| Availability: | |

|---|---|

| Quantity: | |

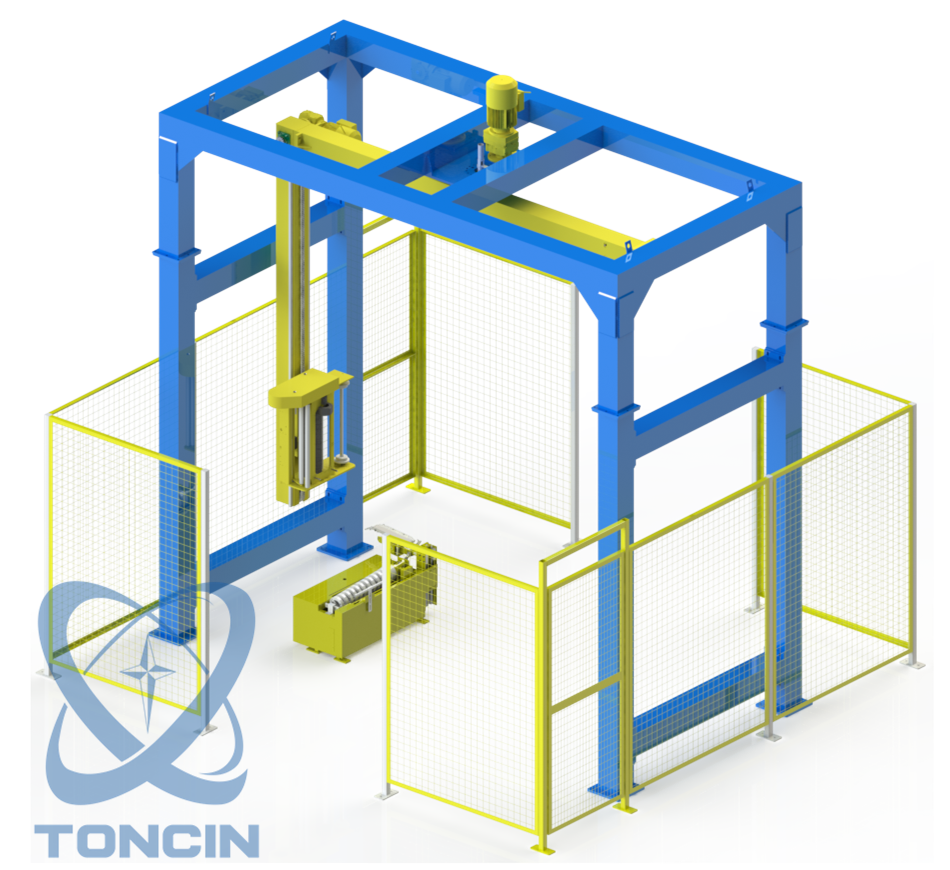

DR1800FZ-H

TONCIN

This machine is stretch wrap system that can operate in-line with other automatic equipment. The pallet is auto travelled to the pallet wrapper from the inbound conveyer. Wrapping cycle automatically begins when the pallet is placed in the wrapping position. Film attached against the pallet at the beginning of the wrap then cut&grab the end of the film after wrapping finished. The wrapped pallet is moved to the outbound conveyer ready for unload. And the machine is ready for the next load.

Introducing the DR1800FZ-FM model, an innovative all-in-one wrapper with added top sheet functionality. This machine combines stretch wrapping and top sheet features, allowing for 5-sided wrapping that ensures dust-proof, moisture-proof, and rain-proof protection. With its zero-labor capability, high efficiency, and cost-saving benefits, it stands out as a versatile solution for various industries.

Technical Parameter:

Wrapping size | (500-1200)*(500-1200)*2200(L*W*H) |

Rotary arm speed | 0-20RPM, adjustable |

Wrapping efficiency | >25pallet/hour |

Film carriage system | Pre stretch,>250%, speed adjustable |

Film cutting clamping | Automatic film cutting claming |

Top sheeter film | PE/PVA film, width:1800mm, diameter:100-300um, thickness: 30-100um |

Wrapping flim | LLDPE width:500mm, thickness:20-35um |

Lifter part | Rail lift system speed adjustable |

Conveyor system | Conveyor height:400mm, speed:8-15m/min, bearing weight: 2000kg |

Control system | PLC, parameters adjustable, length of laminating film adjustable, sense product height automatically |

Motor | Rotary arm:1.1 kw, film carriage: 0.37kw, lifter: 0.37kw, top sheeter: 0.37kw |

Power | 380V, 50HZ, 3фаза, 4kw |

Pneumatic | 0.4-0.6Mpa, 35NL/min |

Dimension | 4500*2200*3500mm |

Component | Four heavy duty column,rotary arm system, top sheeter, automatic film cutting clamping, conveyor |

Rotary Arm System

1.1) Inverter for motor speed adjustment.

1.2) Rotary arm equipped with a guide device.

1.3) Two fixed spacing blocks and a moving limit block at both ends of the rotary arm.

Film Carriage System

2.1) Chain transmission for stable and highly reliable film carriage lifting.

2.2) Film Tension Control adjustment on the panel.

2.3) Separate DC Drive Motor for variable speed film delivery.

2.4) Auto Film Feeding and Cutting System.

2.5) Pre-stretch carriage.

Control System

3.1) OMRON PLC.

3.2) LED panel.

3.3) Adjustable twisted layers and frequency settings.

3.4) Powered pre-stretch system, stretching film up to 250% to minimize film consumption.

3.5) Photo-eye pallet height sensor.

3.6) Automatic load detection and initiation of wrapping.

3.7) Photoeye sensing delay.

3.8) Chain transmission for accurate positioning.

Rack System

4.1) Four brackets (sprayed with carbon steel finish) for enhanced machine stability.

4.2) Transmission mechanism at the upper part of the frame.

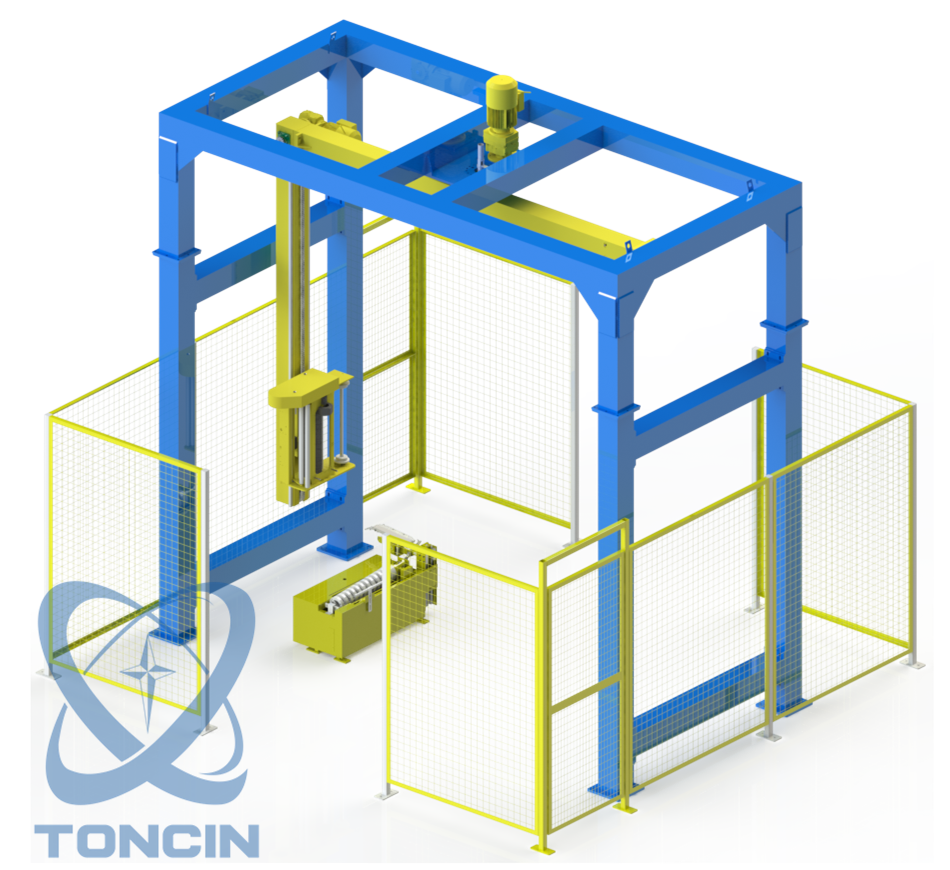

This machine is stretch wrap system that can operate in-line with other automatic equipment. The pallet is auto travelled to the pallet wrapper from the inbound conveyer. Wrapping cycle automatically begins when the pallet is placed in the wrapping position. Film attached against the pallet at the beginning of the wrap then cut&grab the end of the film after wrapping finished. The wrapped pallet is moved to the outbound conveyer ready for unload. And the machine is ready for the next load.

Introducing the DR1800FZ-FM model, an innovative all-in-one wrapper with added top sheet functionality. This machine combines stretch wrapping and top sheet features, allowing for 5-sided wrapping that ensures dust-proof, moisture-proof, and rain-proof protection. With its zero-labor capability, high efficiency, and cost-saving benefits, it stands out as a versatile solution for various industries.

Technical Parameter:

Wrapping size | (500-1200)*(500-1200)*2200(L*W*H) |

Rotary arm speed | 0-20RPM, adjustable |

Wrapping efficiency | >25pallet/hour |

Film carriage system | Pre stretch,>250%, speed adjustable |

Film cutting clamping | Automatic film cutting claming |

Top sheeter film | PE/PVA film, width:1800mm, diameter:100-300um, thickness: 30-100um |

Wrapping flim | LLDPE width:500mm, thickness:20-35um |

Lifter part | Rail lift system speed adjustable |

Conveyor system | Conveyor height:400mm, speed:8-15m/min, bearing weight: 2000kg |

Control system | PLC, parameters adjustable, length of laminating film adjustable, sense product height automatically |

Motor | Rotary arm:1.1 kw, film carriage: 0.37kw, lifter: 0.37kw, top sheeter: 0.37kw |

Power | 380V, 50HZ, 3фаза, 4kw |

Pneumatic | 0.4-0.6Mpa, 35NL/min |

Dimension | 4500*2200*3500mm |

Component | Four heavy duty column,rotary arm system, top sheeter, automatic film cutting clamping, conveyor |

Rotary Arm System

1.1) Inverter for motor speed adjustment.

1.2) Rotary arm equipped with a guide device.

1.3) Two fixed spacing blocks and a moving limit block at both ends of the rotary arm.

Film Carriage System

2.1) Chain transmission for stable and highly reliable film carriage lifting.

2.2) Film Tension Control adjustment on the panel.

2.3) Separate DC Drive Motor for variable speed film delivery.

2.4) Auto Film Feeding and Cutting System.

2.5) Pre-stretch carriage.

Control System

3.1) OMRON PLC.

3.2) LED panel.

3.3) Adjustable twisted layers and frequency settings.

3.4) Powered pre-stretch system, stretching film up to 250% to minimize film consumption.

3.5) Photo-eye pallet height sensor.

3.6) Automatic load detection and initiation of wrapping.

3.7) Photoeye sensing delay.

3.8) Chain transmission for accurate positioning.

Rack System

4.1) Four brackets (sprayed with carbon steel finish) for enhanced machine stability.

4.2) Transmission mechanism at the upper part of the frame.