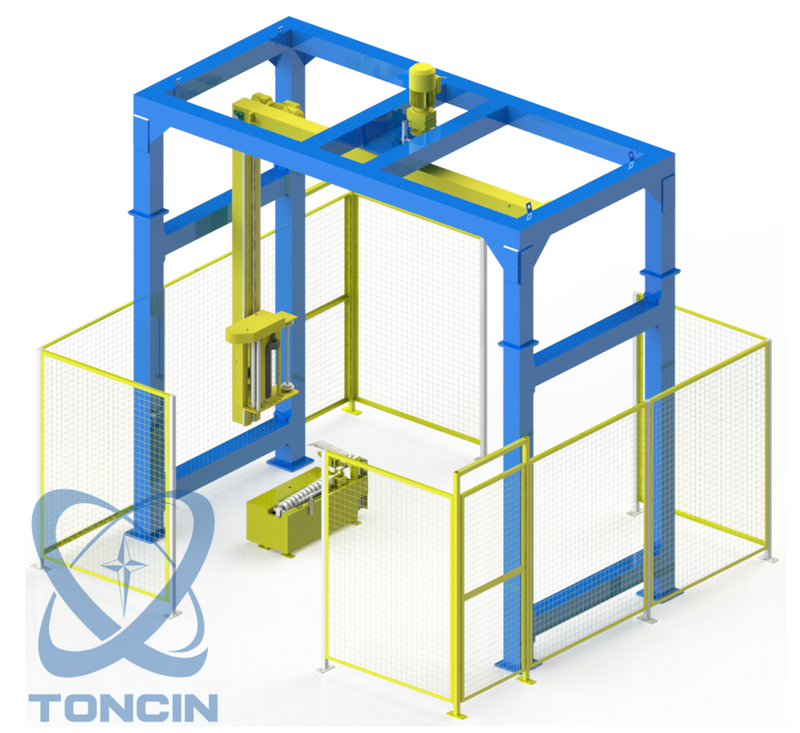

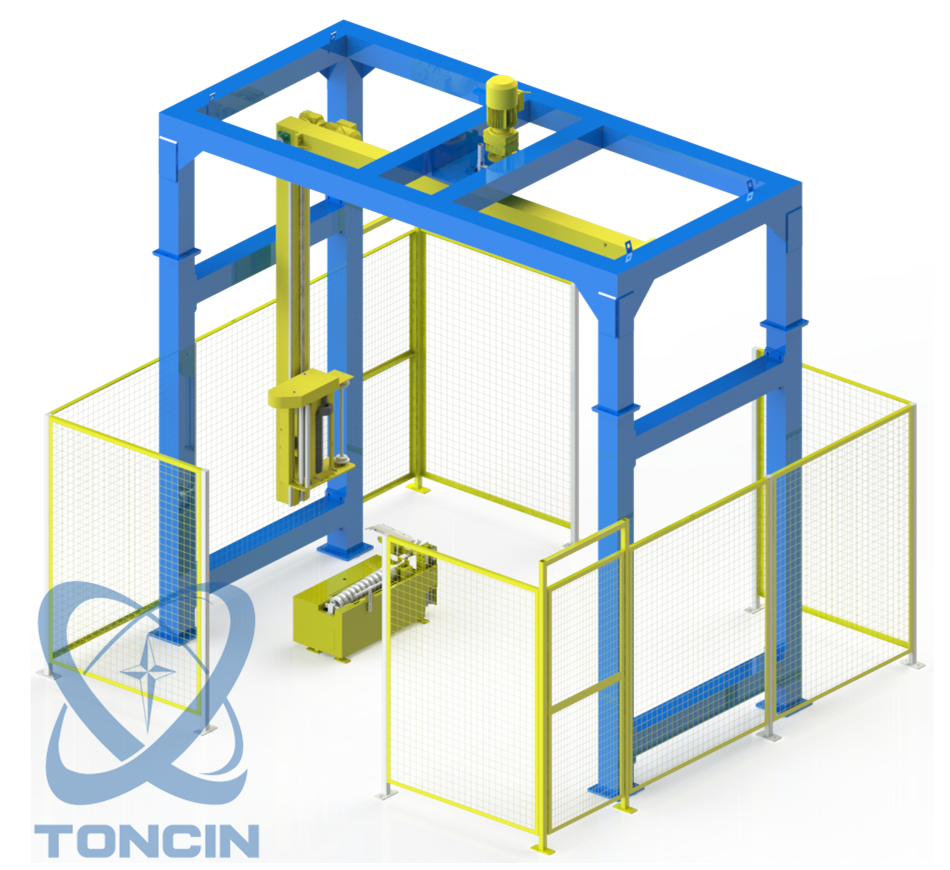

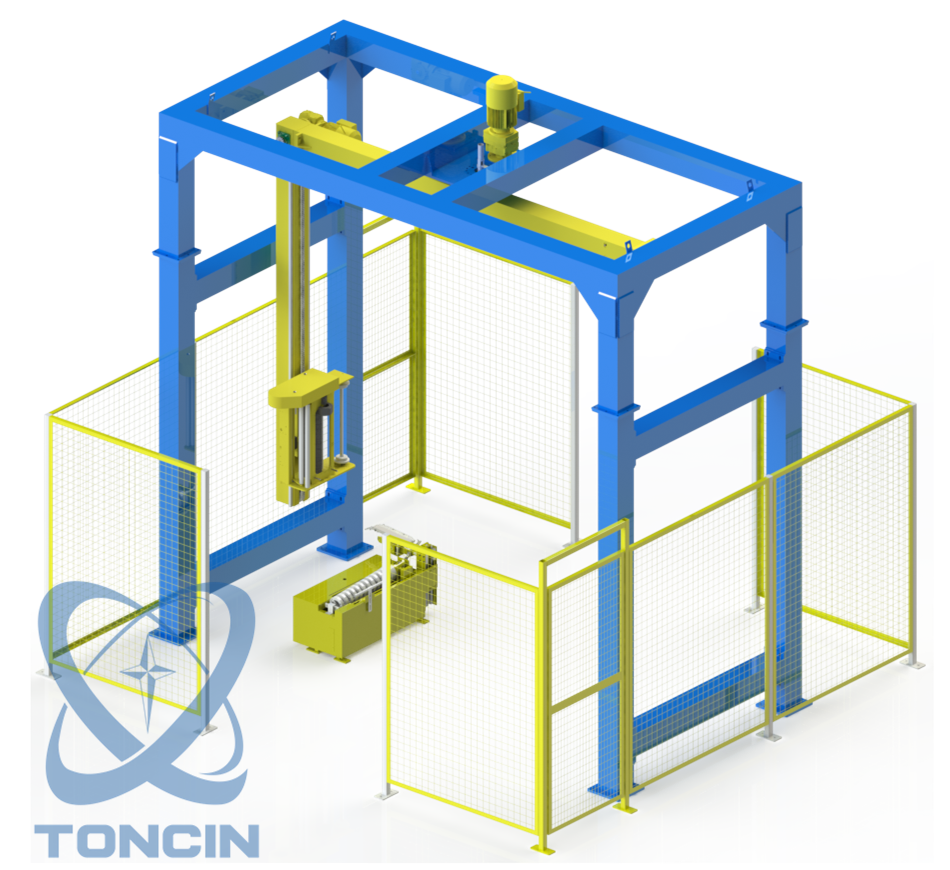

Automatic Stretch Wrapping Machinery

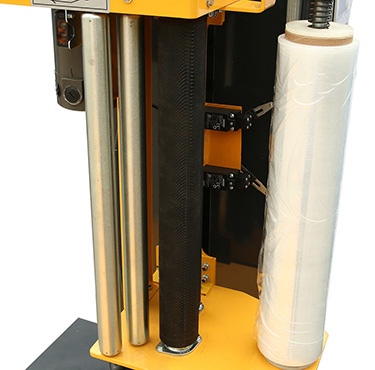

DR series fully automatic rotary arm stretch wrapper .it is suitable for the big volume, high efficiency factory and applied on different dimensions goods. Can be customized according to customer demand, can work with production and assembly line together and used for wrapping separately. The machine could complete the process for goods' sensing, centering, conveying and wrapping, the conveyor could be customized as per customer site. Fully automatic structure could be zero-labor, it is the high efficiency modern type, widely used in food, beverage, chemical, paper making, building material and other industries

DR1800FZ-FM,this model add top sheet function and is new all in one wrapper machine.it is with stretch wrapping and top sheet functions, it could do 5 sides wrapping ,dust-proof, moisture-proof, rain-proof. It realized zero-labor function, high efficiency and cost saving.

English

English