Products Introduction:

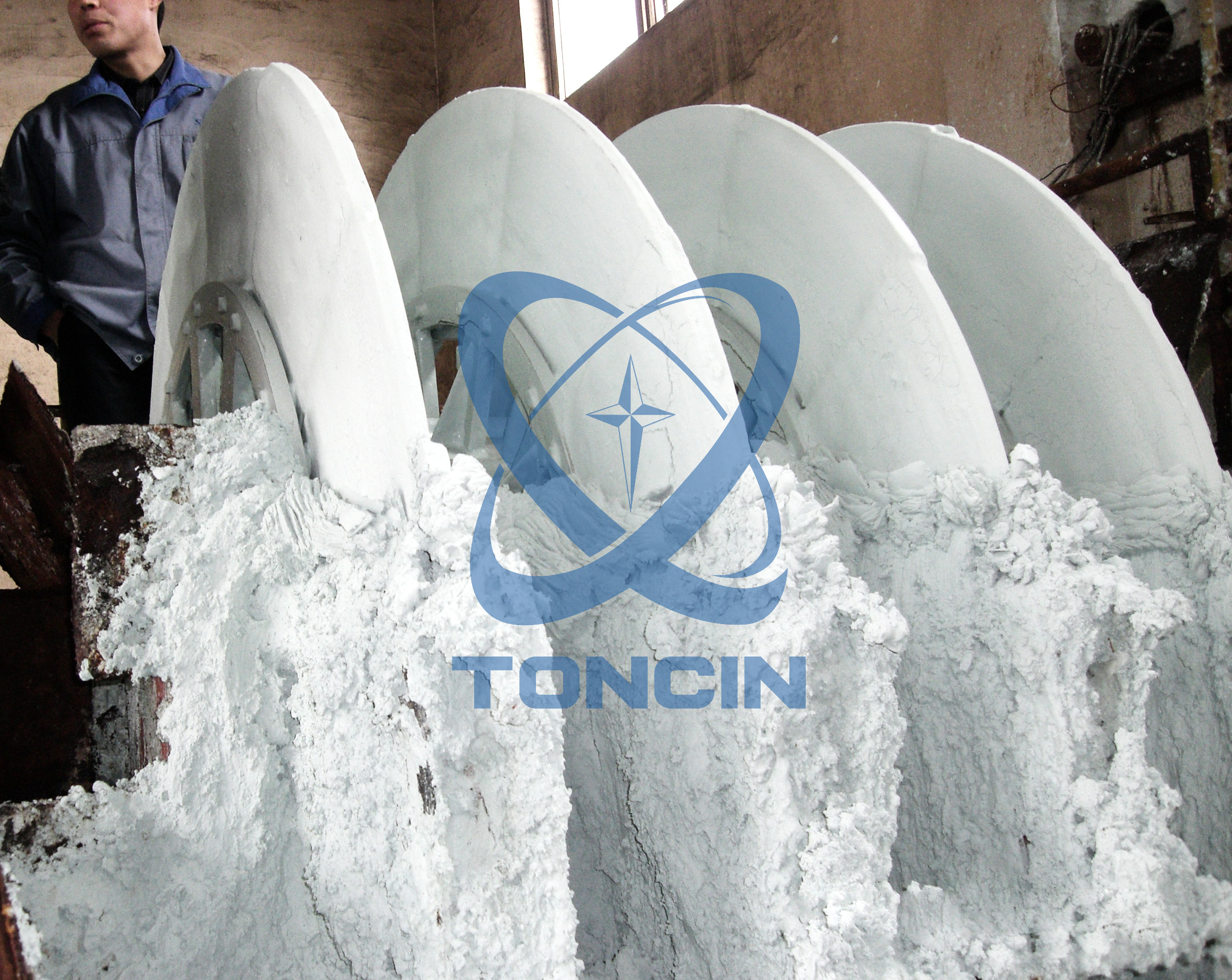

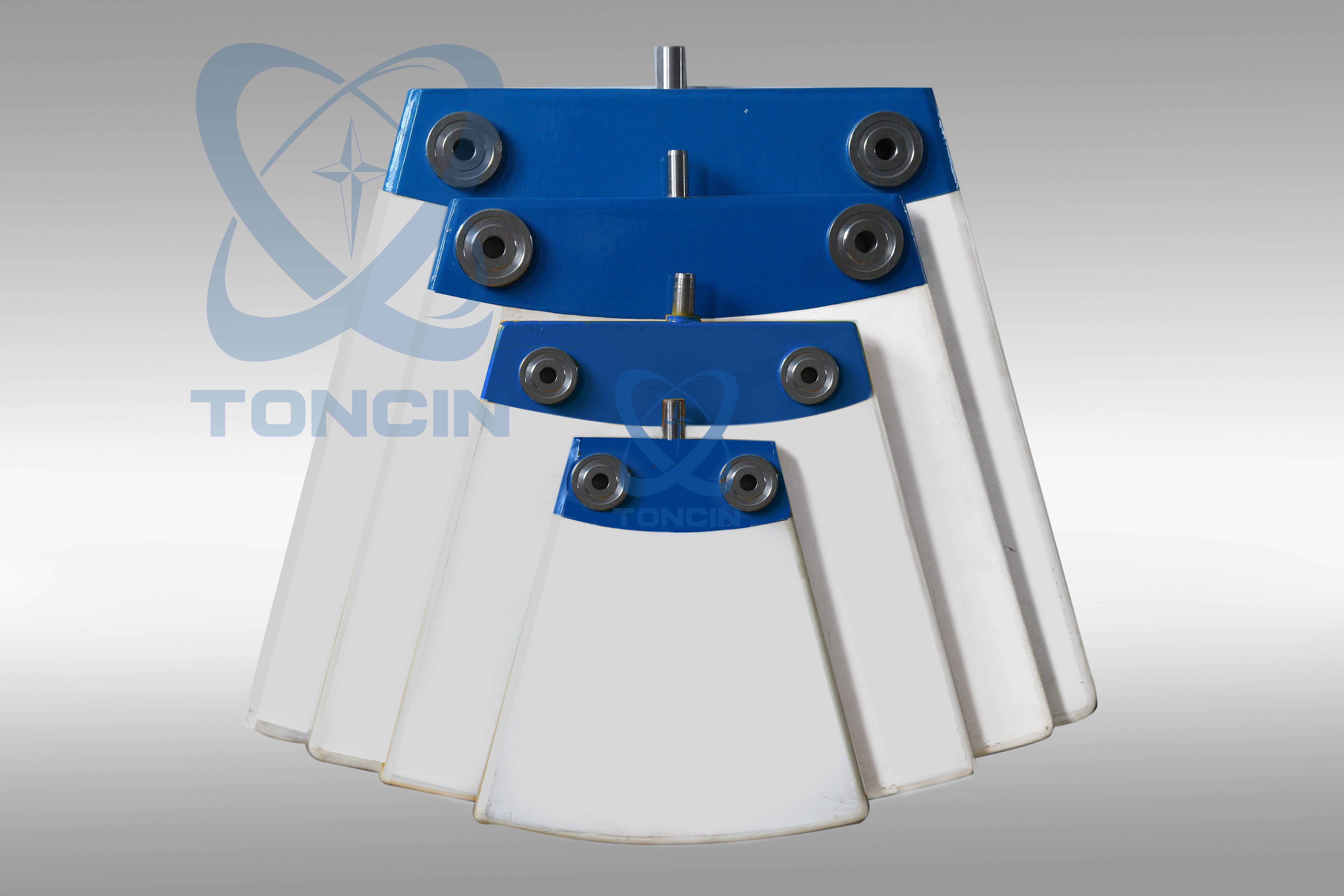

The TC series ceramic vacuum filter represents an innovative and highly efficient filtration equipment designed for energy-saving solid-liquid separation through the use of vacuum and ceramic plates featuring micro-holes. Constructed from corundum, a material resistant to extreme temperatures, these plates exhibit prolonged operational life. The micro-holes exclusively permit the passage of liquid, preventing the flow of air and solids. As the ceramic plates immerse into the slurry cabin, filtrate is drawn through them, leading to the formation of cakes on the plate surfaces.

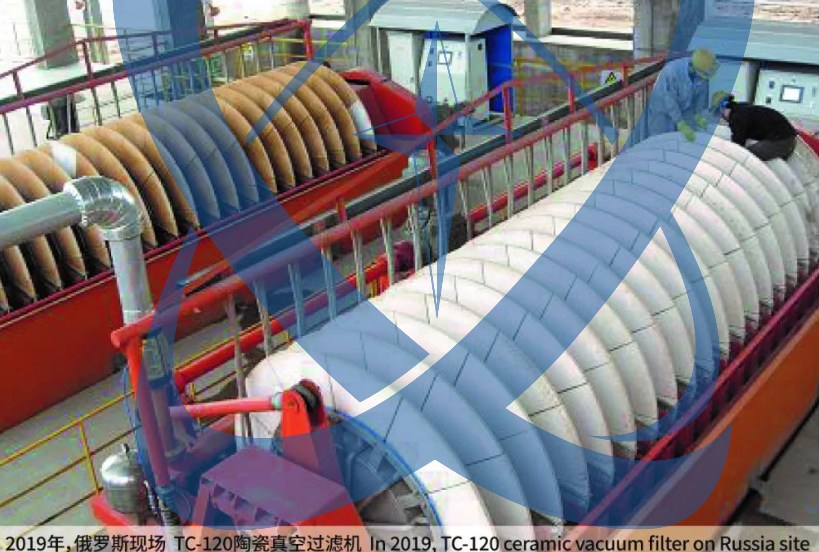

This equipment, tailored for mining applications, ensures elevated productivity and superior process outcomes. It excels in efficient dewatering, offering competitive investment costs, low installation and operating expenses, and enhanced safety measures. Widely applied in the separation of selected and tailings mines of nonferrous, ferrous, and less-common metals, as well as oxide electrolysis residue and slag in chemical and environmental protection processes. It accommodates materials with fineness ranging from -200 to -450 meshes, including various superfine materials.

(The TC series precision ceramic vacuum filter, integrating electromechanical components, micro-porous ceramics, and ultrasonic technology, represents an advanced filtration system relying on vacuum suction and capillary action for solid-liquid separation. Extensively employed in non-ferrous metals, rare metals, ferrous metals, and nonmetals mining for mineral concentrates and tailings dewatering. Additionally, it plays a crucial role in the dehydration of oxides, electrolytic slag, leach slag, and chemical industry processes. It finds application in environmental protection, handling sewage, sludge, and waste acid treatment. The equipment processes materials ranging from -200 to -450 meshes in fineness, encompassing a variety of ultra-fine materials.)

Our product has found extensive applications in the separation of selected mines and tailings in nonferrous, ferrous, and less-common metals, as well as in the treatment of oxide electrolysis residue and chemical slag, contributing to fields such as environmental protection. The material fineness ranges from -200 to -450 meshes, accommodating various superfine materials.

Product Specifications:

English

English