Product Introduction

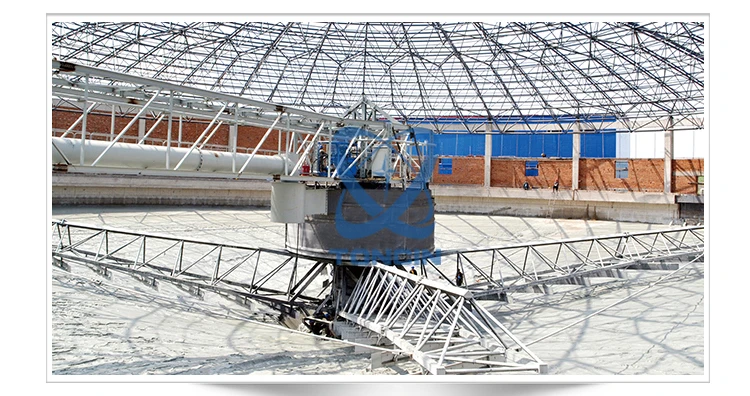

The GNZ centre drive efficient thickener represents a novel solid-liquid separation equipment designed by our company, incorporating advanced foreign technology. This thickener boasts several national patents, including center drive, high-efficiency feeding hopper, and automatic rake lifting technology. Its heavy-duty core design ensures reliable operation even in challenging conditions, significantly enhancing concentration efficiency.

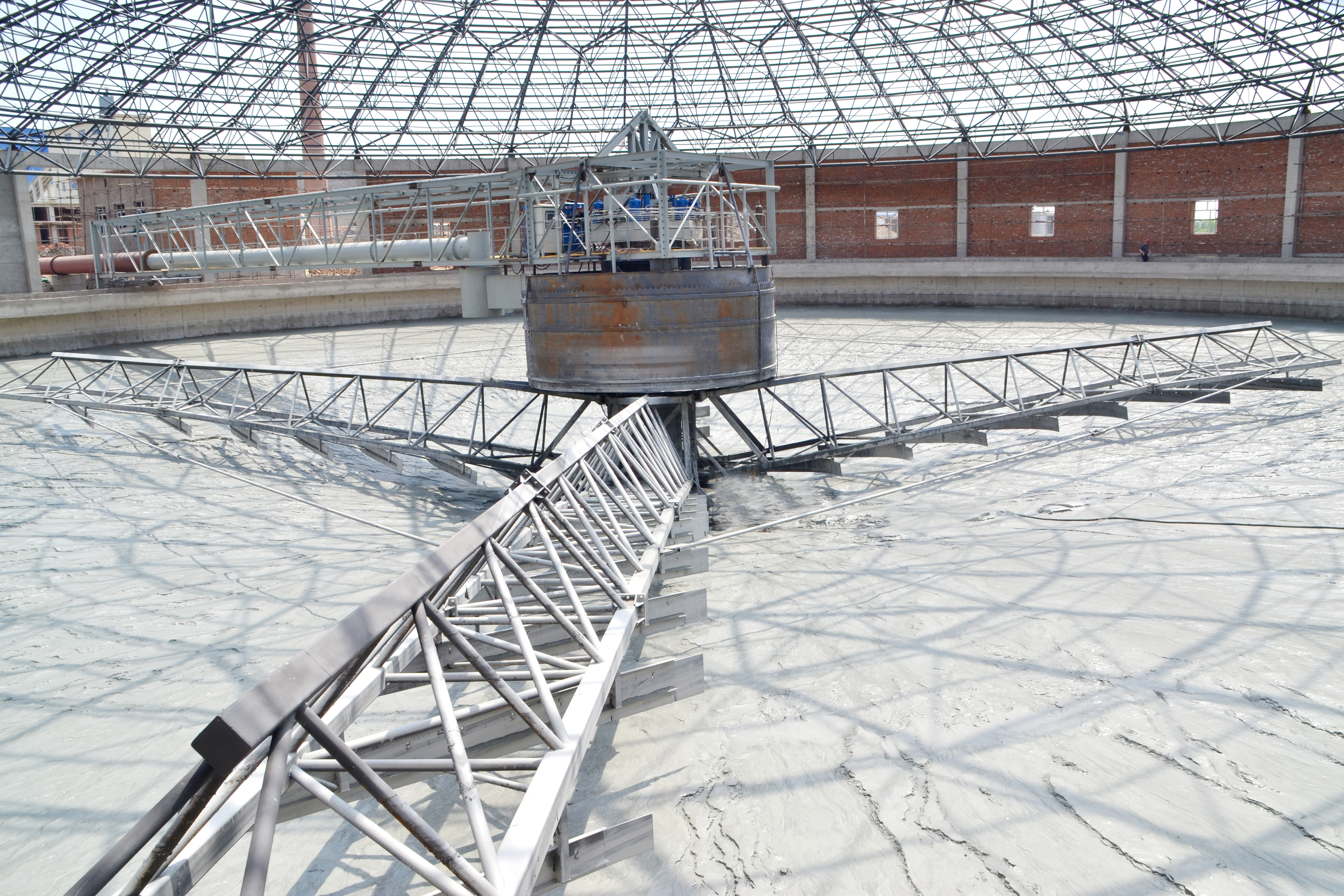

The GNZ high-efficient thickener achieves effective dewatering through the gravitational action of the material itself and flocculating settlement. In the feed tank, the slurry is mixed with a flocculating agent and directed to the high-efficiency feed hopper, also known as the steady flow tank. Following degassing and energy dissipation in the steady flow tank, the material proceeds along the horizontal tangent of the inner tank, which features multiple flocculent adding points based on material properties. After a second round of mixing and settling, the material and flocculating agent move downwards and are guided along a parabolic trajectory by the distributor disc at the tank's bottom. The settled material is then scraped by the rake towards the center throat of the pool body for centralized discharge.

Product Application

The GNZ thickener represents an innovative high-rate thickening solution featuring central-drive and automatic lifting rake, developed by integrating cutting-edge foreign technology. This advanced thickener finds wide-ranging applications in treating various industrial feed pulps, including coal, metal ore dressing water, metallurgy, chemical processes, tailings treatment, and environmental protection, among others.

Product Specifications

Model | Concentration tank | Sediment area

(m2) | The lifting height of rake(mm) | Rake rotating speed(r/min) | Motor Power

(KW) |

Diameter(m) | Depth(m) |

GNZ-3 | 3 | 2.5 | 10 | 300 | 0.1-0.2 | 3+1.1 |

GNZ-6 | 6 | 3.0 | 28 | 300 | 0.1-0.2 | 4+1.5 |

GNZ-9 | 9 | 3.2 | 63 | 300 | 0.1-0.2 | 4+1.5 |

GNZ-12 | 12 | 3.5 | 110 | 300 | 0.1-0.2 | 4+1.5 |

GNZ-18 | 18 | 4.4 | 254 | 600 | 0.1-0.2 | 7.5+2.2 |

GNZ-20 | 20 | 4.4 | 310 | 600 | 0.1-0.2 | 7.5+2.2 |

GNZ-24 | 24 | 5.2 | 452 | 600 | 0.05-0.2 | 7.5+2.2 |

GNZ-30 | 30 | 5.2 | 707 | 600 | 0.05-0.2 | 11+3 |

GNZ-38 | 38 | 5.5 | 1134 | 600 | 0.05-0.2 | 15+4 |

GNZ-45 | 45 | 5.5 | 1590 | 600 | 0.05-0.1 | 37+4 |

GNZ-53 | 53 | 6.0 | 2206 | 600 | 0.05-0.1 | 37+4 |

GNZ-60 | 60 | 6.0 | 2826 | 600 | 0.03-0.1 | 45+5.5 |

GNZ-70 | 70 | 6.8 | 3846 | 600 | 0.02-0.05 | 45+5.5 |

GNZ-85 | 85 | 7.8 | 5671 | 600 | 0.02-0.05 | 45+5.5 |

Note:

1. The above parameters are only for reference. As the settlement performance of materials is relatively large, the specific parameters are subject to the design drawings provided by our company.

2. Our company can design thickener with different models according to the requirements of users.

Product Advantages

The concentrating and scraping efficiency of our thickeners is significantly enhanced, ranging from three to five times that of conventional thickeners.

Our thickeners boast an outstanding Feeding System with an efficient steady flow tank.

The equipment is equipped with an ultra-heavy-duty drive lifting system and large torque designs, ensuring its normal operation even in the most extreme conditions.

The rake teeth feature a logarithmic spiral design, with teeth density tailored to the material's nature, providing optimal performance.

Product Features

This thickening system comprises a round thickener and a harrow scrapping machine. Solid particles suspended in the thickener settle by gravity, with the upper pulp transforming into clean water, facilitating effective separation. The harrow continuously discharges sedimented slime from the thickener's bottom, while clean overflow emerges from the top.

Key Features:

Exceptional concentration and scraping efficiency, surpassing common thickeners by three to five times.

Outstanding feed system – high-rate feed well: a. The feed well promotes degassing and energy dissipation with tangential feeding. b. Rational addition of flocculants enhances efficiency. c. Equipped with a distribution plate, effectively utilizing the tank's area.

Driven lifting system with an overweight and large torque design ensures continuous operation even in extreme conditions, enhancing overall efficiency.

Logarithmic spiral design of rake teeth, with adjustable density based on material performance, improves scraping efficiency.

Advanced thickener control system incorporates automatic lifting of the rake, flocculant feeding, and automated control of underflow discharge pump, streamlining operational processes for optimal efficiency.

Product Details

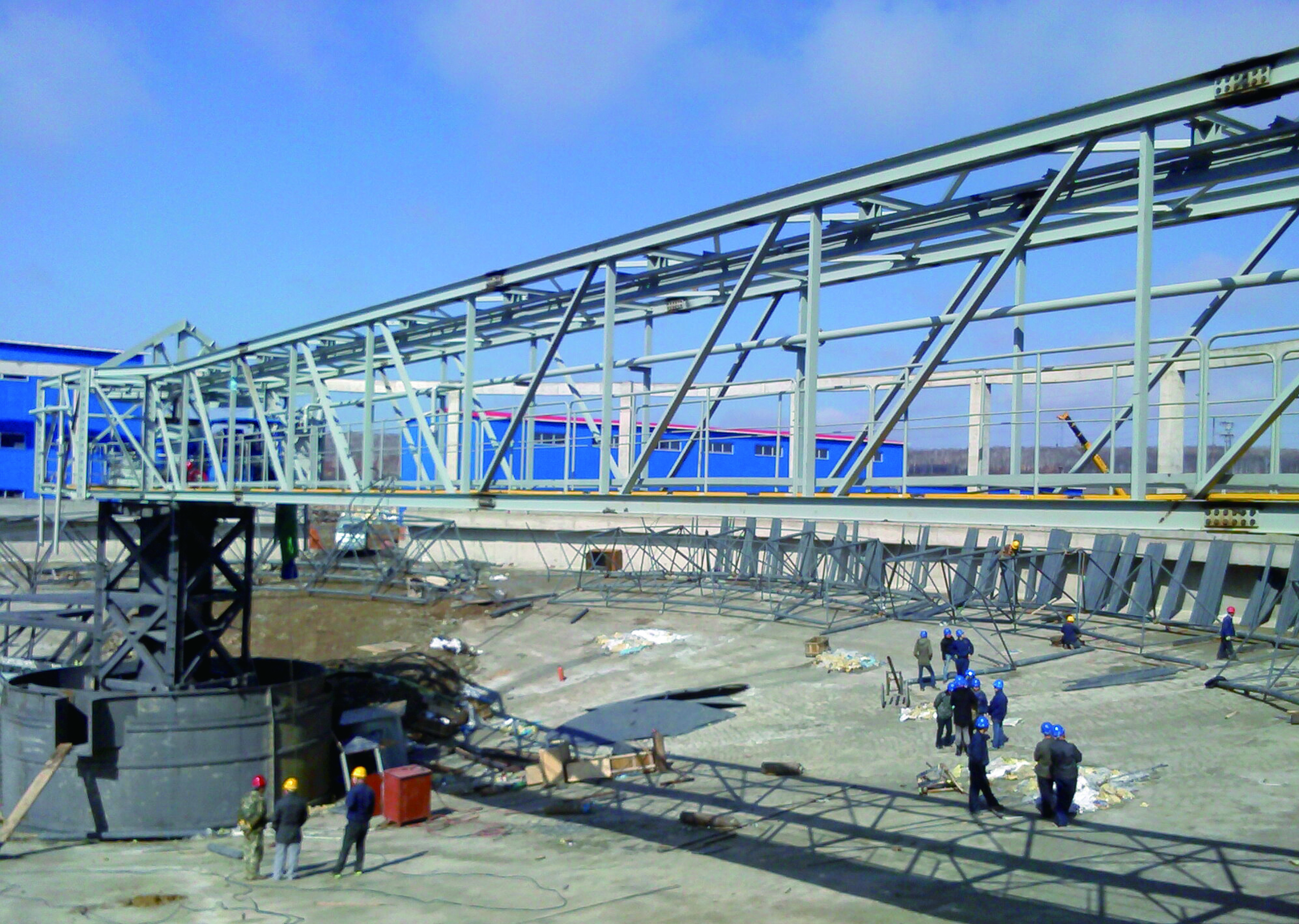

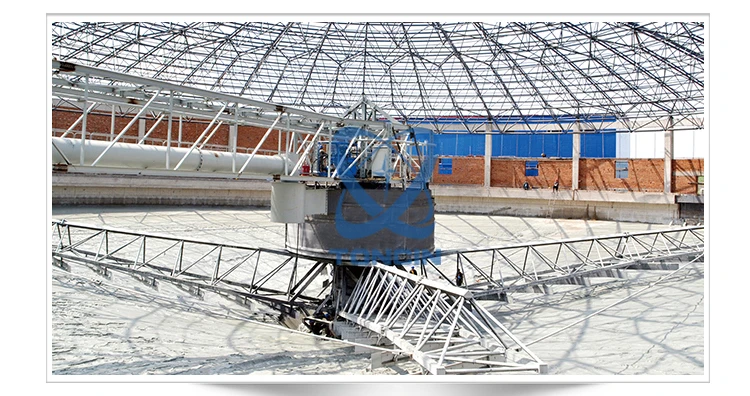

Design of Main Driving and Rake Lifting Mechanism

(1) The driving framework and chassis are constructed based on heavy-duty transmission device standards, ensuring stable and reliable operation.

(2) Full automatic rake lifting is incorporated for enhanced operational efficiency.

(3) Star transmission system is employed with a maximum running torque of 5000,000Nm. The designed torque of the driving transmission adheres to the following standards:

Running torque value: 33% of the designed torque.

High torque alarm: 50% of the designed torque.

Rake rising: 60% of the designed torque.

Rake decreasing: 40% of the designed torque.

The designed torque value of the mechanical device: 150% of the designed torque.

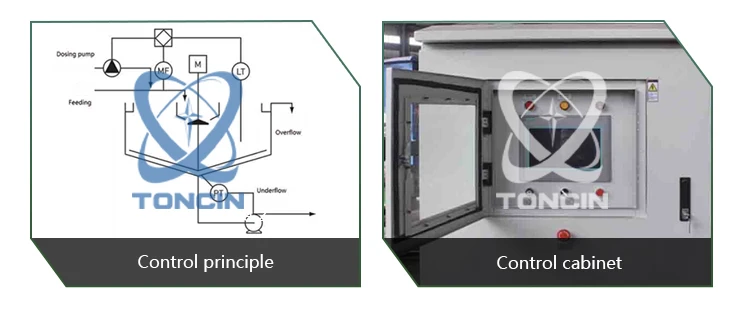

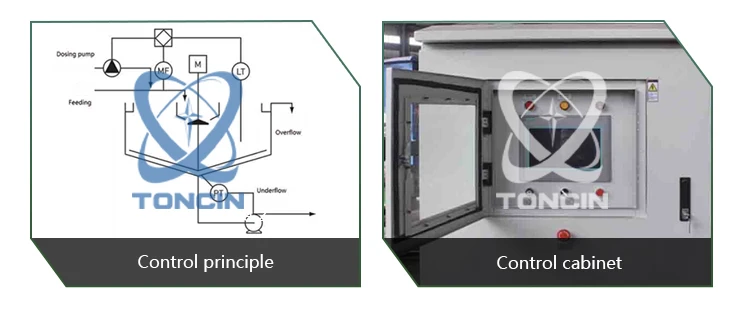

2. Control System

Site control and remote control are combined,DCS control points are supplied.

(1)PLC control,overloading protection.

(2)Material discharging terminal is set up with mud layer pressure sensor to control rotation and mud discharging by pump.

Service Support

Toncin formulates rational plans and selections by conducting thorough laboratory tests, semi-industrialization trials, and theoretical analysis calculations. The adoption of appropriate methods is tailored to address the specific challenges faced by customers. Specific parameters are determined through a combination of laboratory tests and semi-industrial trials.

Toncin offers customers integrated project services, leveraging its flawless project management system and a seasoned, high-quality team. We are committed to delivering our best services to achieve the ultimate project goal. This involves managing project quality, schedule, safety, cost, procurement, information files, organization, and coordination, all in accordance with the customer's contractual documents.

Toncin undertakes the design, procurement, construction, and trials for the entire process or specific stages of the construction project as per the contract. We assume full responsibility for the quality, safety, duration, and cost efficiency of the contracted project, ensuring a seamless and successful project outcome.

Response Time and After-sales Services

If any failure due to a defect has occurred during the warranty period, our company has given the following response and promise: to respond within 12 hours and rush to the domestic scene within 72 hours. With a rigorous and efficient service architecture, diverse and flexible service and response means, Toncin is capable of providing response service up to 7* 24 hours to ensure that users can get help at any time during the warranty period.

English

English