Company Introduction

Yantai Sunny Hexing Environment Protection Equipment Co.,Ltd.(Toncin Group’s branch) was founded in 2004, located in Yantai, Shandong province, with more than 200 employees, various professional production equipment and inspection and testing instruments.

After over a decade of progress, Sunny has emerged as an expert in the design, research and development, production, installation and technical support of solid-liquid separation. Our company has obtained ISO9001, ISO14001, OHSAS18001, and CE certifications.

As a leading domestic provider of solid-liquid separation machinery, we have successfully exported our products to over 20 countries including Europe, the United States, Southeast Asia, West Asia, and Africa. Our reputation in both domestic and international markets is highly regarded, and we have received widespread acclaim from our valued customers.

Sunny proudly holds the title of being the largest equipment supplier in China's FGD market. We maintain strong partnerships with the five major power groups in China as well as provincial power companies.

To date, we have completed well over a thousand FGD projects, with more than 2000 equipment units currently operational worldwide.

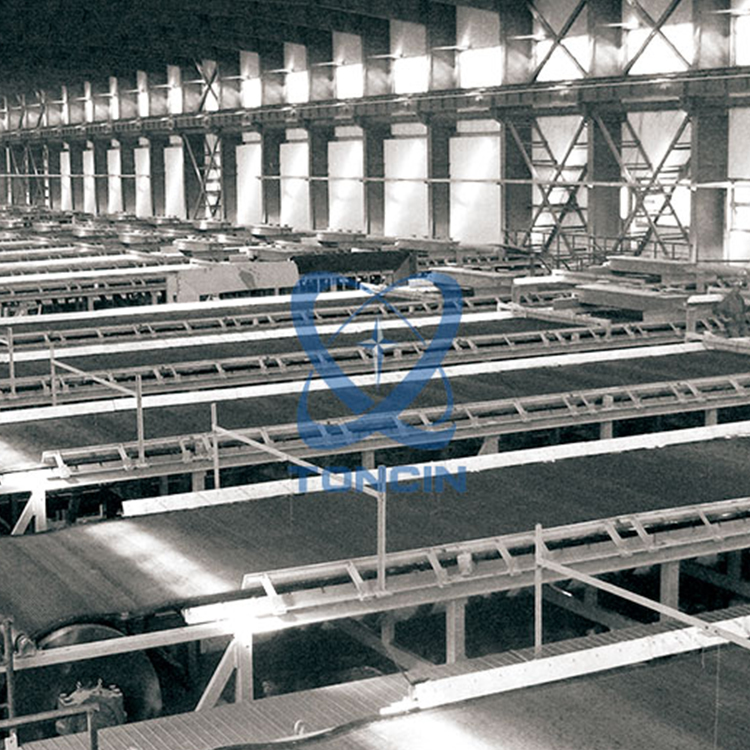

FGD Vacuum Belt Dehydrator

The FGD vacuum belt dehydrator, also known as the fixed vacuum chamber rubber belt filter, is an innovative and efficient mechanical equipment for separating solids and liquids. Our company developed this equipment by incorporating and adapting technologies from similar foreign products. This machine utilizes both gravity and vacuum suction to achieve effective solid-liquid separation. The vacuum zone is horizontally arranged, allowing for continuous use and various processes such as filtration, washing, and blotting. It offers numerous advantages, including high filtration efficiency, large production capacity, effective washing, versatile applications, easy operation, and convenient maintenance. It is particularly suitable for filtering suspension slurry with coarse solid particles, high density, and the need for multiple washes. This equipment finds wide applications in industries such as metallurgy, mining, chemical, papermaking, food, pharmaceuticals, and environmental protection. It excels in achieving optimal solid-liquid separation.

Product Advantages

- A water-sealed, lubricated, and cooled ring friction belt is placed between the vacuum box and the filter tape. This belt ensures a reliable vacuum seal, maintaining stability, reducing moisture in the filter cake, and promoting stable operation. Additionally, the ring friction belt has low friction, a long lifespan, and can be easily and quickly replaced.

- The tape is supported by either an air cushion, water film, or encrypted roller support. This support allows the tape to float on a pad, reducing resistance and extending its lifespan.

- A circular filter tape with high tensile strength and a long lifespan is used.

- The overall structure is designed with modularity in mind, allowing for flexible assembly, easy transportation, and installation.

- An airbag-type automatic filter cloth correction device is included to ensure the stable operation of the filter cloth.

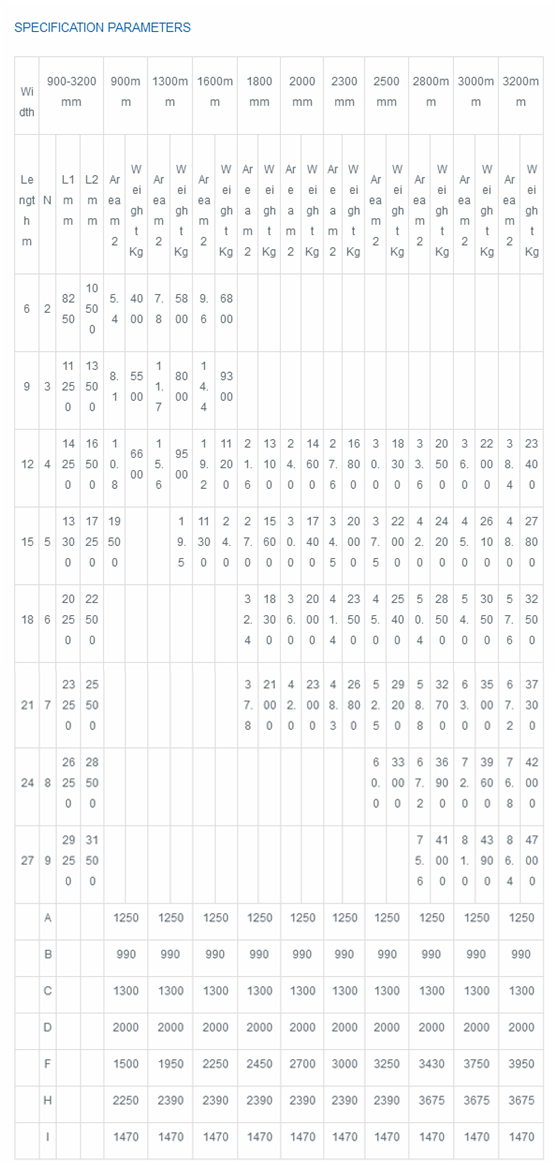

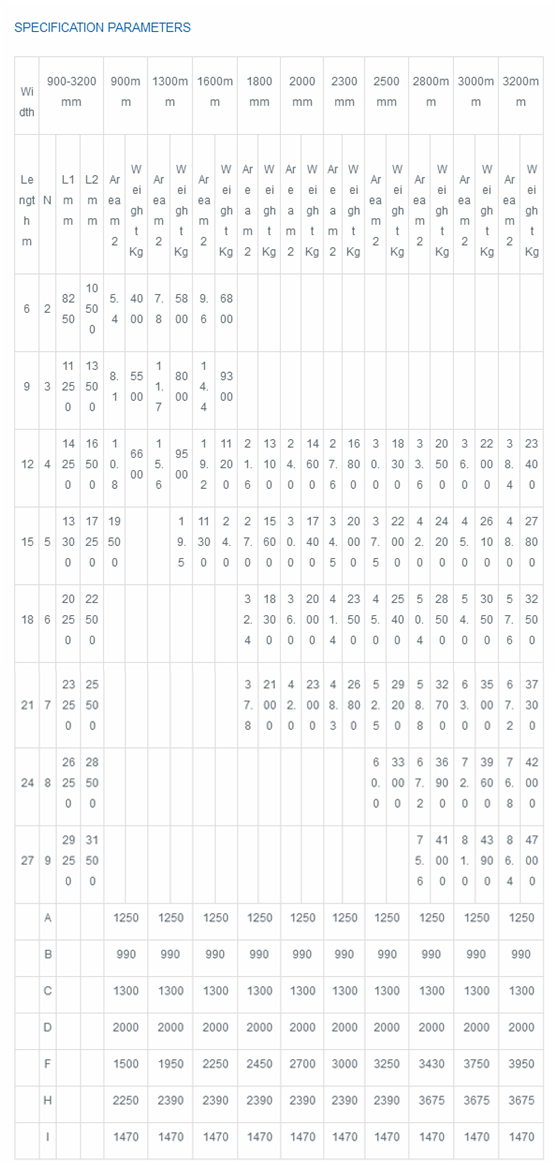

Product Specification

Service Support

Whole Technological Design

Toncin determines reasonable plans and selections by conducting more systematic laboratory tests, semi-industrialization tests and theoretical analysis calculations and adopting appropriate methods in light of the actual problems faced by customers. And it determines specific parameters through laboratory tests and semi-industrial tests.

Project Construction

Toncin can provide customers with integrated project services for its perfect project management system and experienced high-quality team and can also provide customers with its best services in achieving the ultimate project goal by carrying out the management work on the project quality, schedule, safety, cost, procurement, information files, organization and coordination etc. according to customer’s contractual documents. Toncin contracts the design, procurement, construction and trials etc. for the entire process or some certain stages of the construction project according to the contract and takes full liability for the quality, safety, duration and cost etc. of the contracted project.

Response Time and After-sales Services

If any failure due to a defect has occurred during the warranty period, our company has given the following response and promise: to respond within 12 hours and rush to the domestic scene within 72 hours. With a rigorous and efficient service architecture, diverse and flexible service and response means, Toncin is capable of providing response service up to 7* 24 hours to ensure that users can get help at any time during the warranty period.

Item | Project or Power Plant | Capacity | Belt filter type | Gypsum capacity/hour | Equipment quantity | Sign date |

No. |

1 | Sudan Khartoum Power Station Co., Ltd. | 2×100MW | DU-10.0m²/1000 | 9820.00kg | 2sets | 2007.07.09 |

2 | India Jhajjar Power Generation plant | 2×660MW | DU11.7M2/1300 | 10470.00kg | 2sets | 2009.12.21 |

3 | Inidia IL&FS Cuddalore FGD project | N/A | DU45M2/3000 | 38 tons | 2sets | 2014.04 |

4 | Pakistan Qasim Port Generation power plant | 2×660MW | DU57.0M2/3000 | 48450.00kg | 2sets | 2015.12 |

5 | Pakistan Sahiwal Power plant | 2×660MW | DU27.5M2/2500 | 22550.00kg | 2sets | 2015.12 |

6 | Serbia KOSTOLAC-B I stage FGD project | N/A | DU48M2/2800 | 40800.00 kg | 2sets | 2013.08 |

7 | Turkey Power Station Co., Ltd.II | 2×660MW | DU-28.0m²/2000 | 23800.00kg | 2sets | 2008.04.02 |

8 | Indonesia TJB Coal Power Station Co., Ltd. | 2×660MW | DU-11.7m²/1300 | 10200.00 kg | 2sets | 2007.10 |

9 | Laos Hongsa Power Plant | 3x626MW | DU48 m²/3000 | 45560.00KG | 3sets | 2012.09 |

10 | Vietnam Hejing Power Plant | N/A | DU-16.9m²/1300 | 14070.00 | 2sets | 2013.04 |

11 | Vietnam Haiphong Power Plant Phase II 2X300MW FGD Project | 2X300MW | DU17M2/1300 | Around 15 tons | 1 set | 2011.9.22 |

12 | Russia Troitsk National Power Station 2X660MW Power Generating Construction FGD Project | 2X660MW | DU-15.6M2/1300 | Around 14 tons | 2 sets | 2011.10.20 |

13 | India Rubamin Self-generation power plant FGD | N/A | DU4.2m2/1200 | 3ton | 1set | 2018.03.01 |

14 | India NTPC Jhajjar Power Generation plant | NTPC | DU54/3200 | 48 | 2sets | 2018.05.01 |

15 | India NTPC Dadri power plant FGD | NTPC | DU35/2500 | 32 | 2sets | 2018.07 |

16 | NTPC-Kudgi&Gadarwara | 3×800MW/2×800MW | DU-72m²/3200 DU-48m²/3000 | 71800/47900kgs | 4sets | 2019.5.13 |

English

English